37

FORM 160.47-NOM3

YORK INTERNATIONAL

CAPACITY CONTROL

Refer to the Capacity Control Piping Schematic piping,

figure 23.

Evaporator fluid Set Point. When the leaving evapora-

tor fluid temperature is beyond the range of the set point

value a signal is sent to the relay output board. A signal

is sent from the relay output board to energize the 4-

way valve directional solenoid valves.

When Solenoid Valve B is energized the slide valve be-

gins to move in the load direction. The 4-way direc-

tional valve opens Port P to Port B and Port A to Port T.

Oil pressure from the oil circuit flows into the 4-way

solenoid valve sub-plate manifold at Port P. Oil pres-

sure flows through the sub-plate manifold block and out

Port B to Compressor Port SC-2. Simultaneously, oil

flows out of Compressor Port SC-1 into Port A on the

sub-plate manifold, through the sub-plate manifold block

and out of the sub-plate manifold block at Port T to

suction pressure.

When the Solenoid Valve A is energized, the slide valve

will move in the unload direction. The 4-way directional

valve opens Port P to Port A and Port B to Port T. See

Figure 24. High pressure oil flows into Compressor Port

SC-1 and oil is relieved out of Compressor Port SC-2 to

suction pressure.

A slide valve potentiometer is used to provide feedback

to the microprocessor to display slide valve position as

a percentage of full load.

Four manual isolation valves are incorporated into the

4-way solenoid sub-plate to isolate the 4-way directional

valve for service. Remove the steel hexagonal caps to

gain access to the service valve stem. Use a refrigera-

tion service valve wrench to close or open the valves.

