32 UNIGEAR ZS2 INSTALLATION, OPERATION AND MAINTAINANCE INSTRUCTION MANUAL

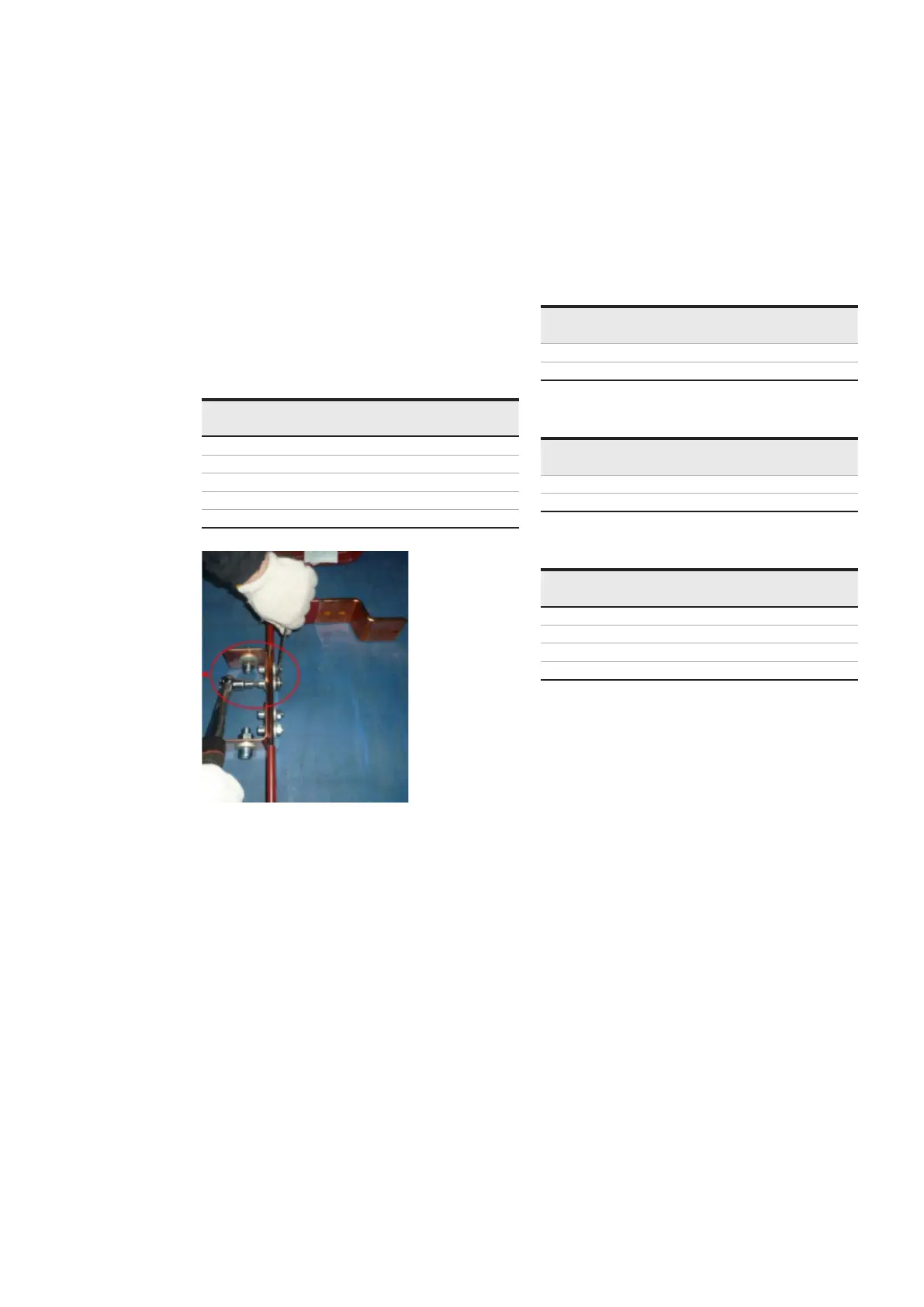

Use screws of tensile class 8.8. The maximum

recommended tightening torques based on each

type of connection are given in the following

tables:

1. Tightening torques for copper/Aluminium

bars or combined Flat Busbar connections.

Thread (2)

Max. recommended tightening

torque Nm (1)

M5(3) 2.5

M6(3) 10

M8 25

M10 50

M12 85

2. Tight. Torques for copper/Aluminium bar

connections combined with CTs.

Thread (2)

Max. recommended tightening

torque Nm (1)

M12 70

M10 50

3. Tight. Torques combined with Insulating parts

(Epoxy resin, BMC, SMC, ABS, PC etc.)

Thread (2)

Max. recommended tightening

torque Nm (1)

M8 15

M10 32

4. Tightening torques for Fixed Contacts inside

bushing and Insulator supports

Thread (2)

Max. recommended tightening

torque Nm (1)

M8 25

M10 50

M12 85

M20 220

—

6. Assembly of the switchgear panels

Loading...

Loading...