Specifications

42/18-84-EN TZIDC, TZIDC-110, TZIDC-120 41

9.1.5 Transmission data and influences

Output Y1

Increasing Increasing setpoint signal 0 ... 100 %

Increasing pressure at output

Decreasing Increasing setpoint signal 0 ... 100 %

Decreasing pressure at output

Action (setpoint signal)

Increasing Signal 4 ... 20 mA = actuator position 0 ... 100 %

Decreasing Signal 20 ... 4 mA = actuator position 0 ... 100 %

Characteristic curve (travel = f {setpoint signal})

Linear, equal percentage 1:25 or 1:50 or 25:1 or 50:1 and freely

configurable with 20 reference points.

Deviation <

0,5 %

Tolerance band 0.3 ... 10 %, adjustable

Dead band 0.1 ... 10 %, adjustable

Resolution (A/D conversion) > 16000 steps

Sample rate 20 ms

Influence of ambient temperature <

0.5 % per 10 K

Influence of vibration <

1 % to 10 g and 80 Hz

Seismic vibration

Meets requirements of DIN / IEC 68-3-3 Class III for strong and

strongest earthquakes.

Influence of mounting orientation

Not measurable.

Complies with the following directives

- EMC Directive 2004/108/EC as of December 2004

- EC Directive for CE conformity marking

Communication

- HART Protocol 5.9

- Local connector for LKS (not in Ex area)

- HART communication via 20 mA signal line with (optional) FSK

modem

9.1.6 Environmental capabilities

Ambient temperature

For operation, storage and transport: -40 … 85 °C (-40 ... 185 °F)

When using proximity switches

SJ2-S1N (NO):

-25 … 85 °C (-13 ... 185 °F)

Relative humidity

Operational (with closed housing

and air supply switched on):

95 % (annual average),

condensation permissible

Transport and storage: 75 % (annual average), non-

condensing

9.1.7 Housing

Material / Degree of protection

Aluminum, protection class IP 65 (optional IP 66) / NEMA 4X

Surface / Color

Electrostatic dipping varnish with epoxy resin, stove-hardened.

Case varnished black, RAL 9005, matte, housing cover Pantone

420.

Electrical connections

Screw terminals:

Max. 1.0 mm

2

(AWG 17) for options

Max. 2.5 mm

2

(AWG 14) for

4 ... 20 mA input signal

IMPORTANT (NOTE)

Do not expose the terminals to strain.

Four thread combinations for cable entry and pneumatic

connection

- Cable: thread 1/2-14NPT, air pipe: thread 1/4-18 NPT

- Cable: thread M20 x 1,5, air pipe: thread 1/4-18 NPT

- Cable: thread M20 x 1,5, air pipe: thread G 1/4

- Cable: thread G 1/2, air pipe: thread Rc 1/4

(Optional: With cable gland(s) and pipe plugs if necessary)

Weight

1,7 kg (3,75 lb)

