-

-

-

I

I

I

N

N

N

S

S

S

T

T

T

R

R

R

U

U

U

C

C

C

T

T

T

I

I

I

O

O

O

N

N

N

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

-

-

-

5

MACHINE LOADING

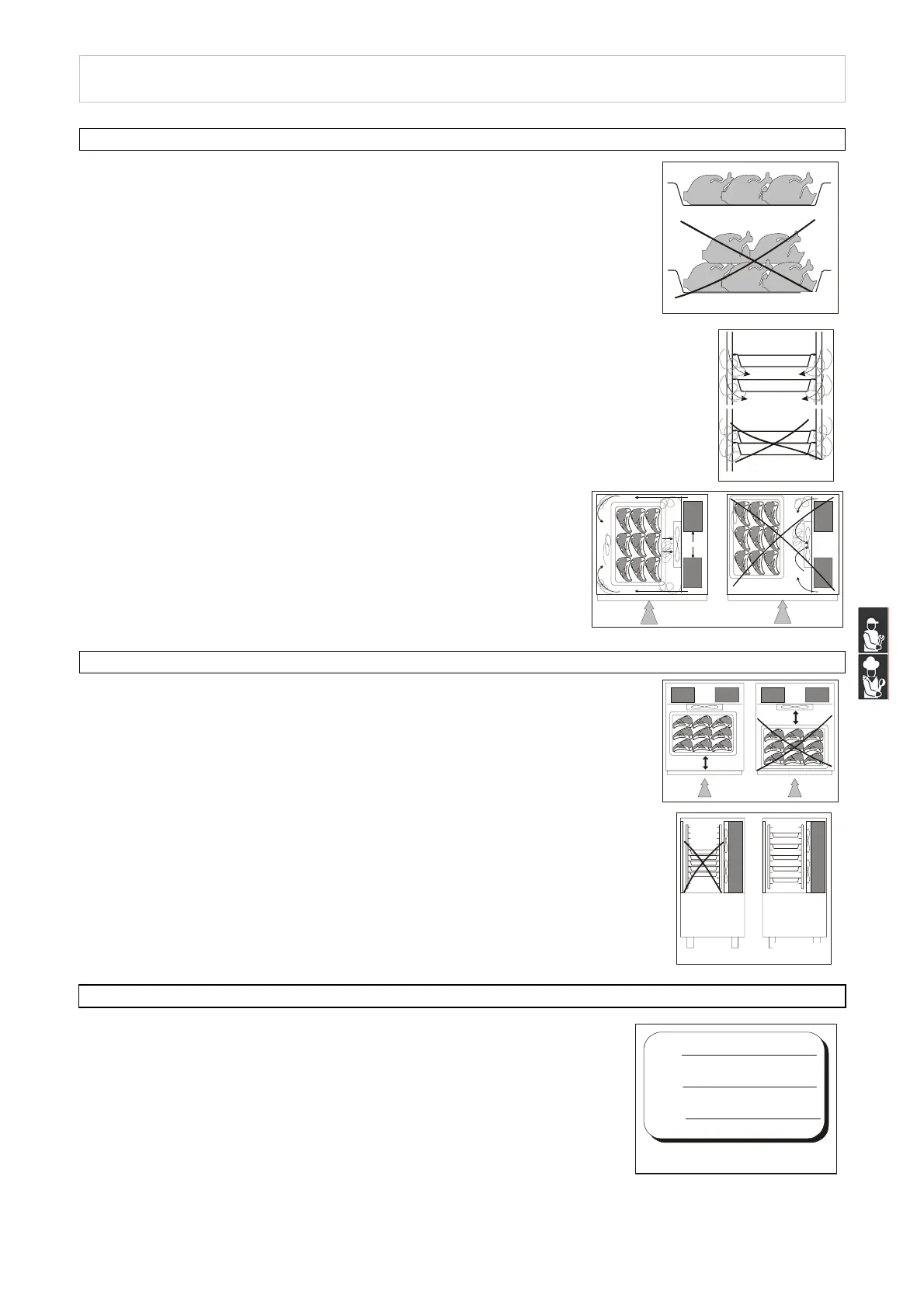

Do not pile up foodstuffs to be cooled. Thickness should be lower than 50 mm] in

negative quick cooling and lower than 80[mm] in positive quick cooling. (pict.1)

Make sure air circulation is not hampered between food trays. (pict.2)

The grid-holding frame (included in those models which include

trolleys) is to be located at the centre of the cabinet. (pict.3)

