JOHNSON CONTROLS

174

FORM 150.67-NM2

ISSUE DATE: 01/31/2019

SECTION 8 – UNIT OPERATION

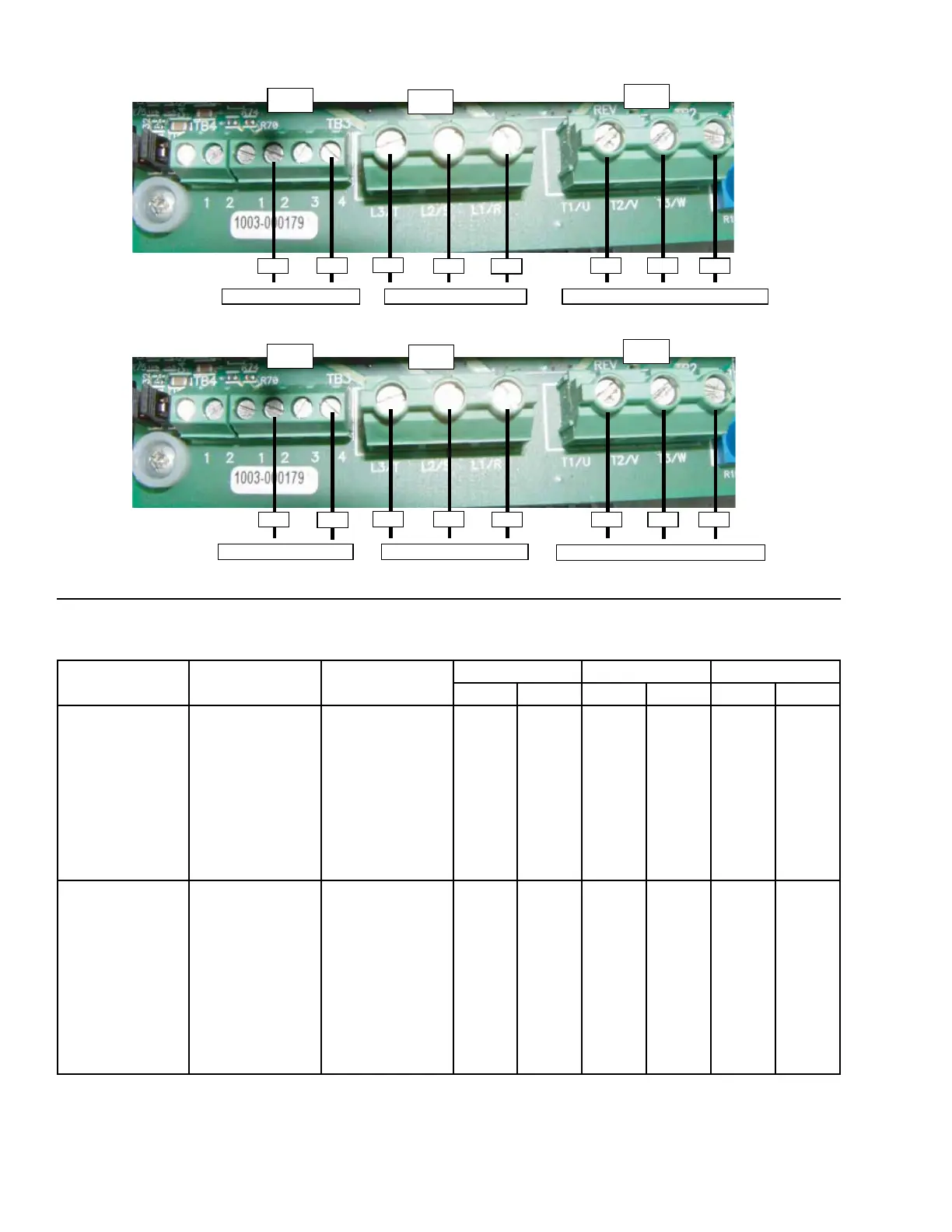

TB3

TB1

TB2

TO PANEL 10M TO FAN #2 (EXISTING HARNES S)TO MICROBOARD (P7)

251250

252

250A

251A252A

WHT

BLK

TB3

TB1

TB2

TO PANEL 10M TO FAN #2 (EXISTING HARNES S)TO MICROBOARD (P7)

251

250

252

250A

251A252A

WHT

BLK

TB3

TB1

TB2

TO PANEL 7M TO FAN #1 (EXISTING HARNESS)

TO MICROBOARD (P4)

