YORK MINISPLIT FLOOR/CEILING Code 035T80012-000

18

FLOOR/CEILING

TEST OPERATION

CHECK THIS ITEM BEFORE START OPERATION

Outdoor

• Check the flare nut connections, valve stem cap connections and service cap connections for gas leak with a leak

detector or soap water.

Indoor

• Check the unit is firmly fixed.

• Check the connecting pipes are tighten securely.

• Check the pipe insulation.

• Check the drainage.

• Check the connection of the grounding wire.

SYSTEM TEST DIAGNOSTICS

Test Operation Mode

1) This is a diagnostic mode to check the functioning of a unit. In installations with multiple units it is possible to start

the Test Operation Mode in all the units sequenially and run the test mode in parallel, thus shortening the time for

service calls. By consulting the status of each unit a diagnosis can be made of any problems or normal operation

can be verified.

2) Test Operation mode carries out the following operational sequence and then returns to the normal mode after

the Test operation is finished. In the case of Cool only systems the sequence will be completed after STEP 2. If a

problem is encountered during Test Operation mode the unit will indicate this as shown in the chart below and the

LED Display will flash according to the LED Diagnostic Codes. If an error occurs the reset shall be when the EMS

switch is pressed for more than 1 second and less than 10 seconds. Upon release, the operation shall return to

normal and the unit shall be off.

3) To start this mode, the emergency switch must be pressed for at least 10 seconds and released while in normal

operation mode. To interrupt this mode, press the emergency switch again for at least 10 seconds.

4) If a failure occurs during the test mode operation the unit the board shall:-

- Stop the operating of compressor

- Indicate the error by the lamp out puts

- Remain in that condition until reset

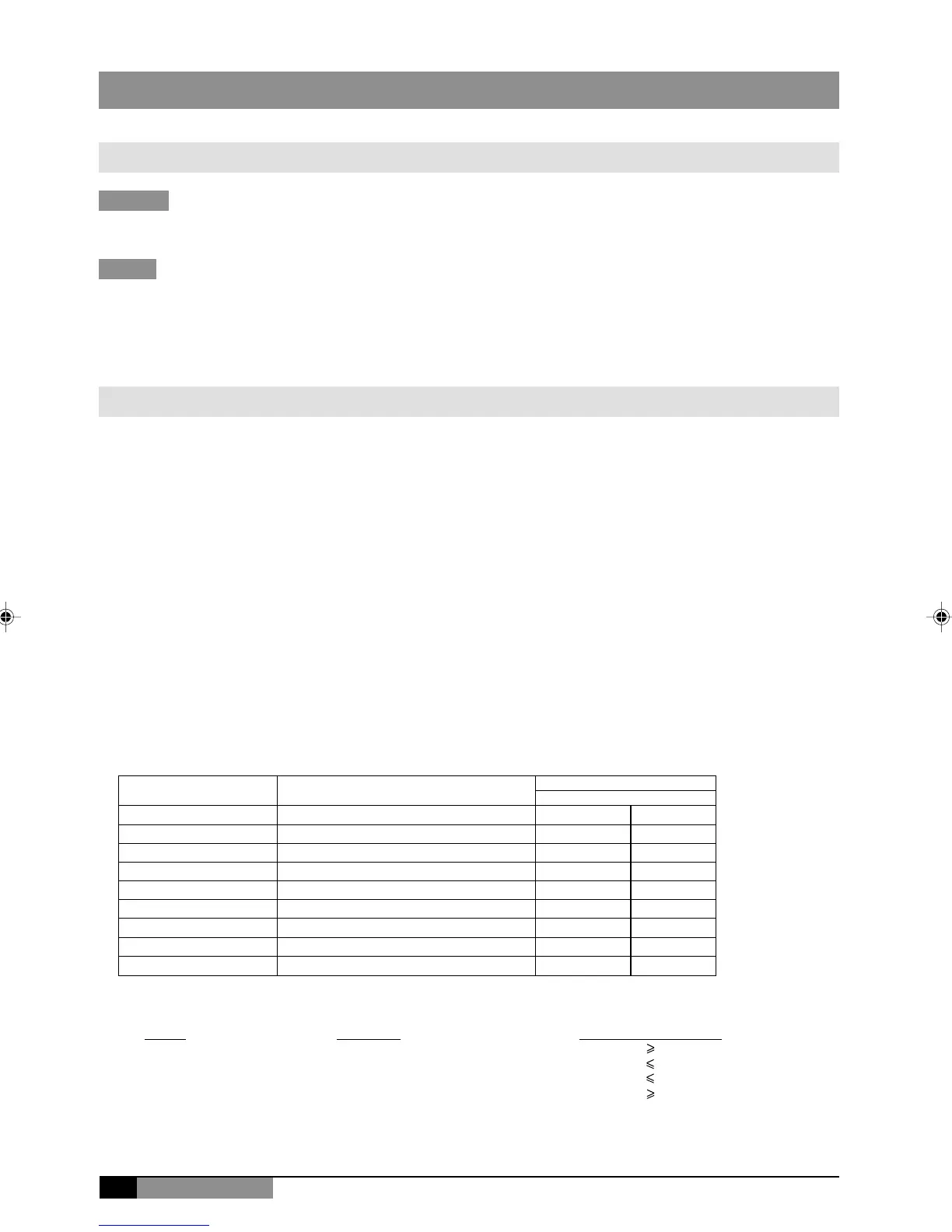

Test Operation Mode

Any timer settings entered before the start of the Test Operation Mode will not be affected by the Test Operation Mode.

Failure display follows the conditions below.

Status Operation Terminating Condition

Low HP temp < 20˚C fan stop and louver full open Coil temp

20˚C

Coil temp > 40˚C (cooling) fan stop and louver full open Coil temp

40˚C

Overheat > 62˚C (heating) louver full open Coil temp

50˚C

Anti Freeze louver full open Coil temp

5˚C

Low voltage halt return to normal range

Sensor fail stop system reset

Cooling fail stop system reset

Heating fail stop system reset

In cool only mode Input

Operation time

Minutes

STEP 1 Fan only high 3

STEP 2 Cool mode : fan high 4 Diagnostic

Cool mode : fan med 2

Cool mode : fan low 3

STEP 3 Stop Waiting 3

STEP 4 Heating mode : fan high 4 Diagnostic

Heating mode : fan med 2

Heating mode : fan low 3

STEP 5 Waiting 3

03_install.p65 19/4/02, 14:4818

Loading...

Loading...