20 21

TIGHTENING STRATEGIES

Select tightening strategy by choosing the method for applying clamping

force (or preload) to the joint. Different joints require different strategies for

applying the desired clamping force and to minimize unwanted in-service

effects.

The Turbo Tight

®

strategy enables the option to use Manual programming or

Quick prog, see section Strategy. The Quick step, Two step, and Three step

strategies enable the choice of tightening towards a Target torque or a Target

angle value, see section Target.

All tightening strategies require that you set either Target torque or Target

angle value.

Turbo Tight

®

Tightening Strategy

Turbo Tight

®

is the default tightening strategy, designed to perform a very

fast and ergonomic tightening based on the tool’s maximum speed (Tool

max speed). This strategy only requires Target torque to be set in order to

perform the tightening. Depending on the joint properties, for example if the

joint is very stiff or very soft, a different tightening strategy might be needed.

Note! The Turbo Tight

®

strategy is only available when using the Tensor STR

tools.

Fine-tuning the Turbo Tight

®

Tightening strategy

If the Turbo Tight

®

strategy gives unwanted results, we recommend you to

take look at how the Rundown complete is set.

A Rundown complete set too high could give the Turbo Tight

®

strategy too

little time to work on the needed calculations in the Tightening step, and

result in an overshoot. The ambition should be to set the Rundown complete

as close to snug as possible. A Rundown speed set too high could also cause

the Turbo Tight

®

not to have enough time to work on the needed calculations

in the Tightening step resulting in an overshoot. This is even more important

if the joint is very stiff.

Reduced cycle times

Turbo Tight

®

optimizes the tightening speed to achieve the fastest possible

tightening maintaining reliable accuracy. The results are:

• Possibility to remove bottlenecks,

• Possibility to rebalance assembly lines due to increased

cycle rate,

• Less heat development, a cooler tool during operation.

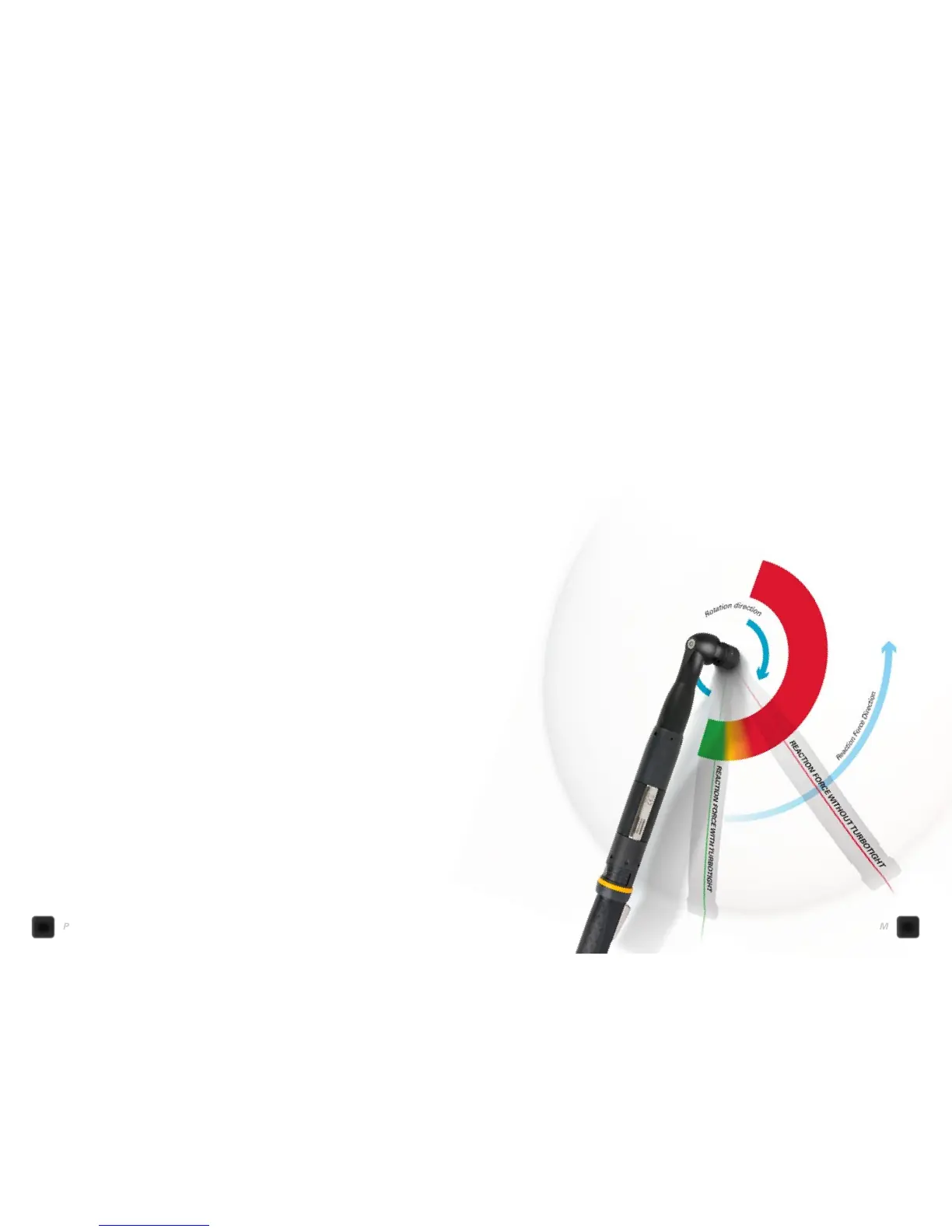

Reduced reaction force

With optimized tightening speed, the torque builds up faster,

reducing the amount of force transmitted to the operator’s hand.

The results are:

• Reduced operator fatigue and risk of injury,

• Improved operator comfort during tightening,

Reduced need for reaction absorbing devices in certain situations, giving

less cost and reduced tool weight.

Easy set-up

Turbo Tight

®

is designed to be extremely easy to set up. In most cases, you

just need to set the target torque and you’re ready to go. Exceptions are

discussed in the following chapters. In such cases please contact your local

Atlas Copco Tools representative for support. The results are:

• Time savings during set-up,

• Less time and money spent on training,

Work rotation enabled.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

21

Loading...

Loading...