Mounting orientation

Any

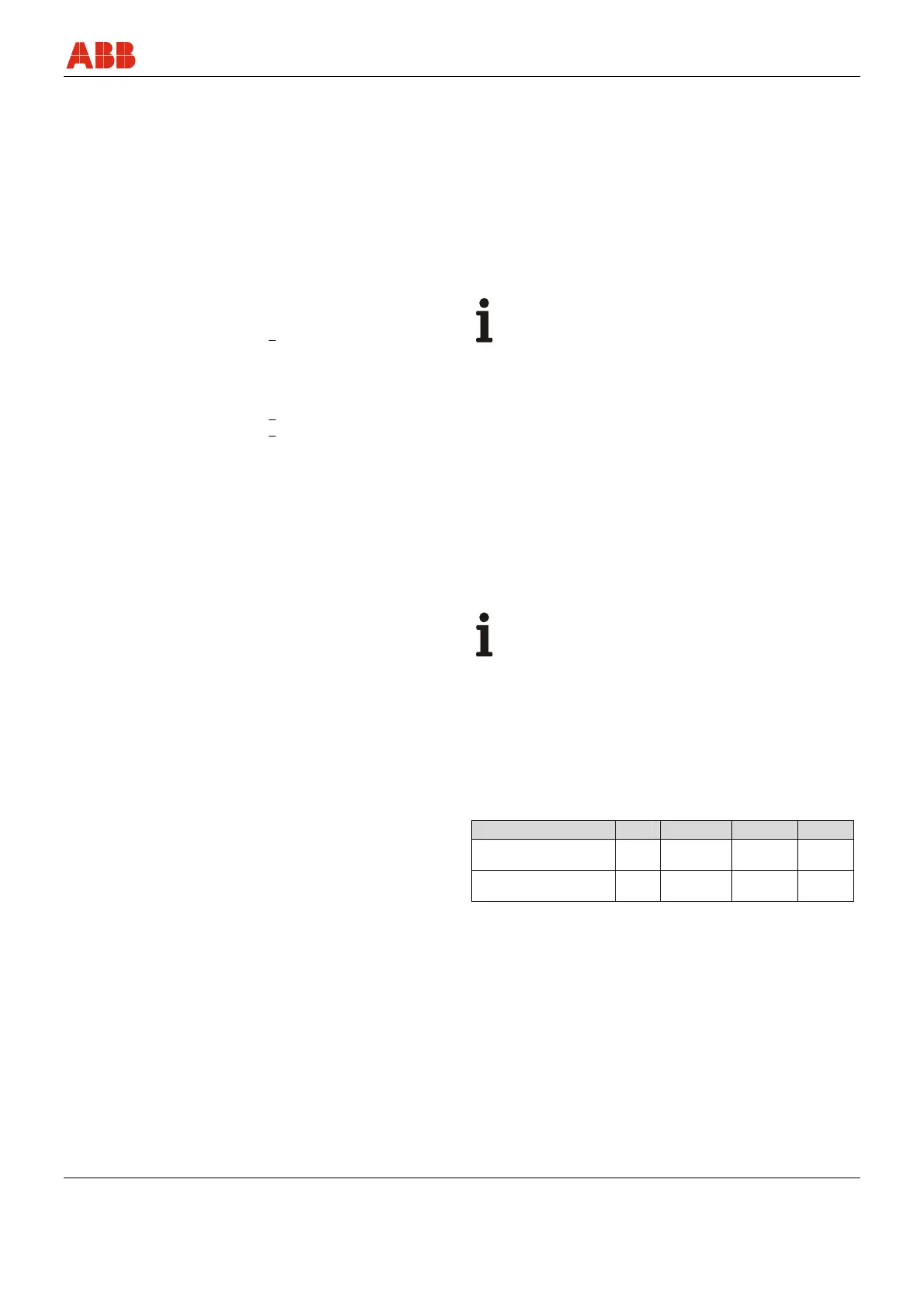

9.1.8 Safety Integrity Level

IMPORTANT (NOTE)

Applies to applications with single-acting and depressurizing

pneumatics.

The positioner TZIDC / TZIDC-200 and the emergency shutdown

module for meet the requirements regarding:

- functional safety acc. to IEC 61508

- explosion protection (depending on the model)

- electromagnetic compatibility in accordance with EN 61000

Without the input signal, the pneumatic module in the positioner vents

the drive and the installed spring in it moves the valve in a

predetermined end position (OPEN or CLOSED).

SIL specific safety-related characteristics:

Device SFF PFDav

λ

dd

+ λ

s

λ

du

TZIDC / TZIDC-200 as

shutdown module

94 %

1.76 * 10

-4

718 FIT 40 FIT

TZIDC / TZIDC-200 with

supply current 0 mA

94 %

1.76 * 10

-4

651 FIT 40 FIT

For details refer to the Management Summary in the SIL-Safety

Instructions 37/18-79XA.

Loading...

Loading...