General Instruction Manual

Troubleshooting

Display deviating

82 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

10.3 Display deviating

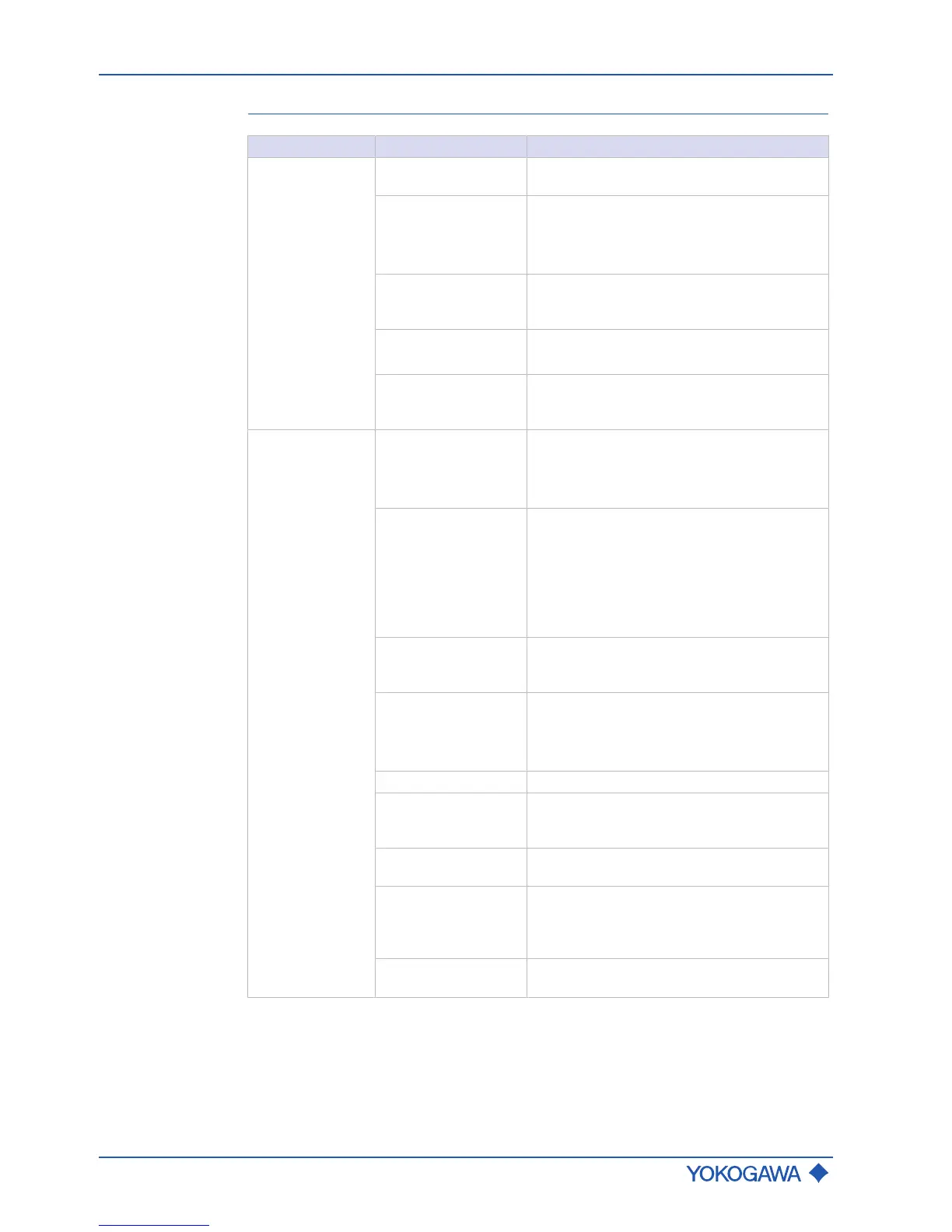

Malfunction Possible causes Remedy

Flow rate dis-

played deviates

from actual flow

rate

Zero point set

incorrectly

– Set zero point, see [}74]

Highest and lowest

value for mass flow

set incorrectly

– Match settings of flow meter and reading

system.

– Check LRV and URV process parame-

ters, see software instruction manual.

Measuring tubes not

completely filled with

fluid

– Correct installation, see [}27]

Bubbles in fluid

– Check pipe and installation, see [}27].

– Correct installation, see [}27]

Connecting cable in-

correctly connected

for remote type

– Check cable connections and correct, if

necessary, see [}46].

