34 UNIGEAR ZS2 INSTALLATION, OPERATION AND MAINTAINANCE INSTRUCTION MANUAL

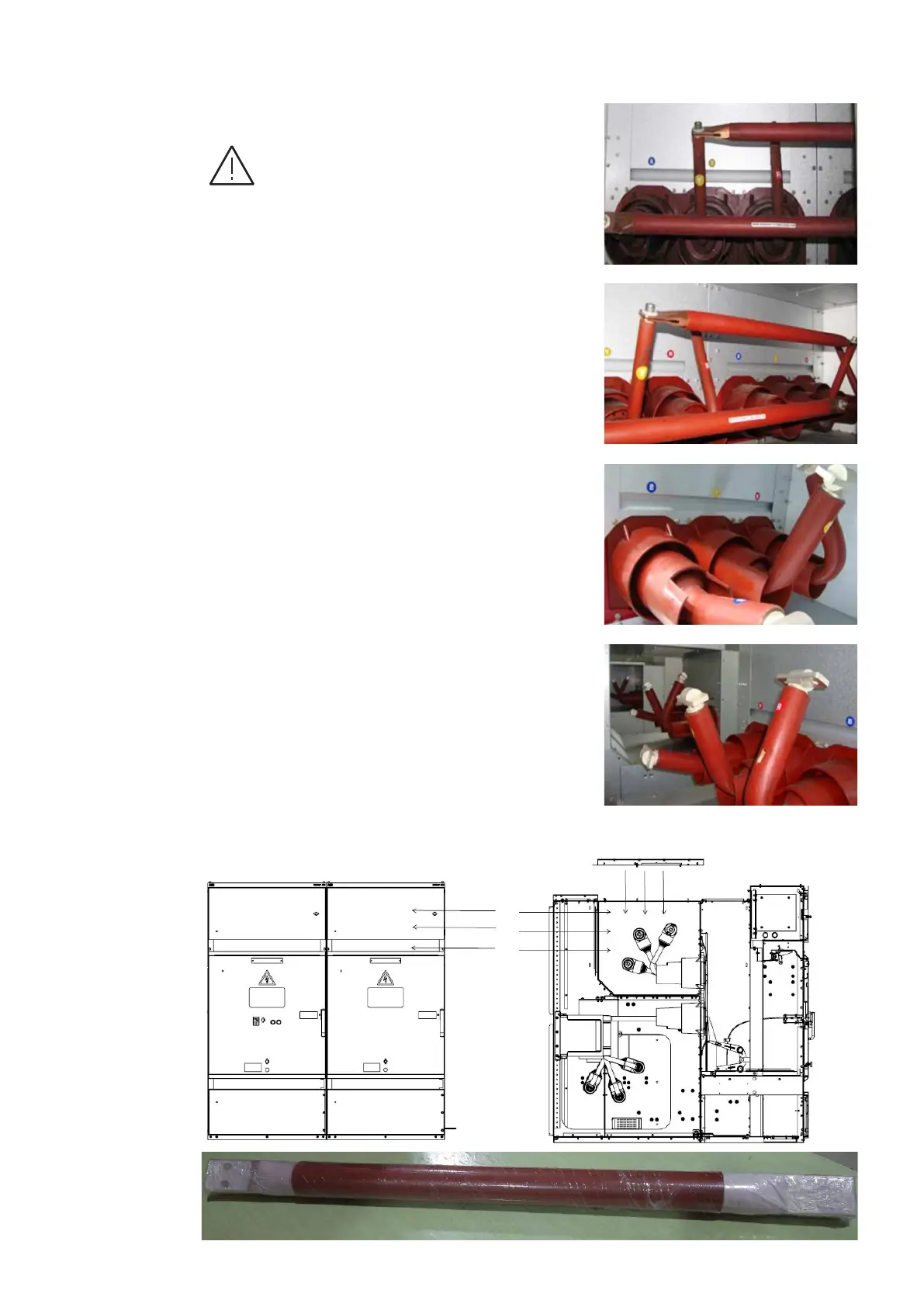

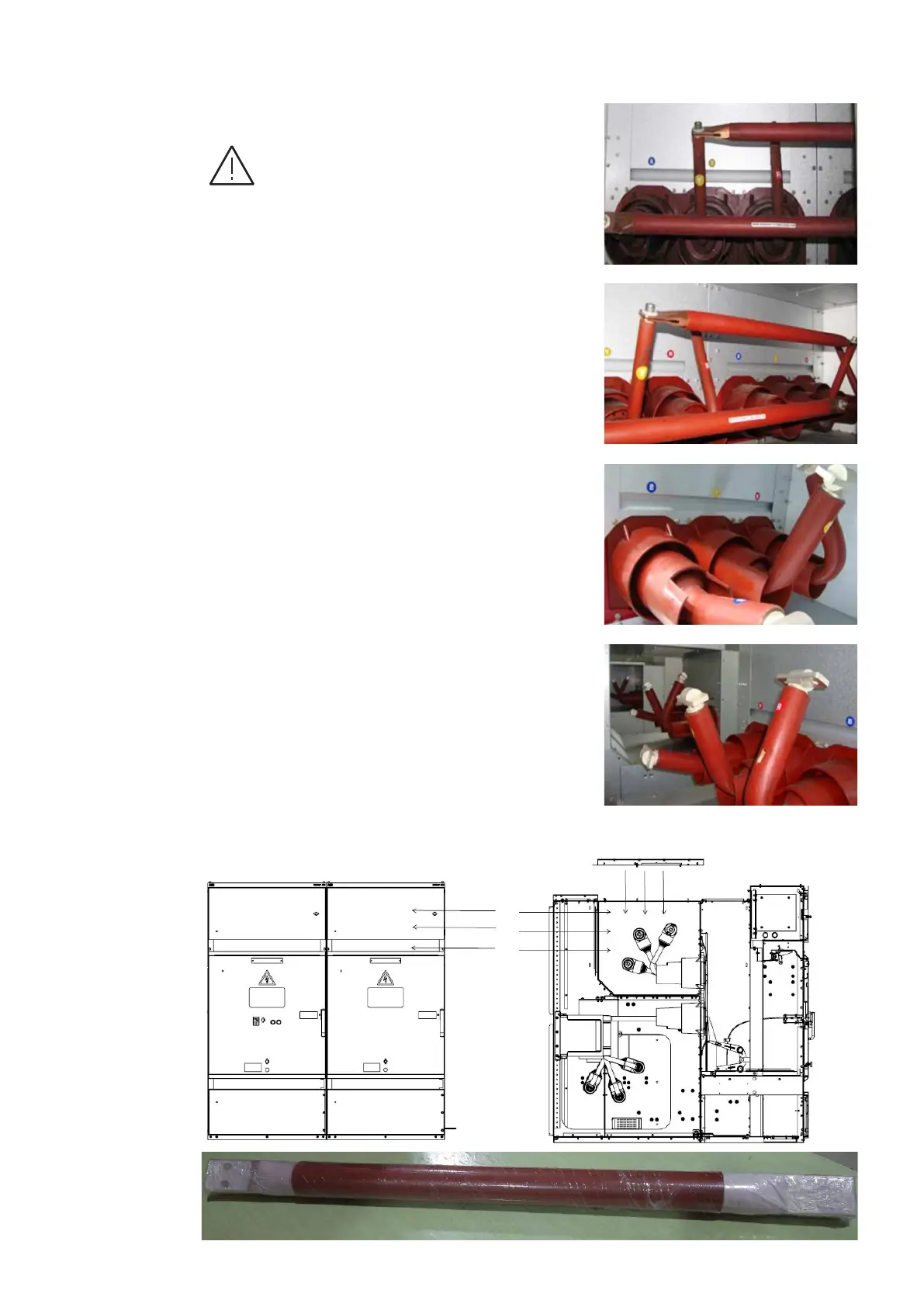

6.1 Installation of busbars

CAUTION

Use proper personal protective equipment like

hand gloves, helmets, safety shoes, etc. while

handling switchgears. Accesses for the main

busbars installation are from sides and from

top of the UniGear ZS2 switchgear.

It is recommended to carry out busbar assembly

along with erection of individual switchgear;

utilizing the advantage offered by access from

sides of the main busbar compartment.

Insulated main busbars and droppers, and

shrouds are delivered as loose items.

Care shall be taken to protect the insulation

against damage during storage and handling.

When opted for insulated busbars, damaged

insulation shall be renewed. An air cushion type

PVC protective covering will protect the insulated

parts from damage during transportation and

installation. It is recommended to keep them

wrapped on busbars as long as possible, until

commissioning. Busbar assembly work calls

for cleanness as the dielectric strength will be

detrimentally affected by foreign objects like

metal dust, loose threads and oil patches.

Ensure that contact surfaces of busbars and

connector parts are clean. Use only the strong

type of conical spring-washers (ABB standard

9ADA334, DIN 6796) for all bolted connections.

This will help maintain required contact pressure

of the switchgear and minimizes the risk of

problem due to overheating. Torque meter

shall be used during erection, Recommended

tightening torques are as tabulated in Table 5.

Loading...

Loading...