404912-UIM-A-0508

Johnson Controls Unitary Products 5

DUCT CONNECTIONS

NOTE: The electric heat accessory should be installed before the sup-

ply air duct is attached to the supply air openings. Refer to the electric

heater kit instructions for proper installation.

Air supply and return may be handled in one of several ways best

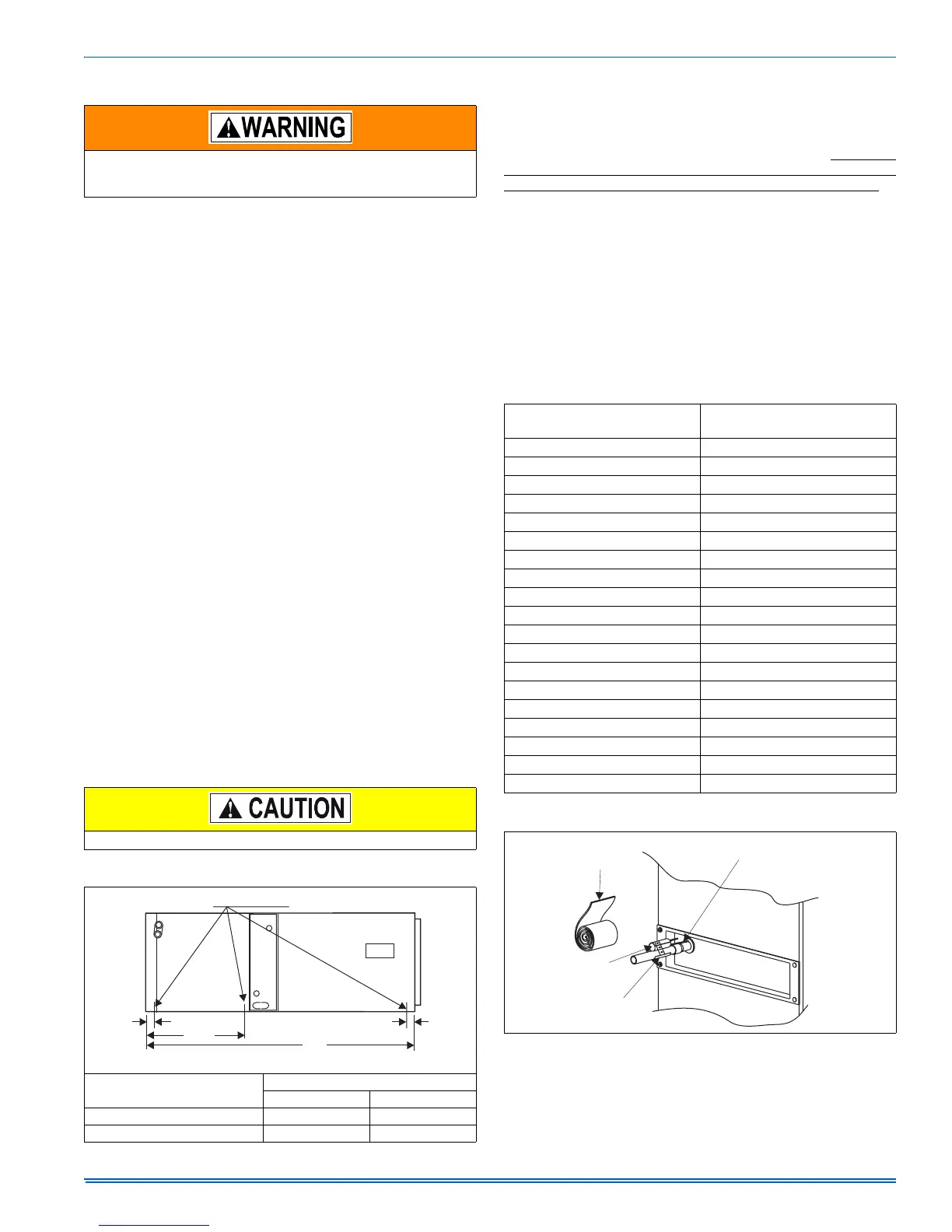

suited to the installation. See Figure 4 for dimensions for duct inlet and

outlet connections.