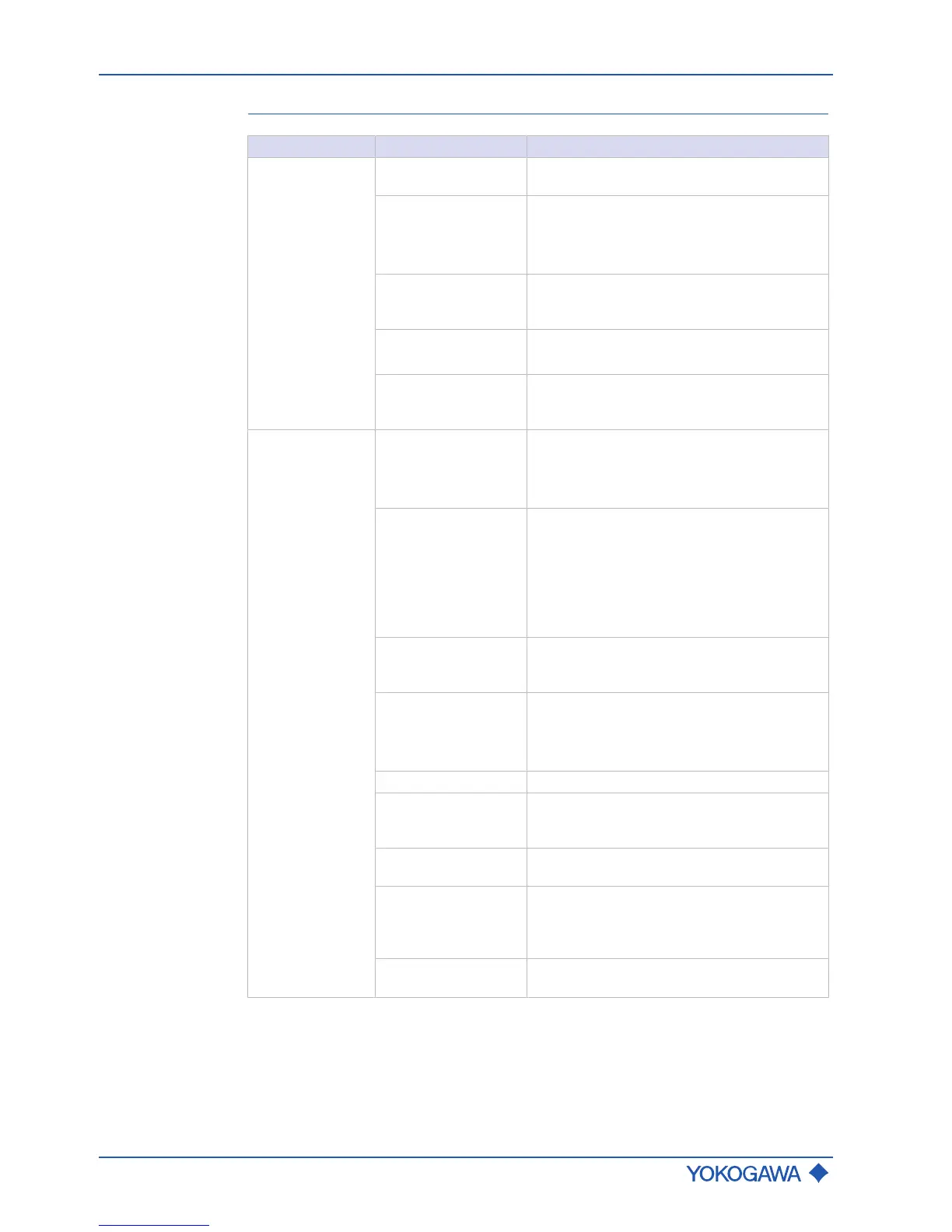

Density displayed

deviating from

actual density

Density unit, highest

and lowest value for

density set incorrectly

– Match settings of flow meter and reading

system.

– Check LRV and URV process parame-

ters, see software instruction manual.

Fixed density

– Check whether the Val sel parameter is

set correctly. If a fixed value is selected,

ensure that the parameter Fix val is set

correctly, see software instruction

manual.

– Set parameter Val sel to Meas val,

see software instruction manual.

Analog output trim

was performed incor-

rectly

– Correctly perform trimming, see

applicable software instruction manual.

No electrical

grounding

– Ground transmitter and sensor,

see [}44].

– Check correct connection of connecting

cable shield on transmitter.

Bubbles in fluid

– Check pipe and installation, see [}27].

Connecting cable in-

correctly connected

for remote type

– Check cable connections and correct, if

necessary, see [}46].

Faulty temperature

measurement

– Check temperature measurement circuits

TP1 – TP3 of connecting cable.

Corrosion and erosion

– If corrosion or erosion due to corrosive

fluids is suspected, contact Yokogawa

and have density and mass flow recali-

brated, if necessary.

Contaminated

measuring tubes

– Clean measuring tubes.

Loading...

Loading...