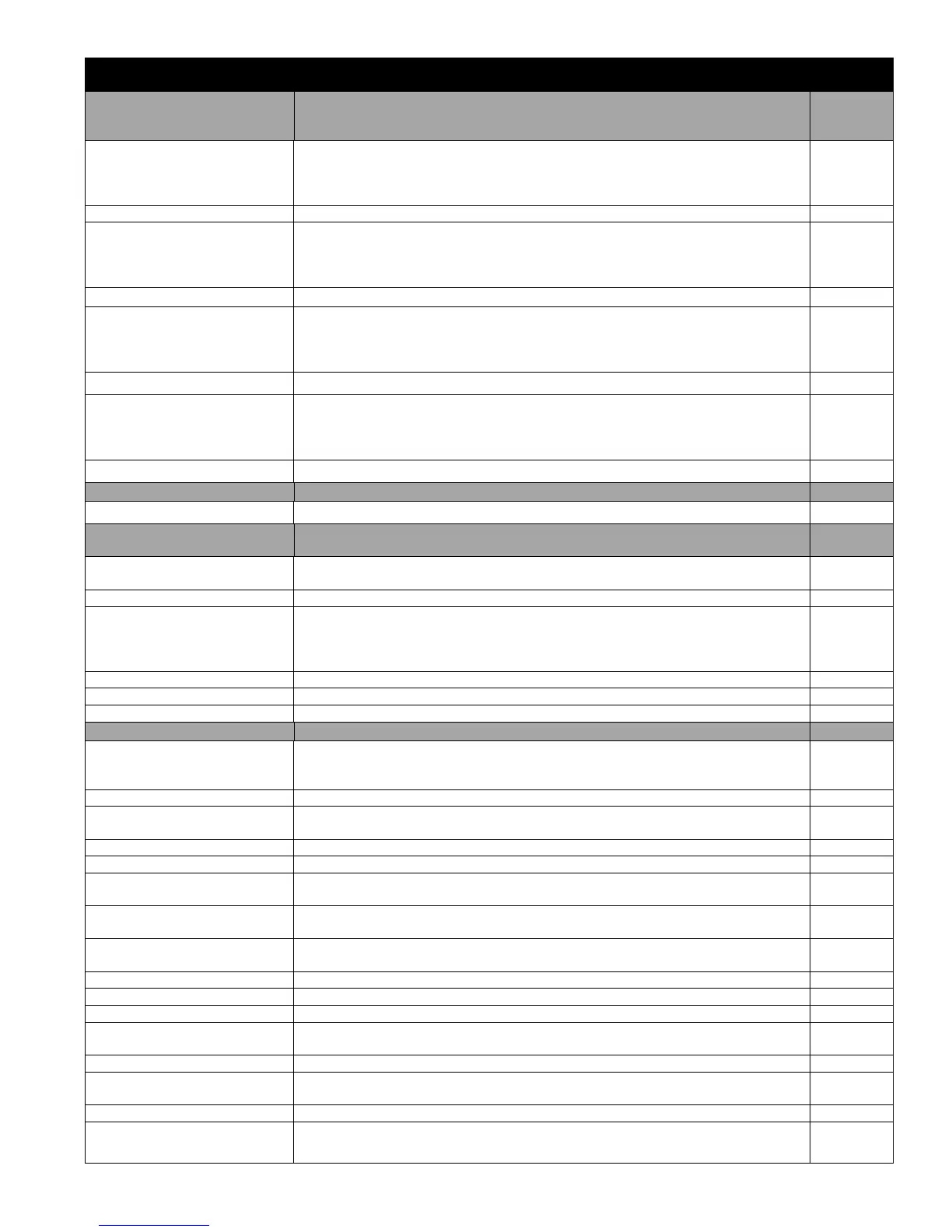

Parameters in the Long parameter mode

Signal supervision. The drive monitors whether certain user selectable variables are within

the user-defined limits. The user may set limits for speed, current etc. Supervision status can

be monitored with relay output. See parameter group 14 RELAY OUTPUTS.

ADJUSTABLE THRESHOLD

1 LOWER LIMIT (ANALOG

OUTPUT 1 / RELAY

OUTPUT 1)

Used in conjunction with some settings of parameter 1501 ANALOG OUTPUT 1 (TERMINAL 8)

FUNCTION SELECT & parameter 1401 USER RELAY 1 OUTPUT (TERMINALS 14, 15 & 16)

FUNCTION SELECT.

ADJUSTABLE THRESHOLD

1 UPPER LIMIT (ANALOG

OUTPUT 1 / RELAY

OUTPUT 1)

Used in conjunction with some settings of parameter 1501 ANALOG OUTPUT 1 (TERMINAL 8)

FUNCTION SELECT & parameter 1401 USER RELAY 1 OUTPUT (TERMINALS 14, 15 & 16)

FUNCTION SELECT.

ADJUSTABLE THRESHOLD

1 LOWER LIMIT (ANALOG

OUTPUT 2 / RELAY

OUTPUT 2)

Used in conjunction with some settings of Parameters 1507 ANALOG OUTPUT 2 (TERMINAL

11) FUNCTION SELECT & 1402 USER RELAY 2 OUTPUT (TERMINALS 17 & 18) FUNCTION

SELECT.