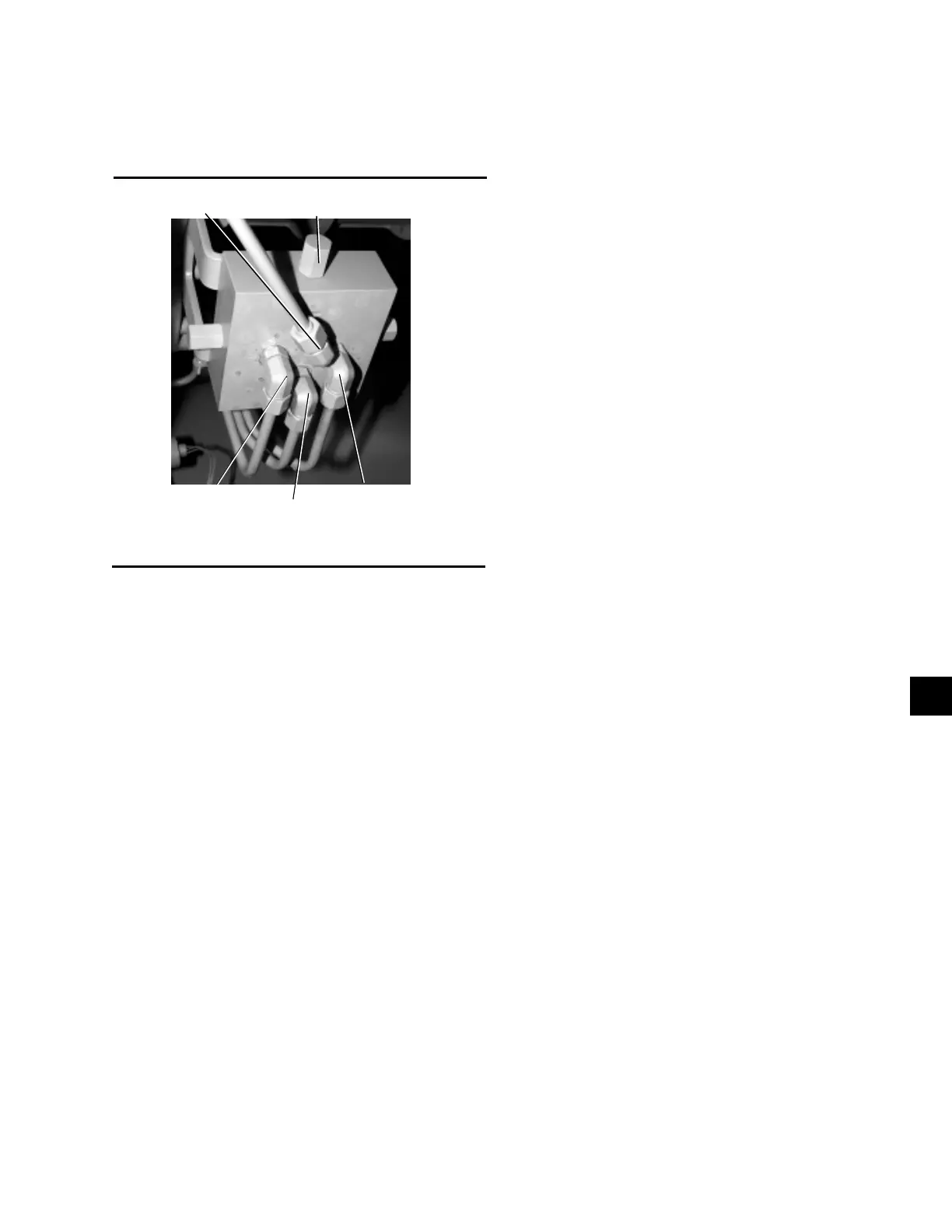

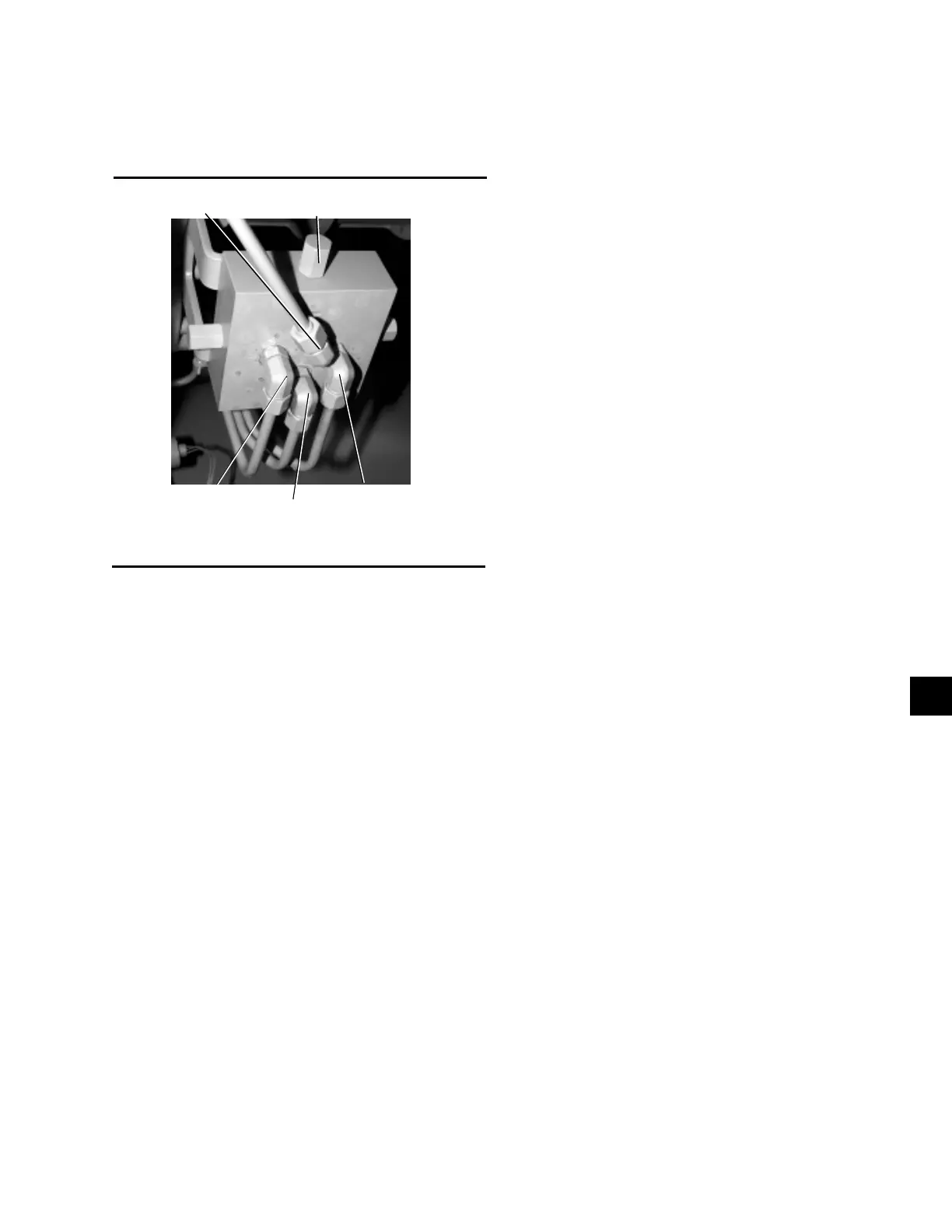

FIG. 24 – 4-WAY DIRECTIONAL VALVE SUBPLATE

2

Capacity control is accomplished by using differential

pressure to move the slide valve. As the slide valve is

moved axially between the compressor rotors the vol-

ume of gas pumped by the compressor is changed to

match the system requirements.

Leaving evaporator fluid temperature is continuously

monitored by the microprocessor. The Leaving Evapo-

rator fluid temperature is compared to the Leaving

SERVICE ISOLATION

VALVE CAP

PORT “T”

PORT “A”

PORT “P”

PORT “B”

2

Loading...

Loading...