PowerFlex 700 Technical Data

72 20B-TD001F-EN-P

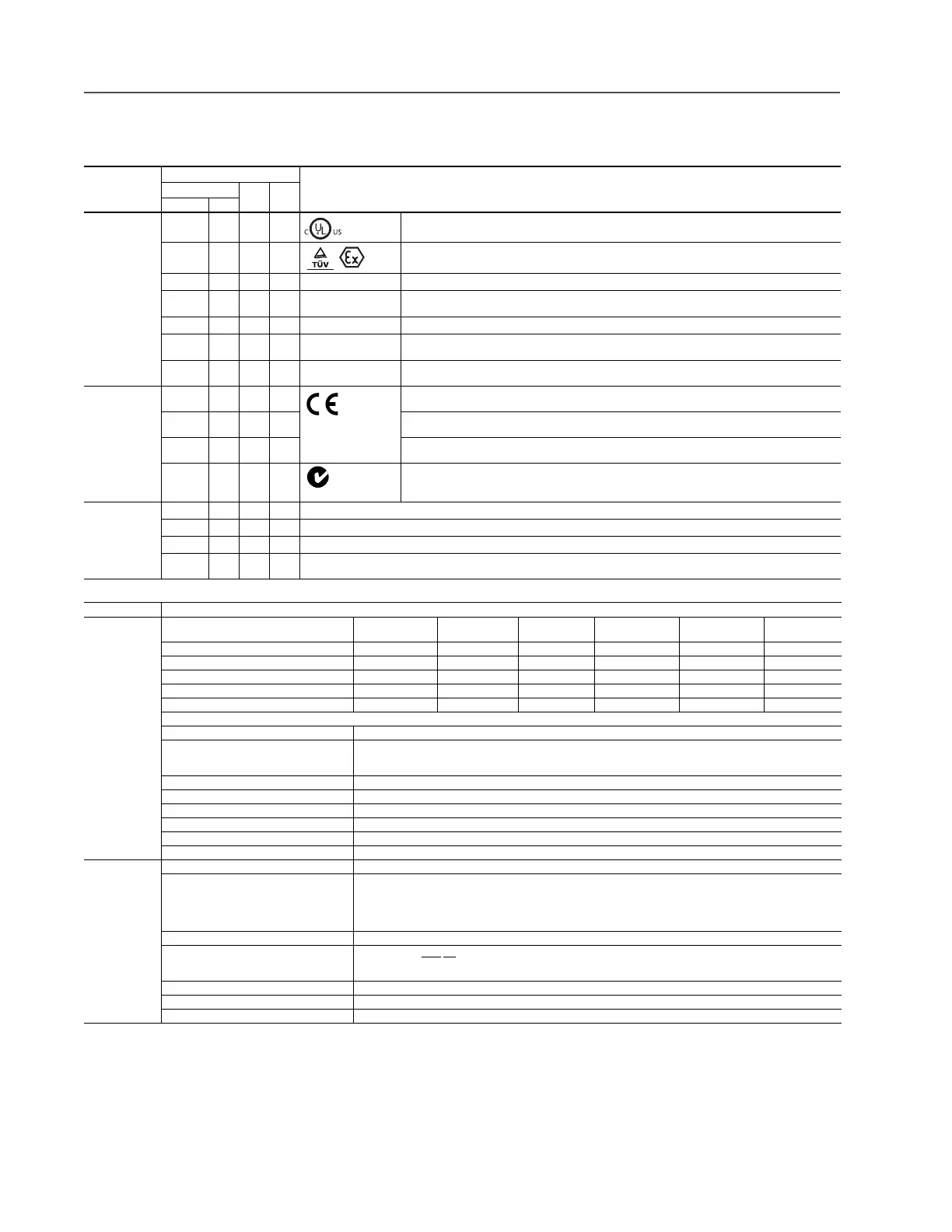

Specifications

Control and Performance

Category

Frames

Specification

0…4

5…6 7…10

230…480V 600V

Agency Listings,

Certification or

Tests

✔✔✔✔

Listed to UL508C and CAN/CSA-C22.2 No. 14-05.