ADJUSTABLE THRESHOLD

1 UPPER LIMIT (ANALOG

OUTPUT 2 / RELAY

OUTPUT 2)

Used in conjunction with some settings of Parameter 1507 ANALOG OUTPUT 2 (TERMINAL

11) FUNCTION SELECT & 1402 USER RELAY 2 OUTPUT (TERMINALS 17 & 18) FUNCTION

SELECT.

Selection of actual signals to be displayed on the drives front panel e.g. to display conveyer

speed in feet per second based on the output frequency

Allow the user to display an alternative output unit scaled from an existing parameter. This

function is disabled if set to 0.

If parameter 3400 DISPLAY SCALING FACTOR set >0, the variable selected in parameter 3405

DISPLAY SCALING SOURCE is multiplied by the factor entered in 3400 DISPLAY SCALING

FACTOR, and displayed whilst the drive is running, with a ‘c’ to indicate the customer scaled

units.

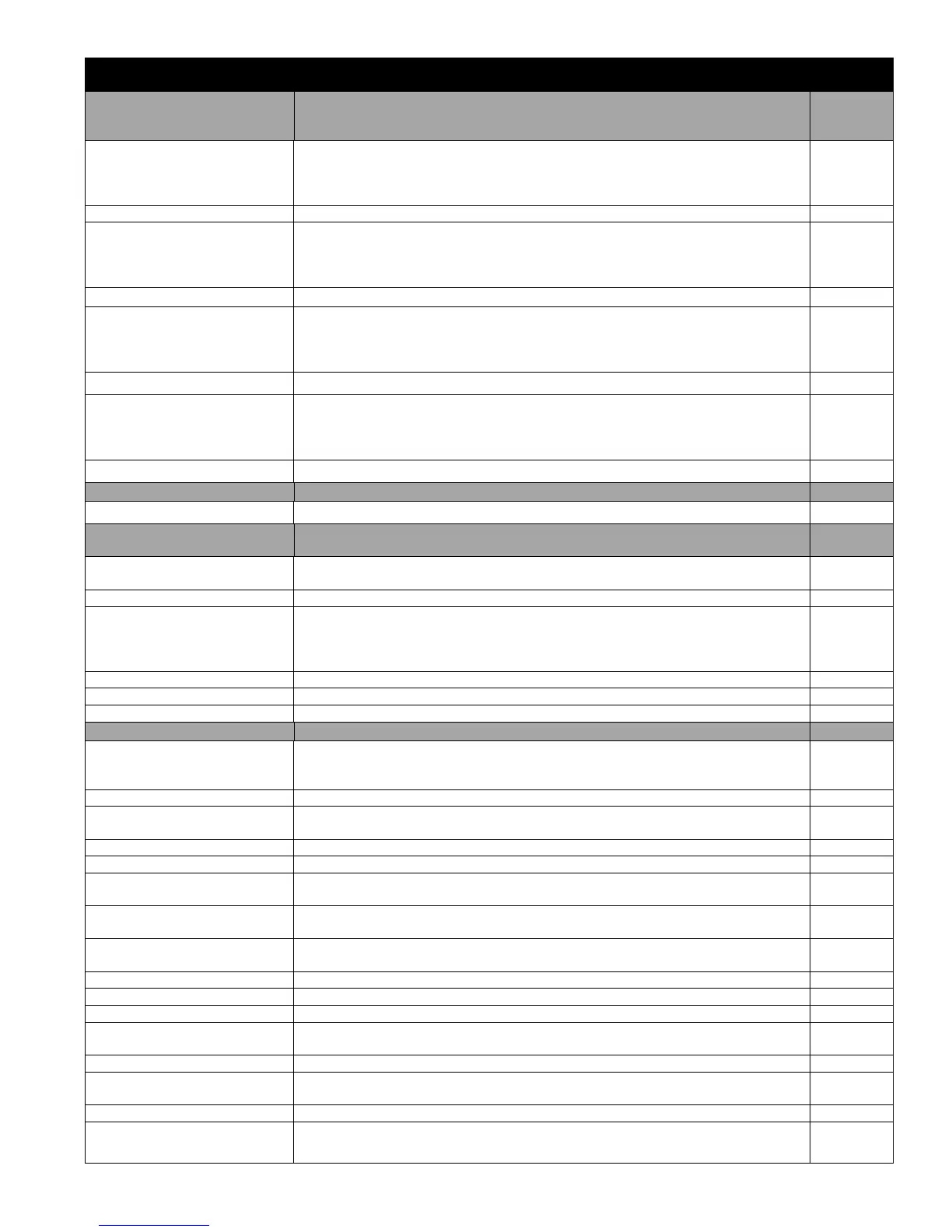

Process PI control parameter set

PI Controller Proportional Gain. Higher values provide a greater change in the drive output

frequency in response to small changes in the feedback signal. Too high a value can cause

instability

PI INTEGRAL TIME

CONSTANT

PI Controller Integral Time. Larger values provide a more damped response for systems

where the overall process responds slowly

Use this mode if an increase in the motor speed should result in an increase in the feedback

signal

Use this mode if an increase in the motor speed should result in a decrease in the feedback

signal

PI Reference (Setpoint)

Source Select

Selects the source for the PI Reference / Setpoint

Digital Preset Setpoint. Parameter 4011 PI Digital Reference (Setpoint) is used

PI Digital Reference

(Setpoint)

When parameter 4010 PI REFERENCE (SETPOINT) SOURCE SELECT = 0, this parameter sets

the preset digital reference (setpoint) used for the PI Controller

PI Feedback Signal Source

Select

Loading...

Loading...