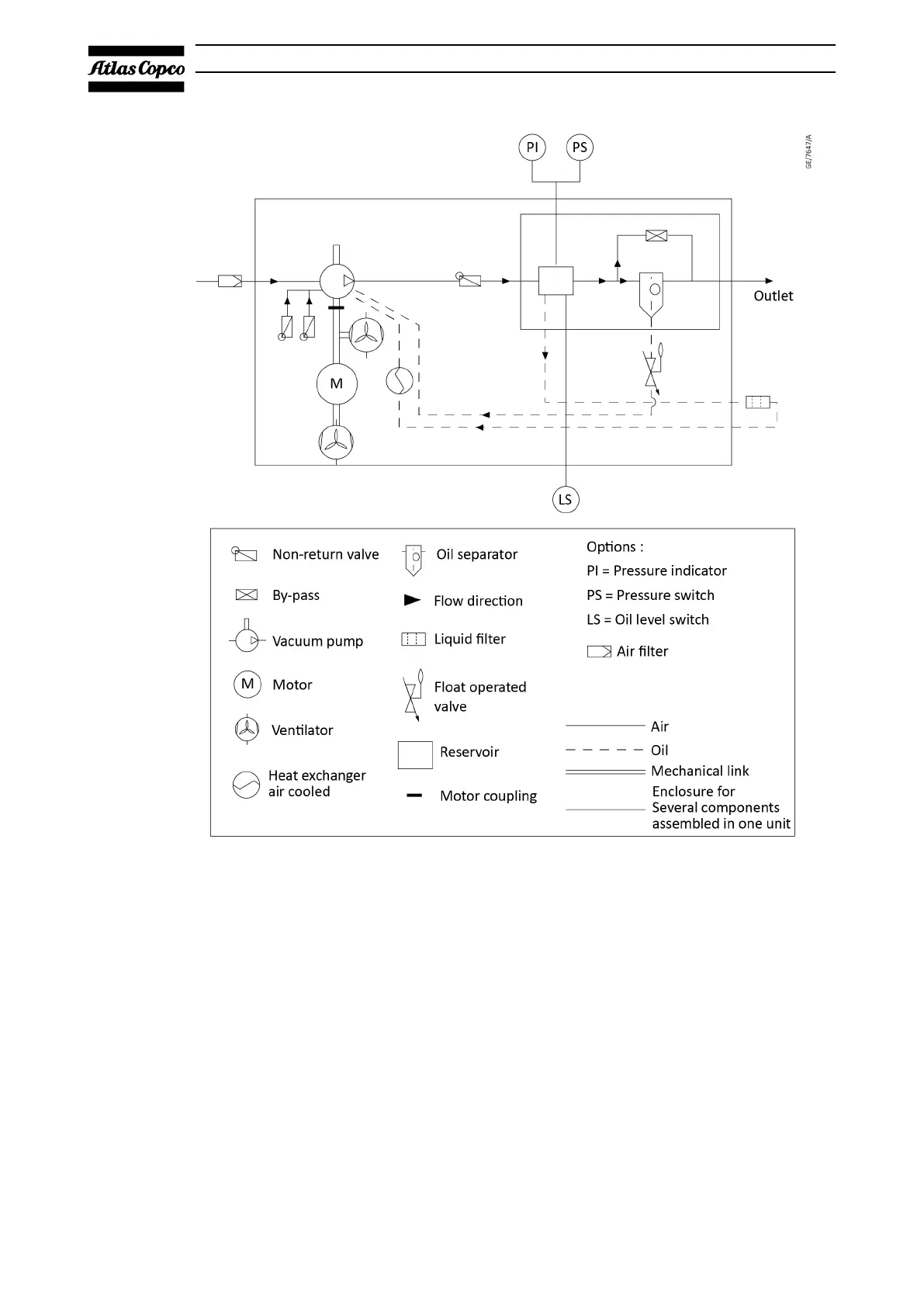

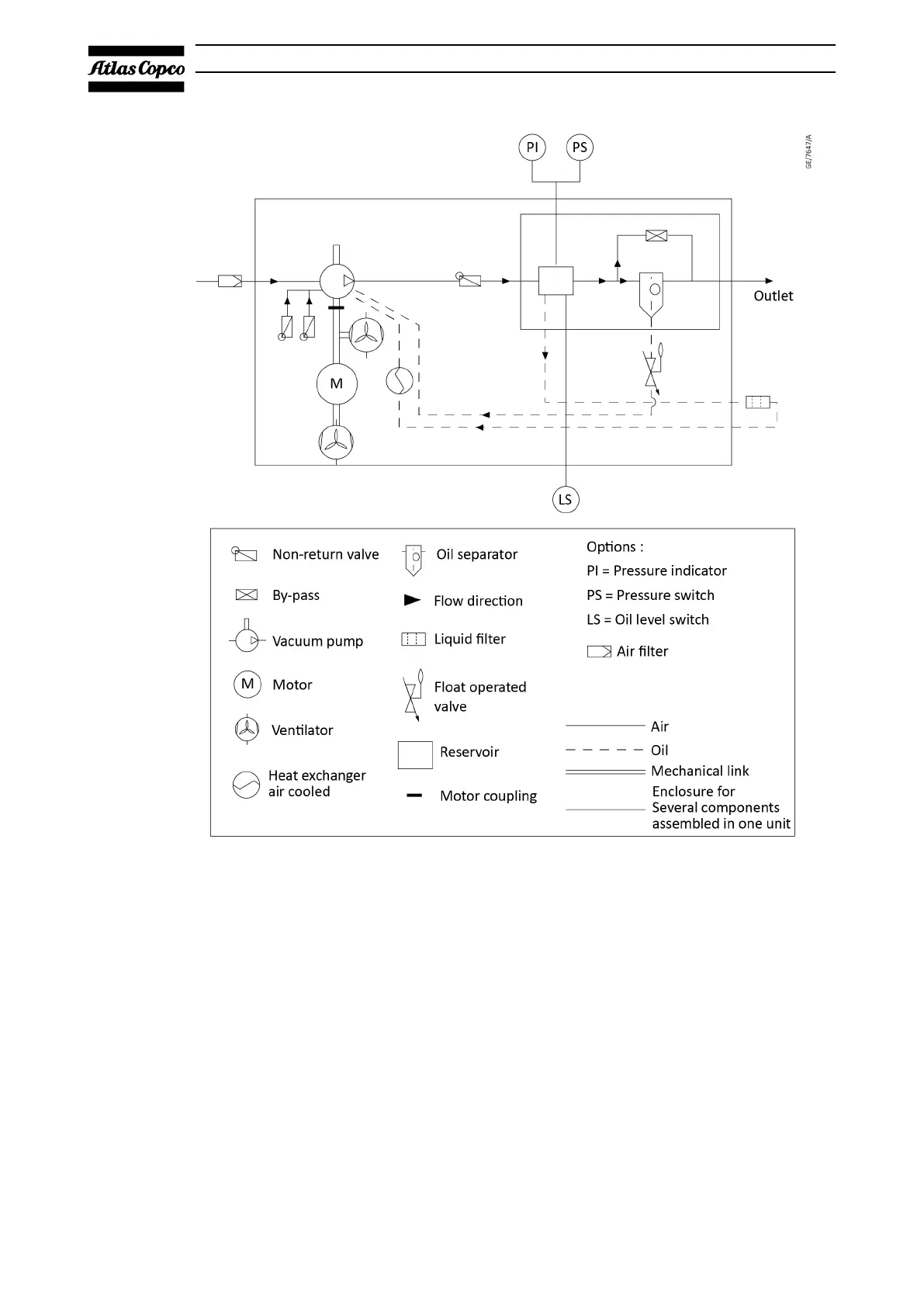

Figure 9 Flow diagram - GVS 470A and GVS 630A

3.4. Oil flow

Oil injected into the pump chamber serves to seal, lubricate and cool the pump.

The oil entrained with the compressed gas is coarsely trapped in the bottom part

of the oil casing. Oil is finely filtered in the integrated exhaust filter elements. The

proportion of oil in the exhaust gas is reduced below the visibility threshold (over

99 % entrapment rate). The oil trapped in the exhaust filters is returned to the

generator via an oil return line. To prevent the entry of gas, flowing at

atmospheric pressure from the oil reservoir, into the intake port the oil return line

is controlled by a float valve. The oil cycle is maintained by the pressure

difference between the oil casing (pressure above atmospheric pressure) and the

intake port (pressure below atmospheric pressure).

12/2021 - ©Atlas CopcoPage 236996022430_C

Description

Loading...

Loading...