13-4

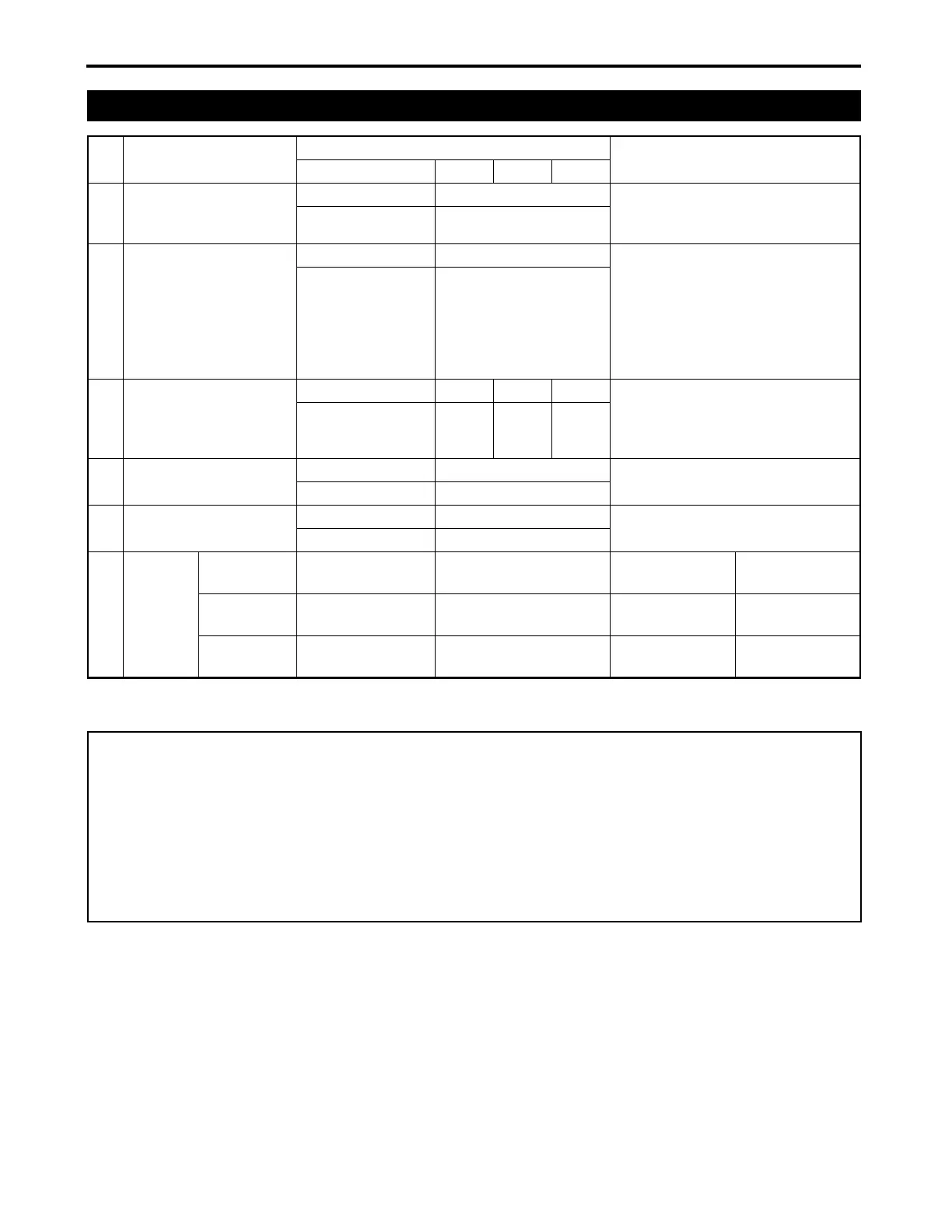

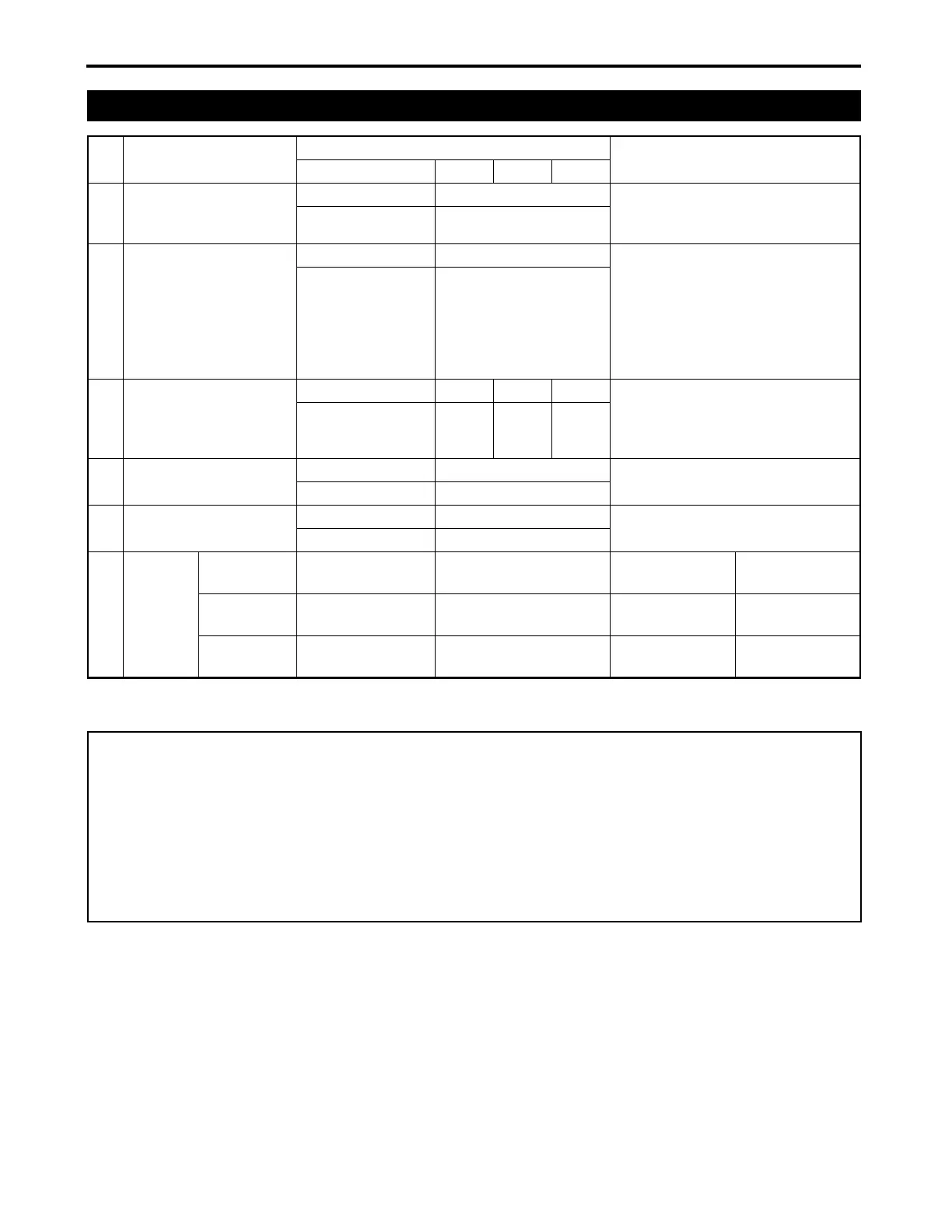

13. MAINTENANCE

SA221/324/424 Operation Manual

(Specifications and design are subject to change without prior notice for improvement.)

3. Lubricants

No. Locations

Capacities

Lubricants

UNIT SA221 SA324 SA424

1 Fuel

L 23.0 No.2-D diesel fuel

No.1-D diesel fuel if temperature is

below 14°F (-10°C)

US gal 6.1

2Coolant

L 2.8 High Quality Permanent Type

Antifreeze (Ethylene Glycol with

corrosion and rust inhibitor

chemicals)

Coolant Mixture Ratio

Distilled Water 50%: Antifreeze

50%

US qt. 3.0

3

Engine crankcase

(with filter)

L 2.9 3.4 3.4 API Service Classifications CD or

higher

SAE 10W-30, SAE 10W-40 or

SAE 15W-40

US qt. 3.1 3.6 3.6

4

Transmission hydraulic

oil

L15.5

Hydraulic/Transmission Fluid

(TF 500A)

US gal 4.1

5 Front axle gear oil

L3.0

SAE 80W-90 gear oil

US qt. 3.2

6Greasing

Tie rod

No. of greasing

point

2

Until grease

overflows

NLGI GRADE

No.2

Brake pedal

No. of greasing

point

1

Until grease

overflows

NLGI GRADE

No.2

HST pedal

No. of greasing

point

1

Until grease

overflows

NLGI GRADE

No.2

*NOTE

●Immediately after purchasing the tractor:

• adjust the coolant mixture ratio of the coolant and water to suite the local climate

• the preceding practice assists in making the tractor function efficiently

●The coolant can remain unchanged for a period of 2 years:

• if during the period the tractor is operated for less than 1200 hours

• if the tractor is operated for more than 1200 hours during the period, the coolant has to be replaced during

flushing of the system

●After pouring the coolant, run the engine for a short period to mix the two fluids thoroughly.

SA221_324_424_OperatorsManual.book 4 ページ 2018年6月4日 月曜日 午後5時19分

Loading...

Loading...