Packaged drives may be listed to UL508A

✔✔✔✔

EC-Type-Examination Certificate TUV 05 ATEX 7153 for directive 94/9/EC: Safe turn off of certified ATEX motors used

in Group II Category (2) GD potentially explosive atmospheres.

✔✔

EPRI /SEMIF47 EPRI Quality Star Certificates SEMIF47.115 and SEMIF47.127 for SEMI F47 compliance, 480V units tested

✔✔

ABS

American Bureau of Shipping MA Certificate 08-HS303172B/1-PDA for auxiliary services on AB Classed

vessels and offshore platforms

✔✔

LLoyd’s Register Lloyd’s Register Type Approval Certificate 08 / 60015 (marine certification)

✔✔✔

RINA RINA Type Approval Certificate ELE283205CS (Registo Italiano Navale - marine certification)

✔✔✔

Trentec Tested by Trentec to be compliant with AC156 Acceptance Criteria for Seismic Qualification Testing of Nonstructural

Components and 2003 International Building Code for worst-case seismic level for USA excluding site class F

Rockwell

Automation

Certifications

Certified by Rockwell Automation to be in conformity with the essential requirements of the applicable European

Directives and the standards referenced below have been applied:

✔✔✔✔

2006/95/EC (Low Voltage Directive)

EN 50178 Electronic Equipment for use in Power Installations

✔✔✔

2004/108/EC (EMC Directive)

EN 61800-3 Adjustable Speed electrical power drive systems - Part 3: EMC requirements and specific test methods.

✔✔✔

Certified by Rockwell Automation to be in conformity with the requirements of the applicable Australian legislation and

the standards referenced below:

IEC 61800-3

Designed to Meet

Applicable

Requirements

✔✔✔✔

CMAA Specification #70 (Crane Manufacturers of America Association)

✔✔✔✔

NFPA 70 - US National Electrical Code

✔✔✔✔

NEMA ICS 7.1 - Safety Standards for Construction and Guide for Selection, Installation, and Operation of Adjustable Speed Drive Systems

✔✔✔✔

IEC 61800-2 Adjustable Speed Electrical Power Drive Systems - Part 2: General Requirements - Rating specifications for low voltage adjustable

frequency AC power drive systems.

