157YORK INTERNATIONAL

FORM 201.18-NM1 (102)

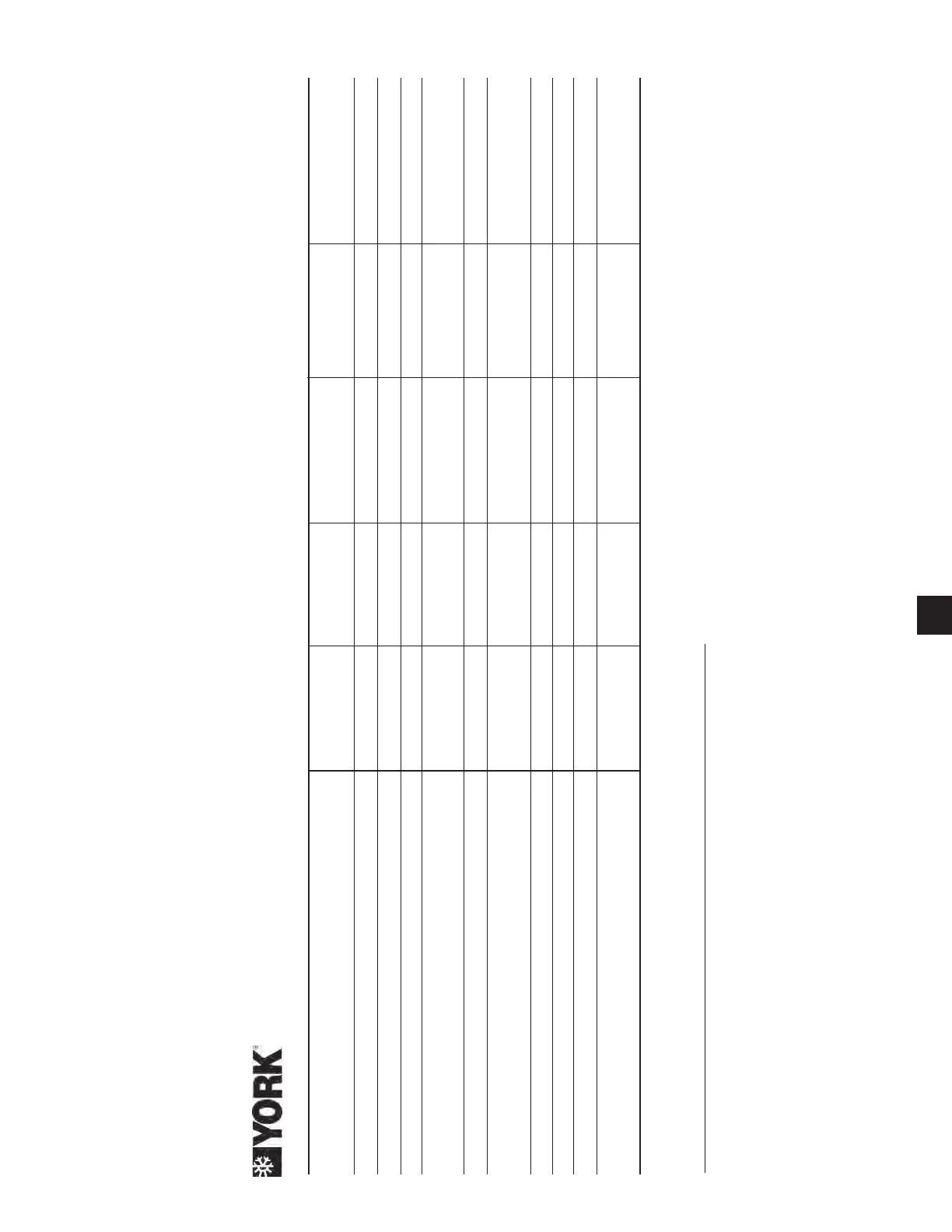

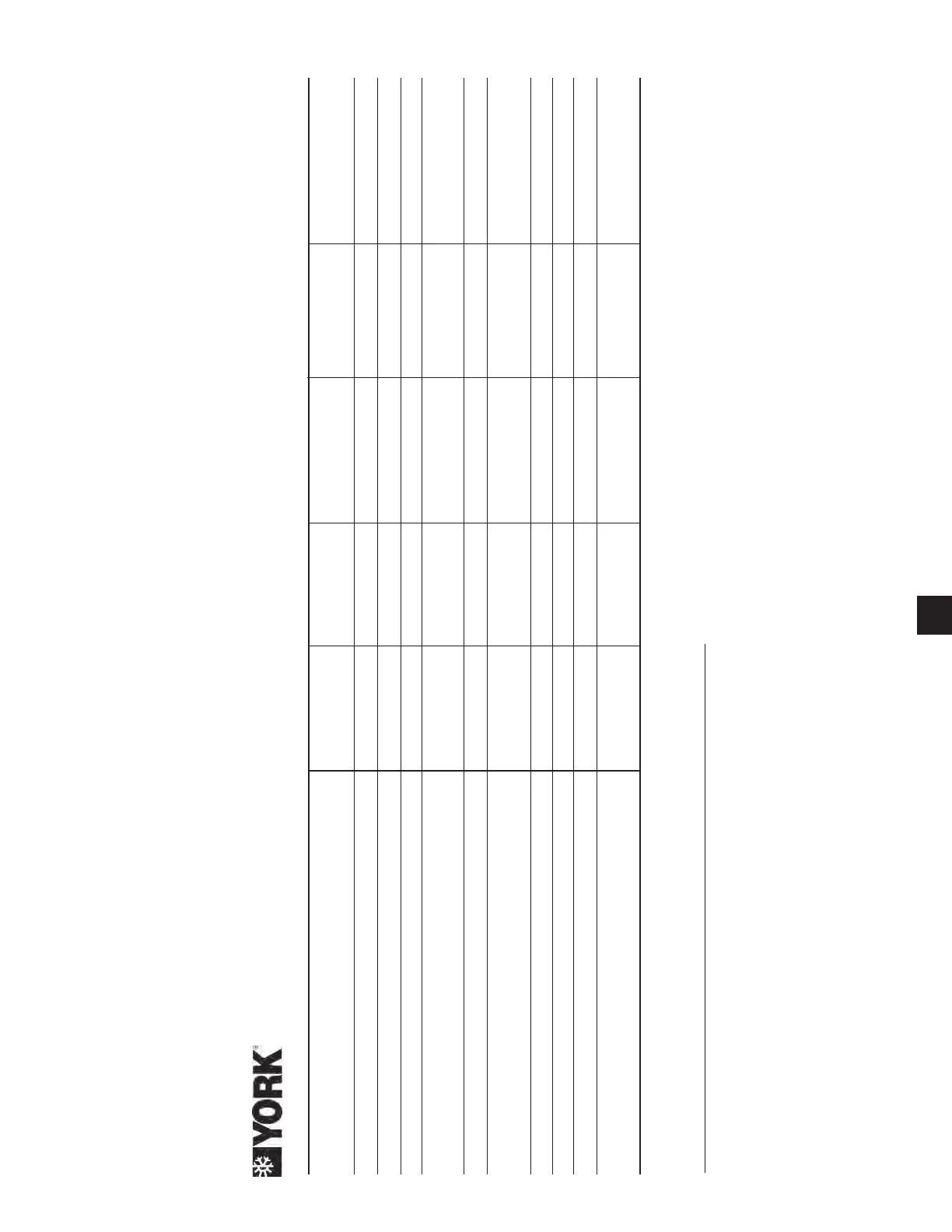

PROCEDURE WEEKLY QUARTERLY SEMI-ANNUALLY YEARLY

EVERY

___ HOURS

Check oil level in oil separator sight glass X

Check liquid line sight glass / moisture indicator X

Record system operating pressures and temperatures X

Check programmable operating setpoints and safety cutouts

and ensure they are correct for particular application.

X

Check condenser coils for dirt/debris and clean if necessary X

Check compressor superheat on evaporator and economizer

TXV’s; Check condenser and economizer subcooling

1

X

Check compressor and cooler heaters for operation X

Sample compressor oil and replace oil if necessary

1

X

Leak check the chiller

1

X

Disconnect power source and lock out; Check tightness of

power wiring connections

1

X

MAINTENANCE REQUIREMENTS FOR YORK YCAS SCREW CHILLERS

*

* Reserved for customer use for any special site determined requirements.

1

This procedure must be performed at the specified time interval by an Industry Certified Technician who has been trained and qualified to work on this type of YORK

equipment. A record of this procedure being successfully carried out must be maintained on file by the equipment owner should proof of adequate maintenance be

required at a later date for warranty validation purposes.

9

Loading...

Loading...