The vast majority of problems encountered with combination heating

and cooling systems can be linked to improperly designed or installed

duct systems. It is therefore highly important to the success of an instal-

lation that the duct system be properly designed and installed.

Use flexible duct collars to minimize the transmission of vibration/noise

into the conditioned space. If electric heat is used, non-flammable

material must be used.

Where return air duct is short, or where sound may be a problem,

sound absorbing glass fiber should be used inside the duct. Insulation

of duct work is a must where it runs through an unheated space during

the heating season or through an uncooled space during the cooling

season. The use of a vapor barrier is recommended to prevent absorp-

tion of moisture from the surrounding air into the insulation.

The supply air duct should be properly sized by use of a transition to

match unit opening. All ducts should be suspended using flexible hang-

ers and never fastened directly to the structure. This unit is not

designed for non-ducted (freeblow) applications. Size outlet plenum or

transition to discharge opening sizes shown in Figure 4.

Duct work should be fabricated and installed in accordance with local

and/or national codes. This includes the standards of the National Fire

Protection Association for Installation of Air-Conditioning and Ventilat-

ing Systems, NFPA No. 90B.

AIR FILTERS

Air filters must be field supplied. A 1" filter access rack has been built

into the unit. See Figure 4. Remove filter access cover shown. Install

proper size filter. Standard 1" size permanent or throw away filter may

be used, or, permanent washable filters are available using model num-

bers: 1PF0601, 602, 603BK. See Table 3 for filter size.

SUSPENSION KITS

A suspension kit is available. Models 1BH0601 (unit sizes 018-060) is

designed specifically for the units contained in this instruction (upflow

application only). For installation of these accessory kits, see the

instructions packed with the kit.

For suspension of these units in horizontal applications, it is recom-

mended to use angle steel support brackets with threaded rods, sup-

porting the units from the bottom, at the locations shown in Figure 5.

COIL METERING DEVICES

The coil in this Air Handler unit will have a TXV metering device

installed at the factory.

Air Handlers can be ordered with an R-22 TXV factory installed which

can be easily converted to R-410A by changing the bolt-on TXV. Refer

to the TXV metering device section for installation notes.

Air Handler “Flex-coils” are also available without a factory installed

metering device. For added application flexibility an orifice metering

device, R-22 TXV or R-410A TXV should be installed on the flex-coil in

the field to meet your refrigerant choice.

.

TXV Metering Device

Please refer to Table 2 to verify which TXV is installed in this Air Han-

dler unit and that this AHU is a valid system match for the AC or HP unit

installed.

Use 1/2" screws to connect ductwork to bottom of unit. Longer

screws will pierce the drain pan and cause leakage. If pilot holes

are drilled, drill only though field duct and unit bottom flange.

Equipment should never be operated without filters.

Units

(Nominal Tons)

Dimension

WW XX

018, 024, 030, 036, 040, 042 14” 40-3/4”

045, 048, 060 19-1/2” 50-3/4”

FIGURE 5: Typical Horizontal Installation

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTAL APPLICATIONS*

2

WW

XX

1-1/2

NOTE: USE SUPPORTS UNDER UNIT.

TABLE 2:

