Installation & Servicing instructions ATAG A-Series

36

13.1 Checking the O

2

and CO/CO

2

The O

2

percentage is set in the factory. This has to be checked during

inspection, maintenance and in case of a failure.

This can be veried by means of the following action:

- Set the external controls to call for heat;

- Make sure the boiler is operational and can get rid of the heat it produces;

- Calibrate the O

2

gauge;

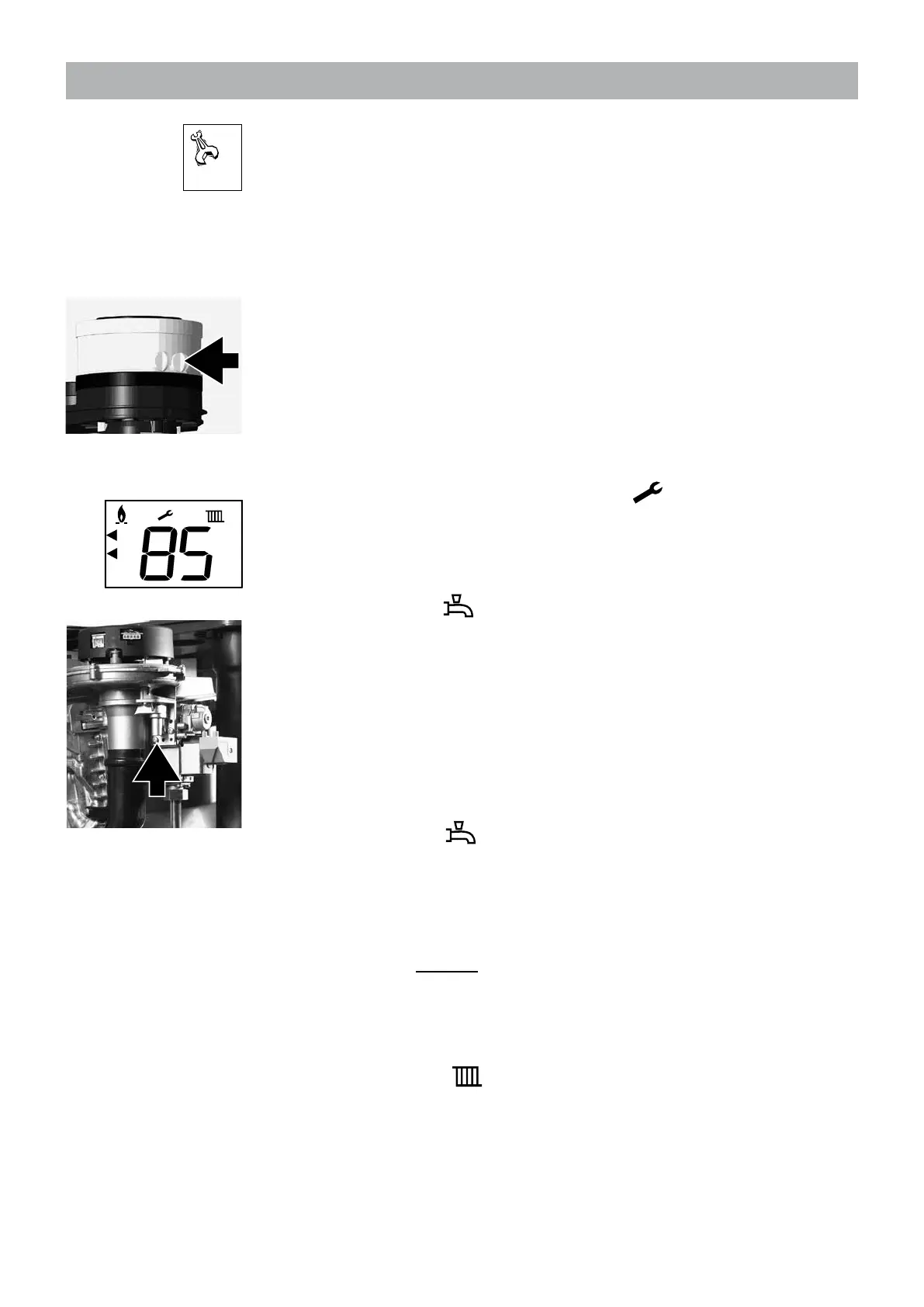

- Place the lance of the O

2

gauge into the ue gas test point (see Figure 13.1.a);

- Press both + buttons for 6 seconds;

- When the ame symbol appears in the display press both + buttons again for 6 se-

conds;

- The display shows the supply water temperature (

appears in the display);

The boiler will switch to 50% of the heating capacity

- Press 1x the i button;

the display shows 50% (heating capacity)

- Press on the + button (

) until the maximum value (100%) has been reached;

- Leave measuring O

2

to the measuring equipment.

