45

Faults and remedies

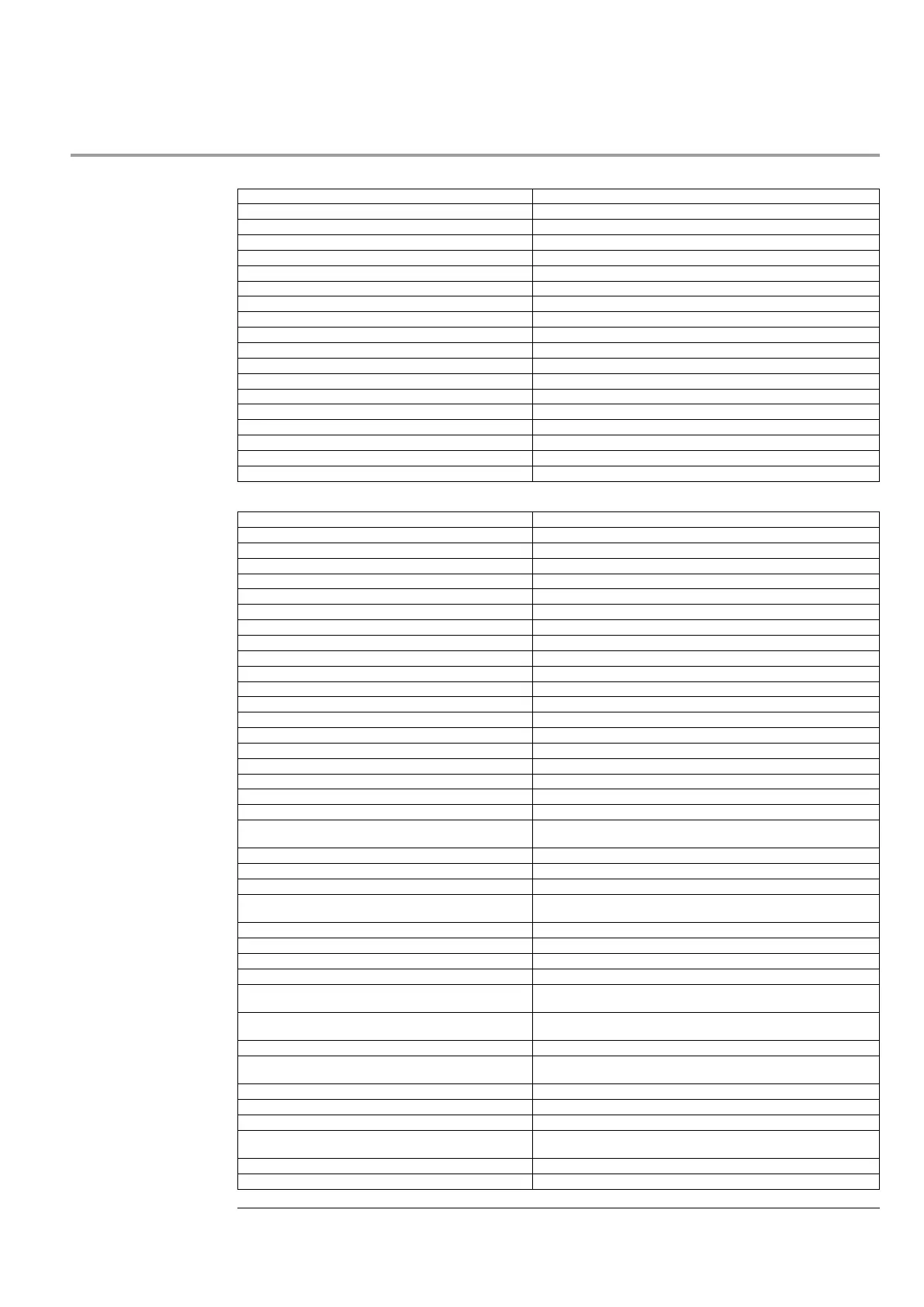

Commutation

Type of fault Causes and remedies

Brush sparking at the leading edge 1 4 8 9 10 38 39

Brush sparking at the trailing edge 1 3 22 24 37 38 39

Slight sparking 1 3 4 6 8 9 14 19 22 24 28 29 33 39

Violent sparking with showers 6 8 9 10 13 31 32 34 35 36 37 38

Arc or flash 1 10 22 26 35

Sparking of some brushes or sets of brushes 2 6 7 9 14 19 20 24 25 27 28 29 31 32 33 36 37

