3. Cabling

3-4

TI 32P01J10-01EN

Cable Terminals

Use the specied solderless terminals and sleeves for pressure clamp terminal on the end of

terminal-connected cables, providing low contact resistance, high durability, and low aging.

Solderless Lug

CAUTION

• Be sure to use solderless terminals with insulating sheath.

• Use solderless terminals and crimp tools from the same manufacturer.

• Use appropriate crimp tools meeting the cable size.

Figure Solderless Terminal with Insulating Sheath

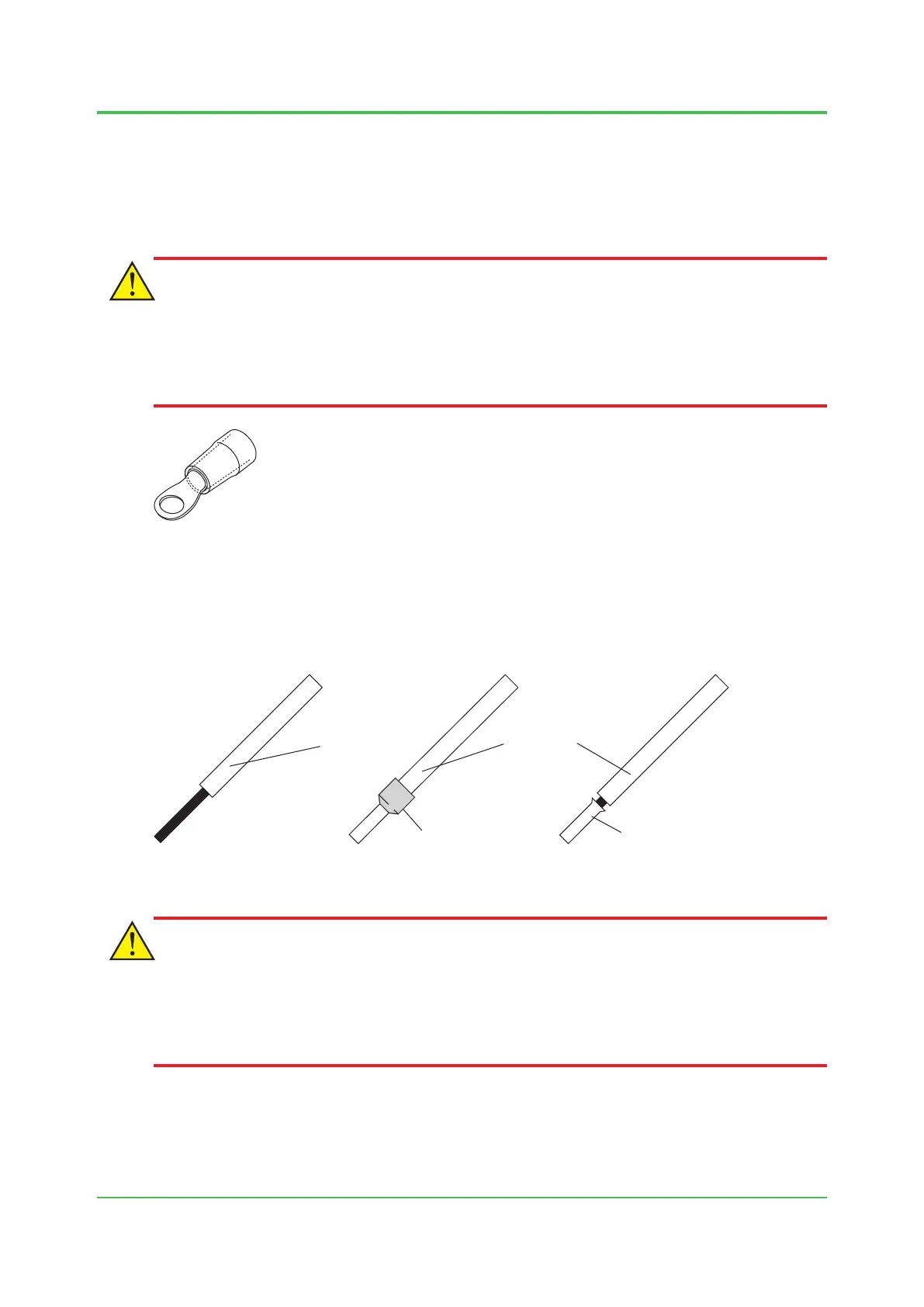

Sleeve for pressure clamp terminal and spring clamp terminal

When connecting the process I/O signal to the pressure clamp terminal of the I/O module, strip

the cable coating (without a sleeve) or attach a sleeve to the cable.

Signal cable Signal cable

Without sleeve With sleeve

Sleeve with isolation

cover

cover

Figure Sleeve for Pressure Clamp Terminal and spring clamp terminal

CAUTION

• Use a sleeve for pressure clamp terminal and a clamp tool from the same manufacturer.

• Use a sleeve for pressure clamp terminal and a clamp tool which suit the cable size.

• Use a sleeve which meet the DIN 46228 standards.

Bending radius of the cable

When connecting a cable to a system instrument, ensure to secure the minimum bending radius

of the cable.

The minimum bending radius is either the value shown in the cable manufacturer’s specications

or six-fold of the cable conductor diameter, whichever is bigger should be applied.

Oct. 25, 2016-00

Loading...

Loading...