Natural gas Propane

- O

2

percentage at full load = 4,7% (+/-0,2%) 5,1% (+/-0,2%)

- CO/CO

2

ratio less than 0.004%

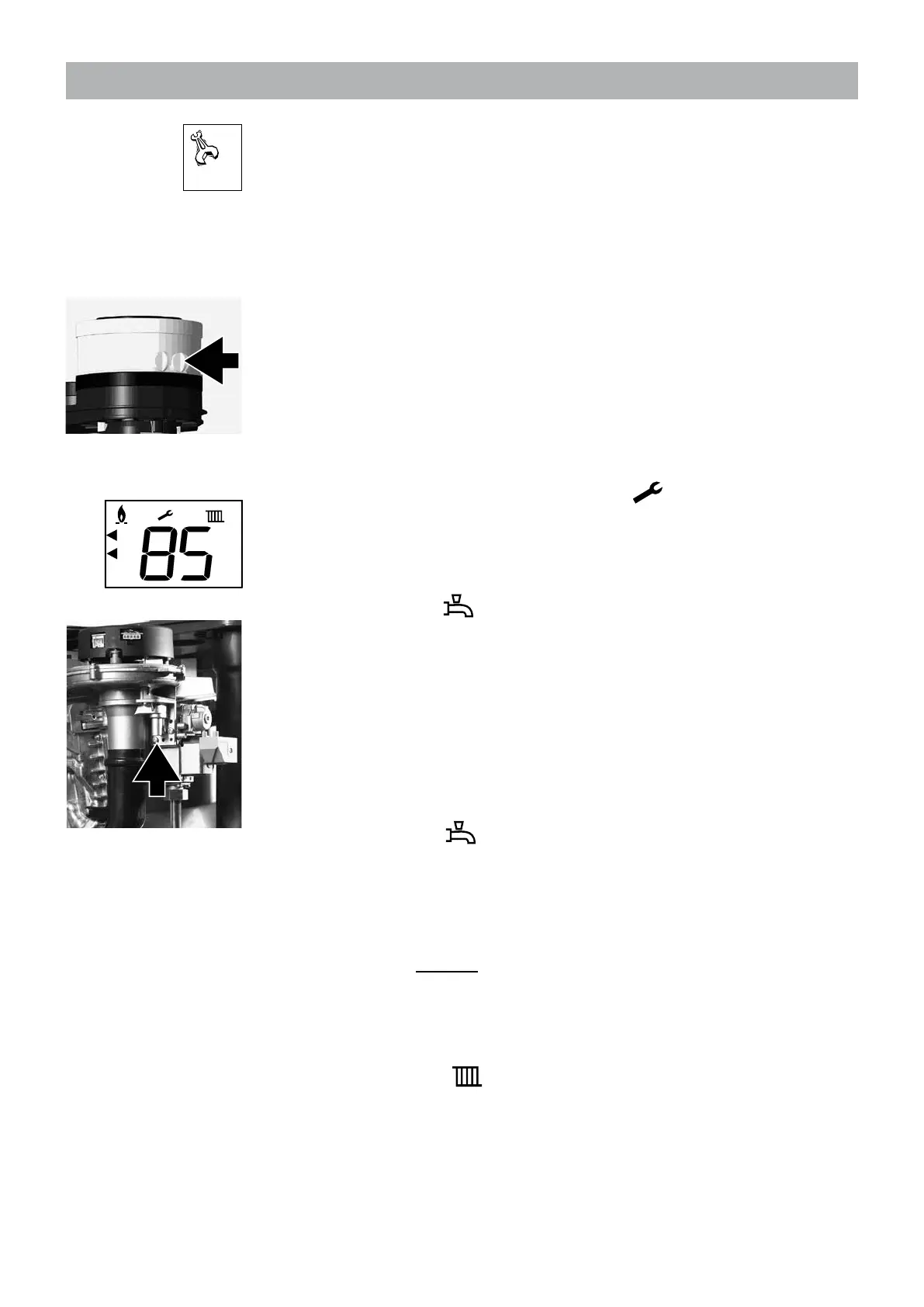

- If required, you may turn the setting screw to set the correct O

2

percentage.

(refer to Figure 13.1.b).

Finally, the O

2

percentage at low load must be checked:

- Press on the - button (

) until the minimum value (0%) has been reached (low

load)

- Leave measuring O

2

to the measuring equipment and check if the measured O

2

percentage on low load is between following values:

Natural gas Propane

- O

2

percentage at low load between 5,0% and 7,0% 5,1% and 7,0%

- CO/CO

2

ratio less than 0.004%

Contact ATAG Heating when the measured values is outside this range.

End of measuring:

- Press the ESC button (

button).

The device switches off.

The display shows for 2 seconds C1 80 or C1 81.

This completes the procedure.

Measuring point O

2

Figure 13.1.a

Adjustment screw O

2

Figure 13.1.b

Loading...

Loading...