Burning of the rear corner of the brushes 1 4 8 14 19 27 29 30 32 35 37

Vibration and breaking of the brush edges 5 12 14 23 24 25 30 32 33 36 37

Brushes wear out too fast 6 7 8 9 12 15 16 22 23 27 30 31 32 33 37 38 39

Uneven brush wear 2 6 7 12 16 20 24 27 29 30 31 32 34 37

Plait interruptions and burning 2 6 8 10 11 16 17 18 20 23 31 35

Grooves on the brush sides 16 25

Grooves on the surfaces of contact 6 8 17

Metal particles on the surfaces of contact 14 17 20 21

Uneven commutator wear 6 11 12 15 17 18 20 23 38 39

Grooves on the commutator surface 6 12 14 15 16 17 18 20 24 27 30 33

Symmetrical stains on the commutator 1 10 13 21 28 35

Asymmetrical stains on the commutator 20 34 36 37

Scored commutator surface 6 7 12 14 16 17 19 24 27 30 38 39

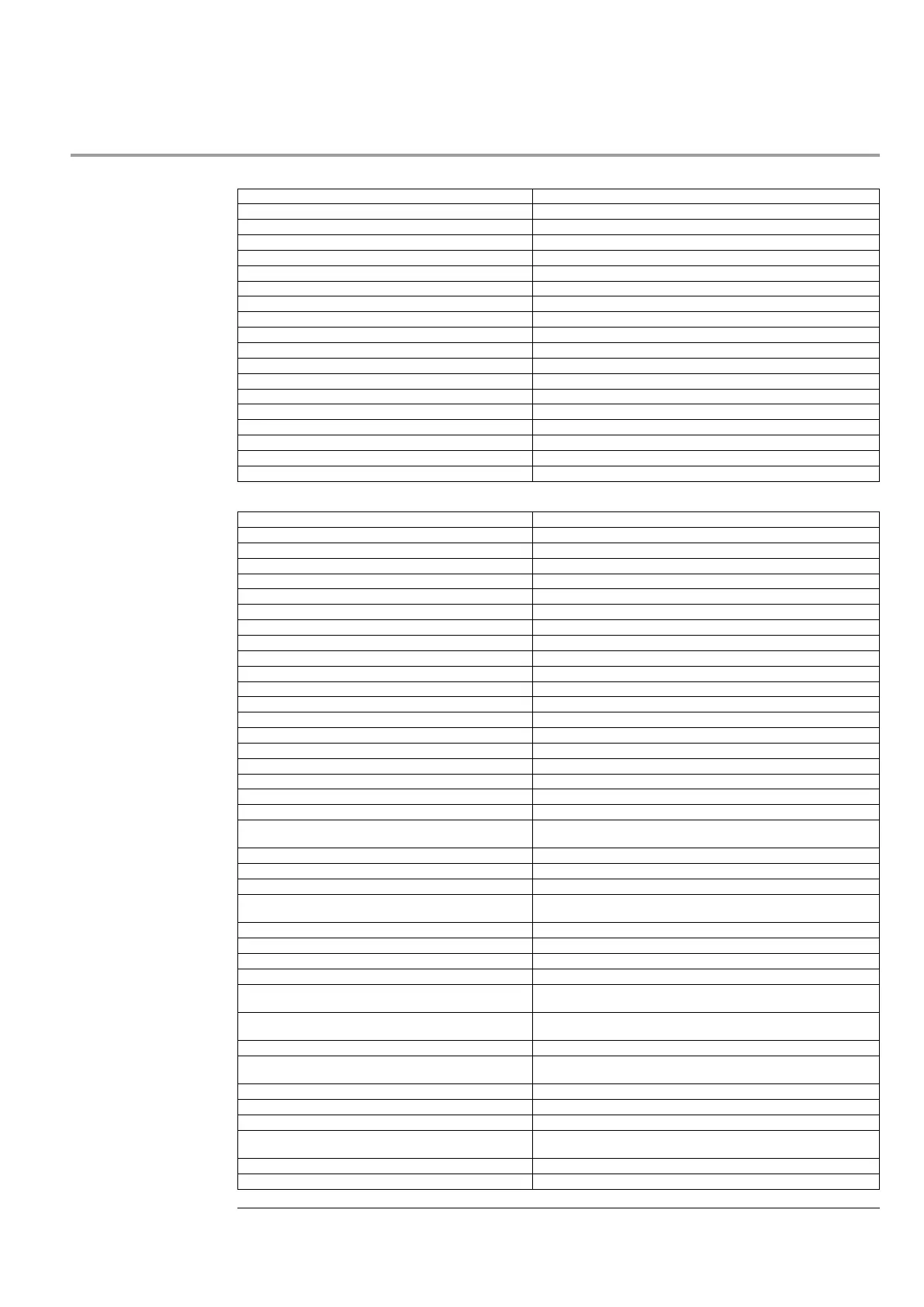

Possible cause Remedy

1) The brushes are out of neutral zone Reset neutral position

2) Asymmetry between the brush holder studs Correct the distance between the studs

3) Commutating pole flux too high Increase commutating pole air gap

4) Commutating pole flux too low Decrease commutating pole air gap

5) Excessive no load operation Use suitable brushes, reduce the number of brushes

6) Dirt and oil on the commutator Clean the commutator and identify cause

7) Abrasive dust on the brush surfaces Remove the brushes and brush them clean

8) Overload Reduce the load

9) Vibrations Check the alignment, rebalance if necessary

10) The armature winding is damaged Repair, rewind if necessary

11) Inadequate ventilation Trace the causes, then consult ABB if necessary

12) Current density at the brushes is too low Reduce the number of brushes

13) Current surges Choose suitable brush types

14) The air is too damp Let in fresh air, select suitable brushes

15) The air is too dry Let in fresh air, select suitable brushes

16) Dust or sand suspended in the air Fit filters and eliminate the causes

17) Gases or acids in the air (*) Let in fresh air, select suitable brushes