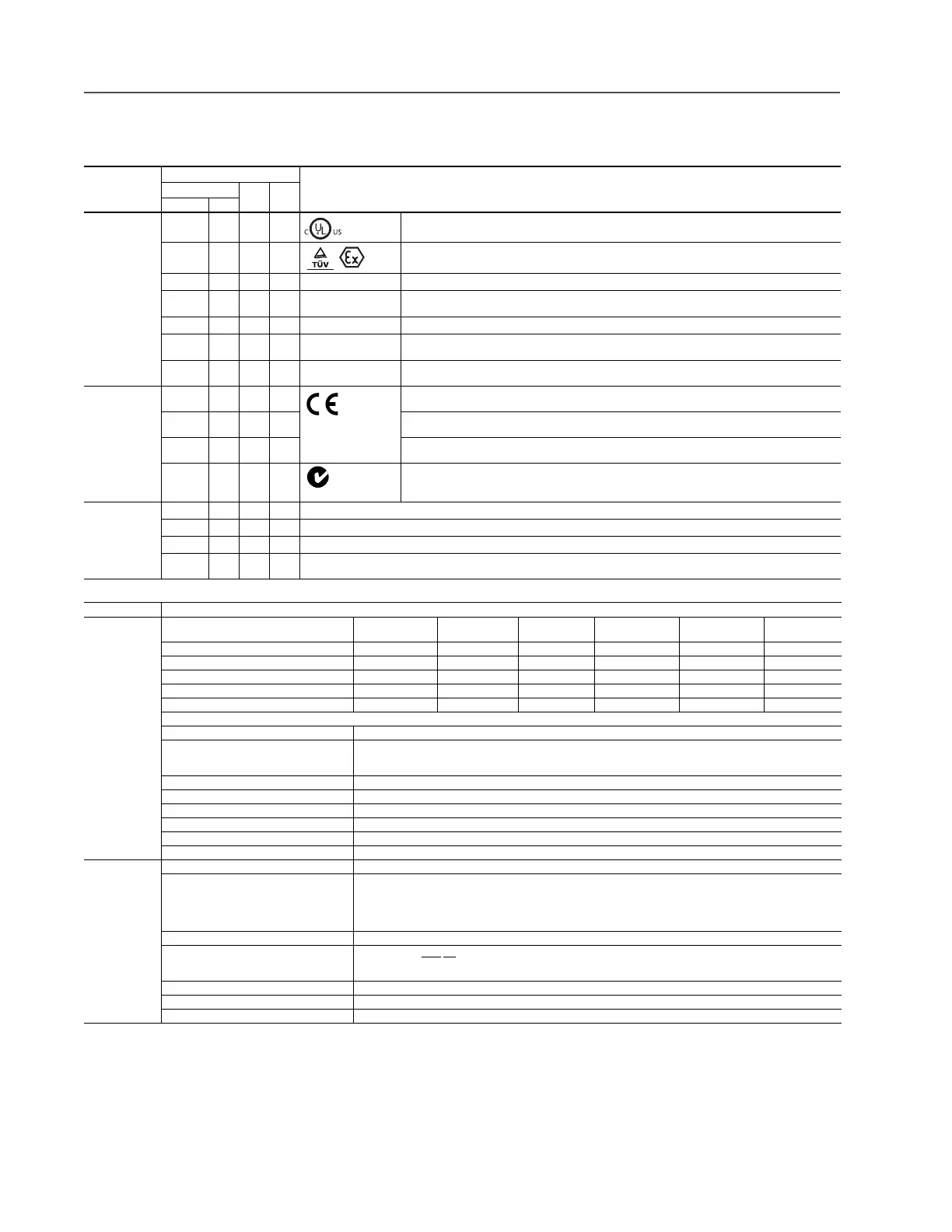

Category Specification

Protection Drive 200-

208V

240V 380/400V 480V 600V

Frames 0…4

600/690V

Frames 5…6

AC Input Overvoltage Trip: 285VAC 285VAC 570VAC 570VAC 716VAC 818VAC

AC Input Undervoltage Trip: 120VAC 138VAC 233VAC 280VAC 345VAC 345VAC

Bus Overvoltage Trip: 405VDC 405VDC 810VDC 810VDC 1013VDC 1162VDC

Bus Undervoltage Shutoff/Fault: 153VDC 153VDC 305VDC 305VDC 381VDC 437V DC

Nominal Bus Voltage: 281VDC 324VDC 540VDC 648VDC 810VDC 932VDC

All Drives

Heat Sink Thermistor: Monitored by microprocessor overtemp trip

Drive Overcurrent Trip

Software Overcurrent Trip:

Hardware Overcurrent Trip:

200% of rated current (typical)

220…300% of rated current (dependent on drive rating)

Line transients: up to 6000 volts peak per IEEE C62.41-1991

Control Logic Noise Immunity: Showering arc transients up to 1500V peak

Power Ride-Thru: 15 milliseconds at full load

Logic Control Ride-Thru: 0.5 seconds minimum, 2 seconds typical

Ground Fault Trip: Phase-to-ground on drive output

Short Circuit Trip: Phase-to-phase on drive output

Environment Altitude: 1000 m (3300 ft) max. without derating

Maximum Surrounding Air Temperature without

Derating - IP20, NEMA/UL Type Open:

Frames 0…6

Frames 7…10

0 to 50 degrees C (32 to 122 degrees F), typical. See pages 33 through 36 for exceptions.

0 to 40 degrees C (32 to 104 degrees F) for chassis (heatsink)

0 to 65 degrees C (32 to 149 degrees F) for control (front of backplane)

Storage Temperature (all const.): –40 to 70 degrees C (–40 to 158 degrees F)

Atmosphere: Important: Drive must

not be installed in an area where the ambient atmosphere contains volatile or corrosive gas, vapors or dust.

If the drive is not going to be installed for a period of time, it must be stored in an area where it will not be exposed to a corrosive

atmosphere.

Relative Humidity: 5 to 95% non-condensing

Shock: 15G peak for 11ms duration (±1.0 ms)

Vibration: 0.152 mm (0.006 in.) displacement, 1G peak

II (2) G D

N223

Loading...

Loading...