Installed TXV Sizes

Indoor

Coil Model

Factory Installed

Metering Device

F4FP024H06T2A TXV 2A

F4FP024H06T2B TXV 2B

F4FP024H06T3X None

F4FP030H06T2A TXV 2A

F4FP030H06T3X None

F4FP036H06T2A TXV 2A

F4FP036H06T3X None

F4FP040H06T2A TXV 2A

F4FP040H06T2C TXV 2C

F4FP040H06T3X None

F4FP042H06T2A TXV 2A

F4FP042H06T2C TXV 2C

F4FP042H06T3X None

F4FP045H06T2C TXV 2C

F4FP045H06T3X None

F5FP048H06T2C TXV 2C

F5FP048H06T3X None

F5FP060H06T2C TXV 2C

F5FP060H06T3X None

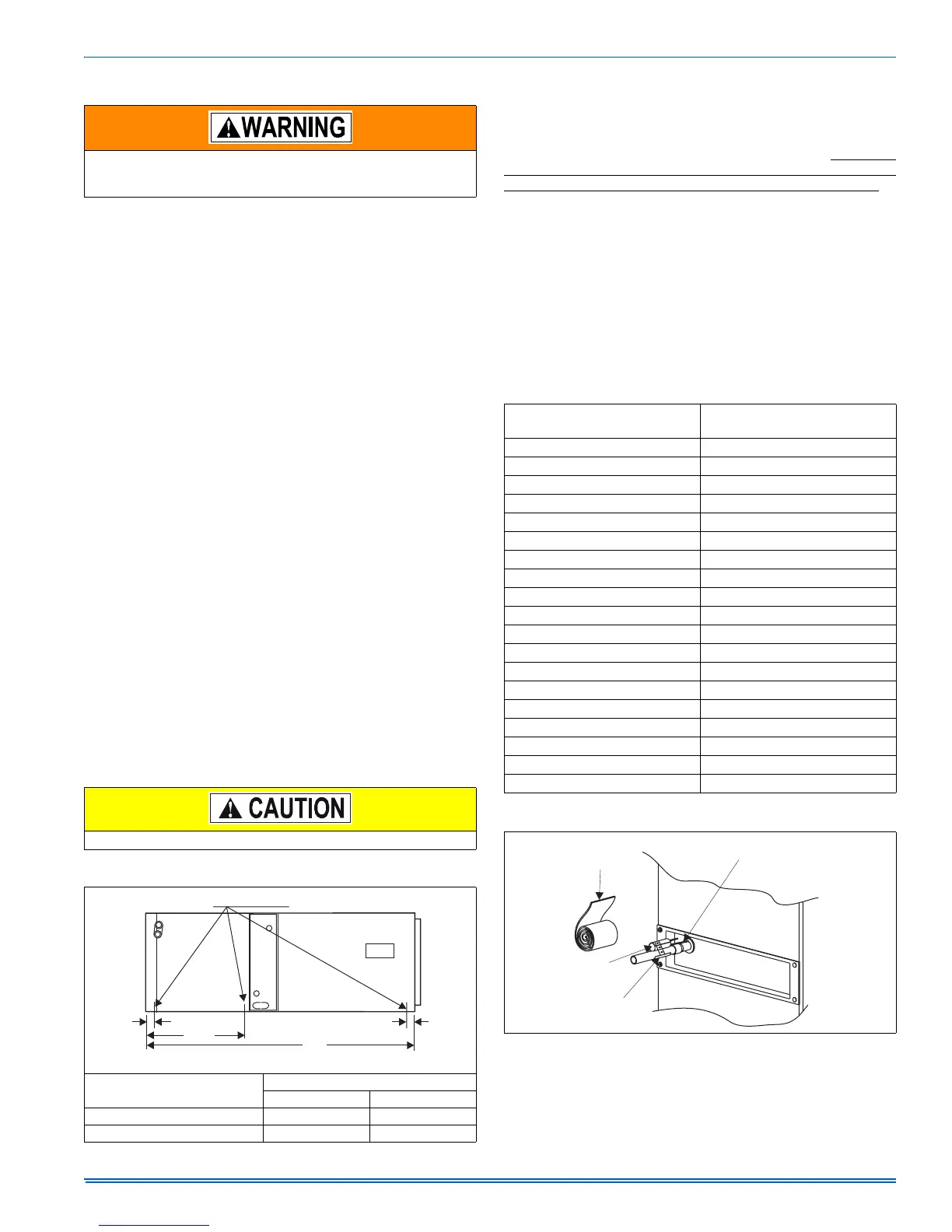

FIGURE 6: TXV Bulb Installation

INSULATION

ROLL

EXPANSION

BULB

EXPANSION

BULB CLAMP

EXPANSION

BULB TUBING

Loading...

Loading...