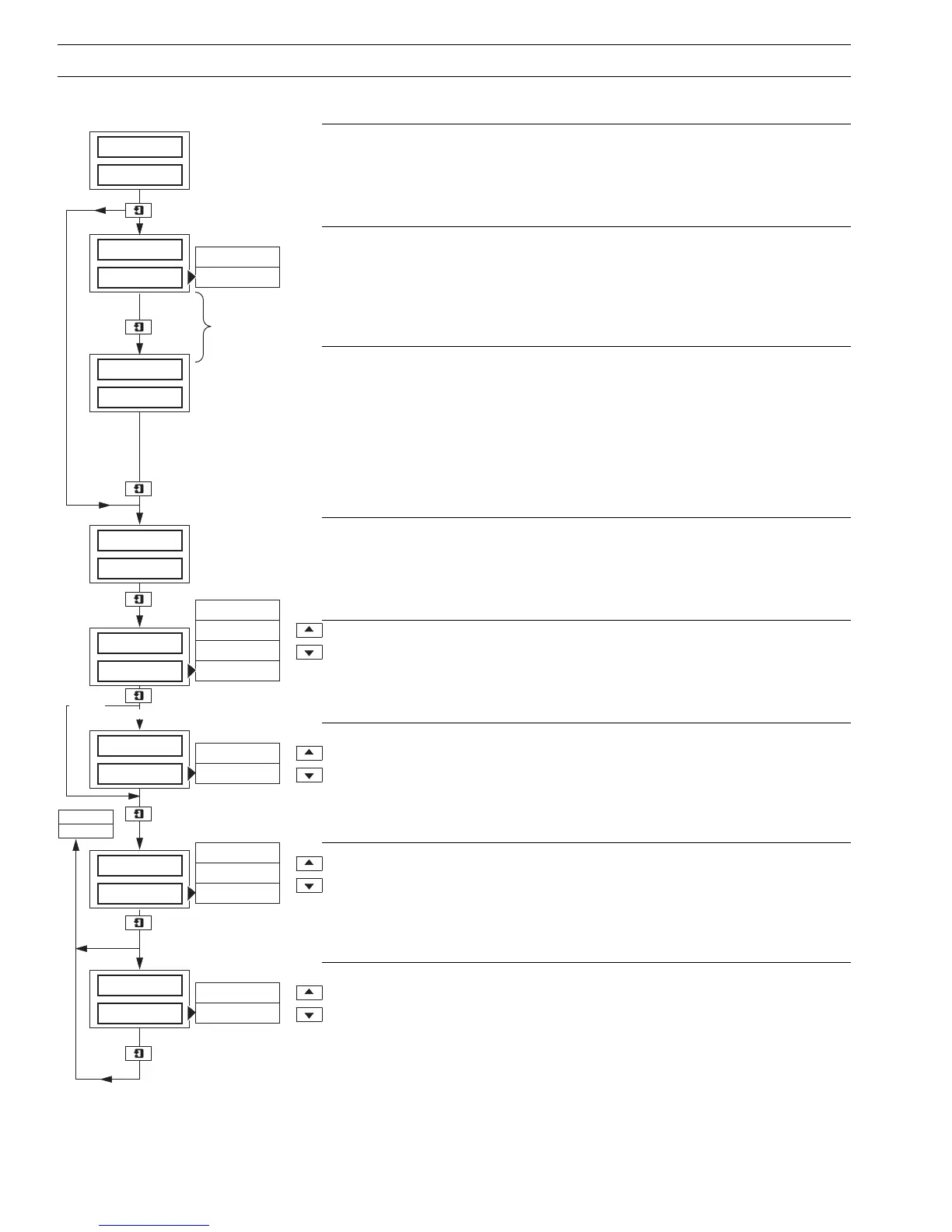

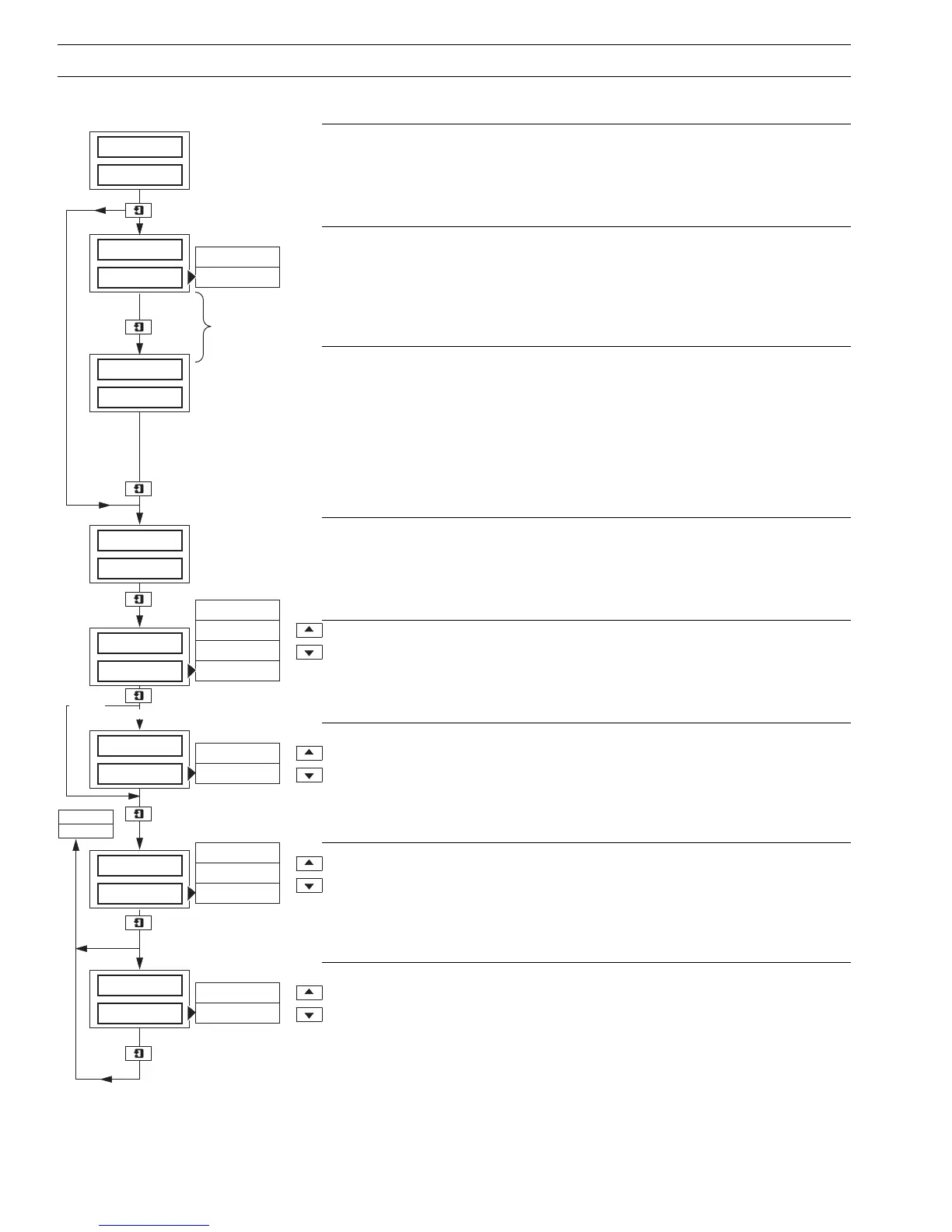

30

PAGE

CYCt

HYSt

INtGrL

dErIV

OFF

CONtrL

MrESEt

1.0

0

APPb

PrOP

___._

___._

_._

OFF

Time Proportioning

Control

only

PAGE

ContrL

1

7200

0.0

100.0

0.1

3.0

OFF

OFF

0.1

999.9

OFF

300.0

1.0

Integral Off

Derivativ

e Off

Integral

On

…5 CONTROL OPERATION

5.9.1 Control Page (Standard Control)

Page Header – Control Page

Cycle Time (applicable only for control using relay output)

This setting can be ignored for analog control outputs.

Set the required cycle time for time proportioning control, from 1.0 to 300.0 in 0.1

second increments (300 seconds = 5 minutes) – see Fig. 5.16 on page 27.

Hysteresis (applicable only for control using relay output)

This setting can be ignored for analogue control outputs.

The hysteresis is operational above or below (depending on the control action, direct

or reverse) the set point and is only applicable for ON/OFF control – see

Fig. 5.14

on page 26.

Set the hysteresis value required for on/off control in engineering units (between 0

and 10% of engineering range span).

Proportional Band

Set the proportional band value required, between 0.1 and 999.9% in 0.1%

increments.

Integral Action Time

Set the required time between 1 and 7200 in 1 second increments (7200 seconds =

120 minutes). 'OFF' is selected above 7200 or below 1.

Manual Reset

Set the required proportional band offset on the lower display, between 0.0 and

100.0% of the engineering range span in 0.1% increments.

Derivative Action Time

Set the required time between 0.1 and 999.9 in 0.1 second increments (999.9

seconds = 16.67 minutes). '

OFF' is selected below 0.1.

Approach Band

Set the required value between 0.1 and 3.0 in 0.1 increments. (Set 1.0 initially).

Loading...

Loading...