18) Excessive brush friction Reduce brush pressure, make use of non-abrasive brushes

19) Brushes not adapted to the commutator Adapt the brushes perfectly, as previously shown

20) Different brush types Use brushes of the same type

21) The commutator is stained when the

machine is not in operation

Raise the brushes

22) Brush pressure is too weak Replace the brush spring and brush presser pad

23) Excessive brush pressure Replace the brush spring and brush presser pad

24) Uneven brush pressure in different brushes Adjust pressure, replace the faulty brush springs if necessary

25) The brush holders are not perpendicular

Restore the correct distance between brush holder cases

and commutator (2 ÷ 2.5 mm)

26) The brushes are jammed in the brush holders Clean the brush holders

27) Too much play in the brush holder Change brush holder

28) Vibrations on the brush holder studs Reinforce the studs with insulating rings

29) The brush holders are not parallel Adjust brush holders

30) The brush holder case is too distant from the

commutator

Adjust distance to about 2 ÷ 2.5 mm

31) Uneven current distribution to the brushes

Increase current density; adjust pressure, make use of more

abrasive brushes

32) Mica insulator protruding from the commutator Smooth the mica insulator and the edges of the segments

33) Burrs on the commutator segments

Remove the burrs, smooth the edges, replace brushes with a

more suitable grade

34) Ovalized commutator Turn the commutator

35) Broken soldering Solder the commutator lugs

36) Scored commutator Turn the commutator

37) Protruding commutator segments

Rub the commutator with a pumice stone, turn the

commutator if necessary

38) No choke coil where needed Connect the choke coil

39) Choke coil reactance different from specified one Replace the choke coil

(*) Harmful gases which may be present in the air: sulphates, silicones, chlorine, ammonia. consult ABB in these cases

Loading...

Loading...