32 33

STR TOOL

Overview

Tensor STR tools can be powered by the Power Focus 4000 and the Power

Focus 6000 controllers. The full capacity of the tool is available when

controlled by the Power Focus 6000.

When running on a Power Focus 4000:

• Tools are generally running on a slightly lower max

speed around 90% of maximum.

• Turbo Tight

®

is not available when running on a

Power Focus 4000.

• When connecting the ETT tool to a Power Focus

4000 the front trigger can only be programmed to

act as a safety trigger.

• When connecting STR tools to Power Focus 4000

the ST tool cable should be used.

The tool has been designed for a very high level of reliability and durability.

Heat transfer has been improved a lot compared to previous generations.

The heat is more efficiently transferred over the tool, keeping the hot areas

cooler. This increases the life length of grease and in the long run the

internal mechanical parts. IP54 classification (ETV and ETD) is another factor

that highly contributes to the increased durability, since the tool is better

sealed and protected for intrusion of dust and fluids.

ETV and ETD are the full featured STR tools. ETT is missing the IP

classification and gyroscope. ETP is of an older base design but offers the

same level of connectivity and accuracy as the most recent tools.

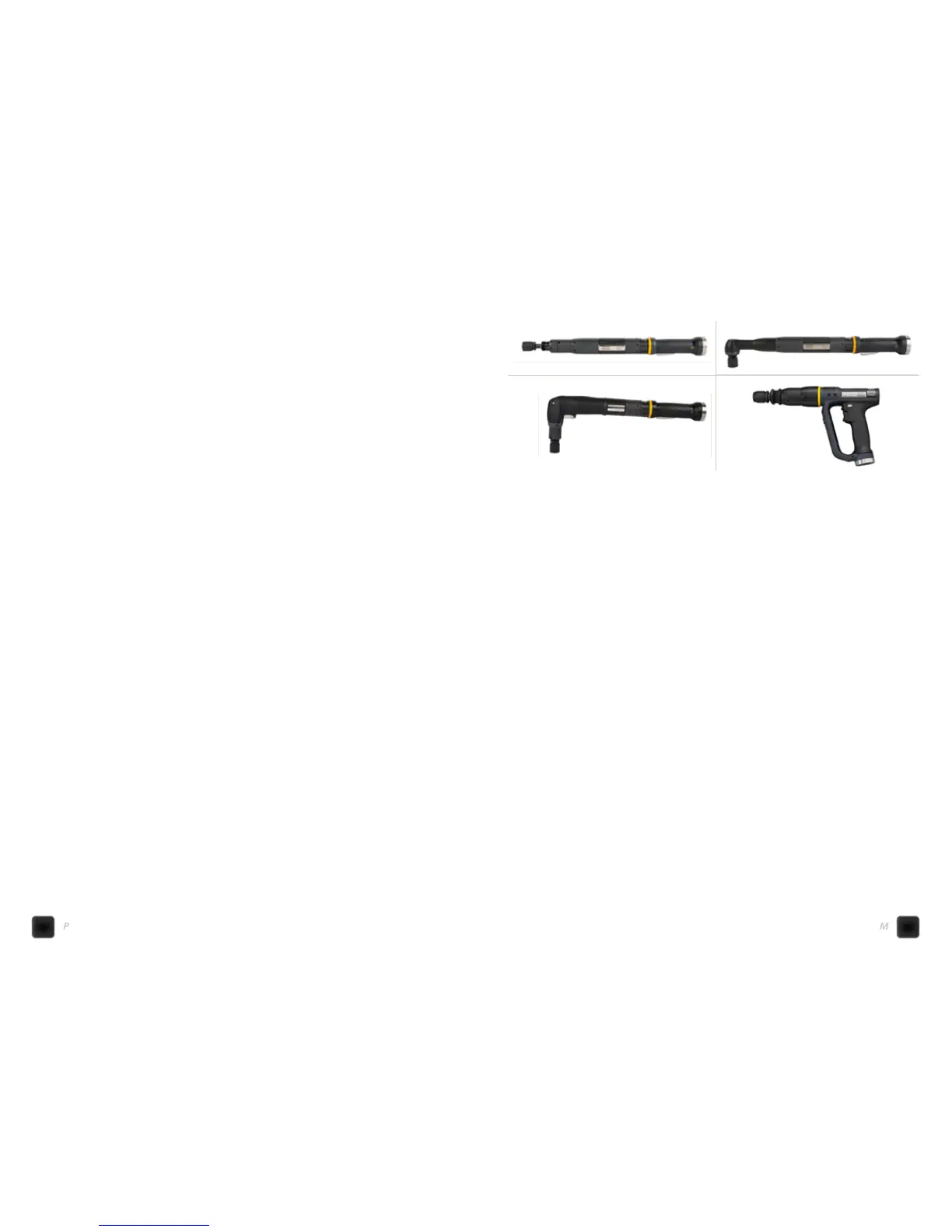

Models

Tool Modules

The STR concept uses modules to increase quality and flexibility. Different

modules are combined with new models and all the motors have the same

diameter so modules can be interchangeable between different sizes.

Due to matching electronics and hardware tested as a separate unit, the

module concept also makes it easier to replace parts. All electronic modules

use connectors to make assembly and service fast and simple, no soldering

required.

Handle module

The handle module is common for all STR ETV and ETD models. It includes

the main electronic board, the board and its components are molded into

plastics for extra protection. The module also carries the vibrator, which can

be programmed to give feed back to the operator.

The gyroscope is another key component in the handle as it can sense

movements of the tool down to 1 degree.

The cable connection has a new generation of pins and sleeves that

increases the wear resistance considerably compared to previous

generations.

The trigger is easily removed for better accessibility during cleaning.

HMI

The HMI module is where the tool and operator interact with each other. The

module has LED lights – yellow, green or red. There is also a blue LED and

a tightening direction indicator. The reverse ring is lockable and the module

also includes a speaker that can send sound signals to the operator.

The standard HMI and EHMI is available with or without a button on the

reverse ring.

ETD ETV

ETPETT

Loading...

Loading...