POSITION OF TRAYS

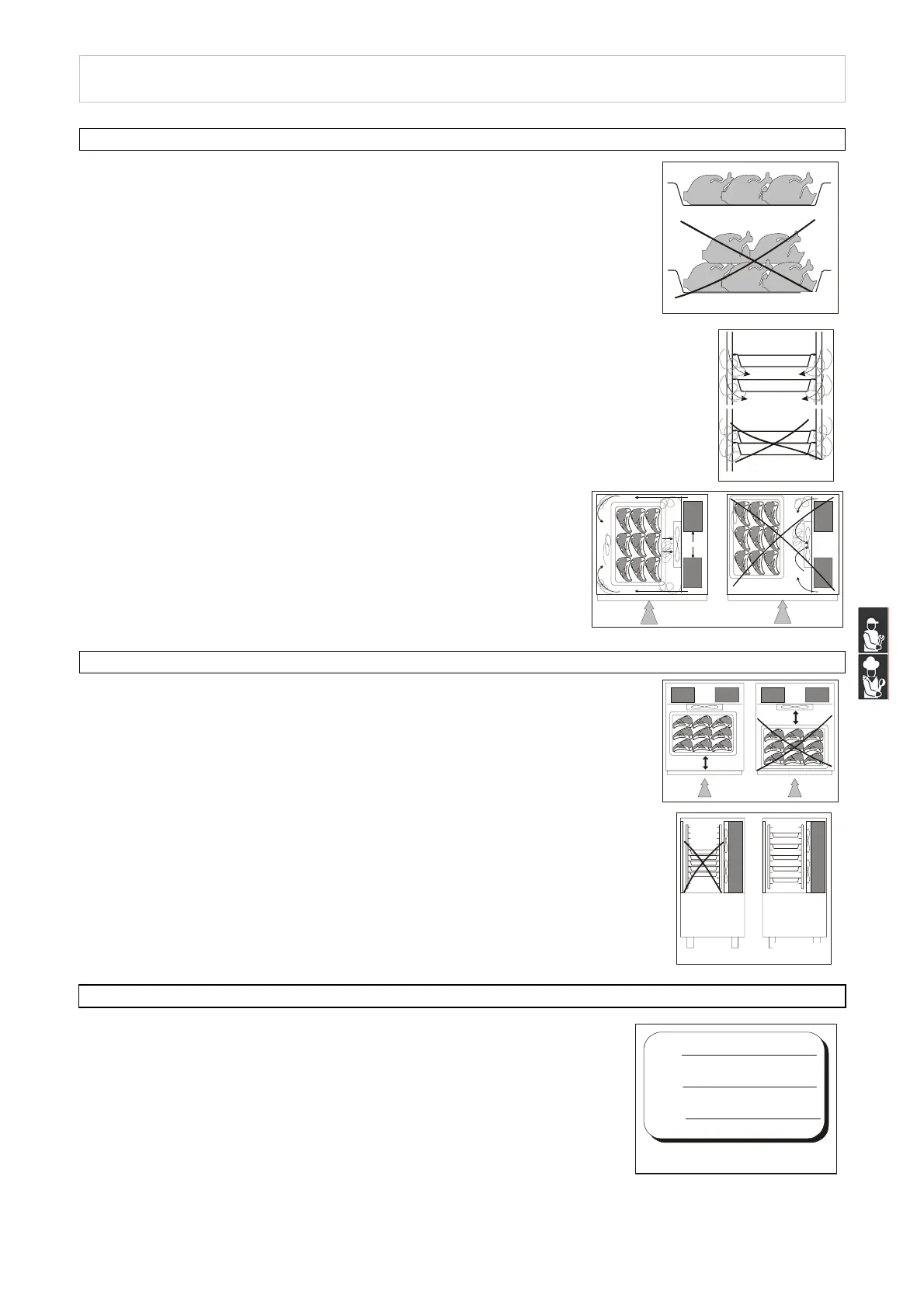

Place the trays as close to the evaporator as possible. (pict.4)

If the cabinet is not full place the trays at equal distance from one another. (pict.5)

LENGTH

Cooled or frozen processed foodstuffs may be stored in a refrigerator for 5

days of processing with no quality alterations.

For best results we recommend keeping temperature constant throughout the

storing (0°C to 4°C), according to the various commodities.

Storing time may be increased to approx. two weeks by using vacuum

processing.

After a negative quick cooling cycle, foodstuffs may be stored safely for 3 to 18

months, according to the type of foodstuff processed.

We strongly recommend keeping storing temperature at -20°C or below.

A

B

C

0.5 - 2 cm.

Pict.1

Pict.2

Pict.3

Pict.4

Pict.5

Pict.6

Loading...

Loading...