151

150

152

150A

151A

152A

WHT

BLK

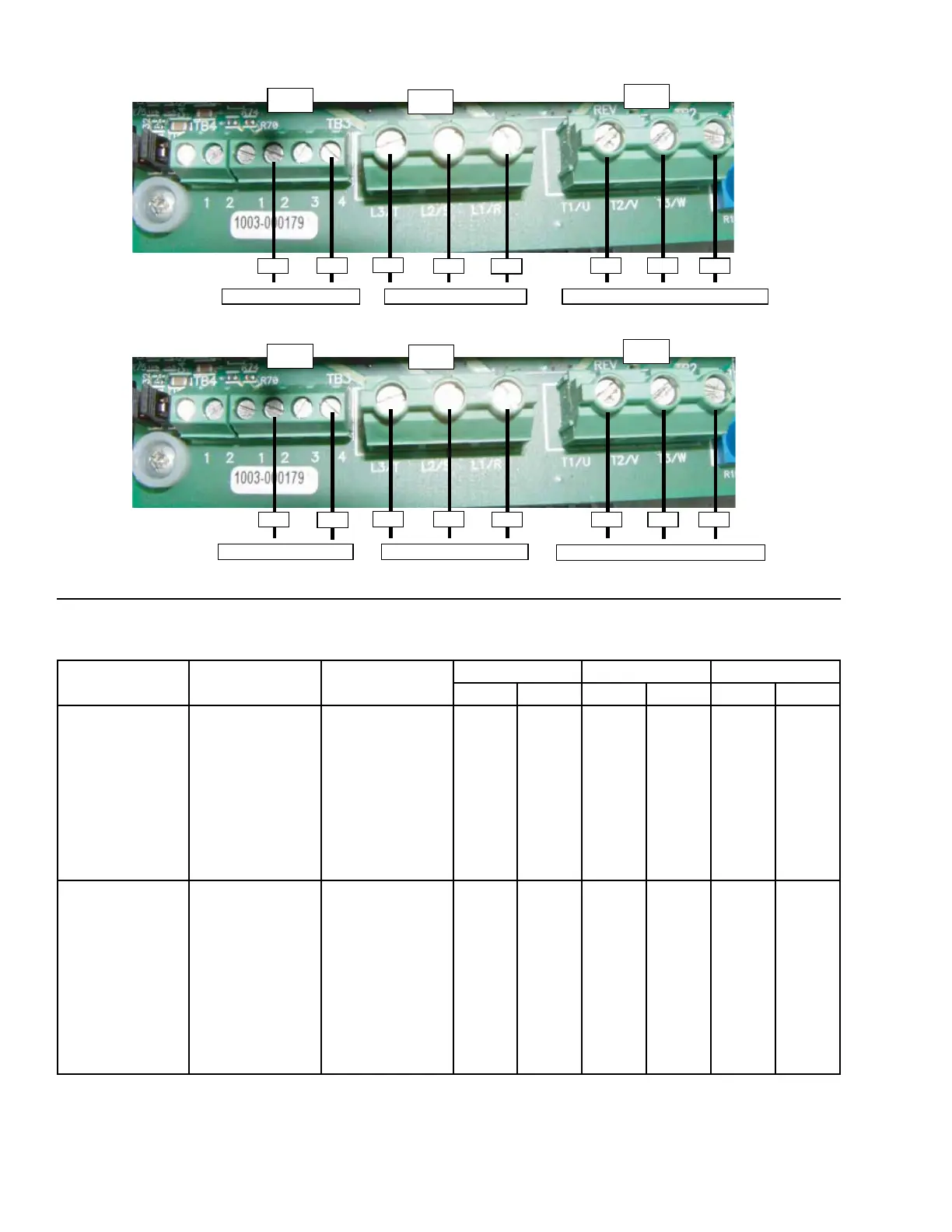

TB3

TB1

TB2

TB3

TB1

TB2

TO PANEL 7M TO FAN #1 (EXISTING HARNESS)

TO MICROBOARD (P4)

151

150

152

150A

151A

152A

WHT

BLK

FIGURE 58 - INVERTER WIRING

LD11302

TABLE 28 - YCAL0043-0066 VFD LOW AMBIENT OPTION – CONDENSER FAN CONTROL OPERATION

FAN STAGE ON OFF

CONTACTOR MICROBOARD FAN #

SYS 1 SYS 2 SYS 1 SYS 2 SYS 1 SYS 2

1:

VFD Control

(1 Fan

Variable Speed)

Fan Speed

Is A Function Of

Discharge

Pressure.

When The Liquid

Line Solenoid Is

Energized, Speed

Increases With

Pressure

FAN Will Turn

Off or Turn Very

Slowly When Pres-

sure Drops Below

260 PSIG.

7M 10M TB7-3 TB10-9 1 2

2:

1 Fan VFD Con-

trol

2nd Fan Full

Speed Under

Contactor Control

425 PSIG, Both

Fans Will Be Run-

ning Full Speed

Discharge

Pressure

< 260 PSIG (Pres-

sure Is

< Fan Control ON

Pressure of

425 PSIG Minus

Fan Differential

Pressure of 125

PSIG = 300 PSIG)

7M

&

8M

10M

&

11M

TB7-3

and

TB7-10

TB10-9

and

TB10-

10

1

&

3

2

&

4

Loading...

Loading...