Azbil Corporation Installation

Model VFR - FloWing Eccentric Rotary type Control Valves 1-3

1-3 : Inspecting and maintaining the

installed valve

Follow the procedures given below when inspecting or servicing an installed valve.

(1) Verify that there is no leak from the air piping.

(2) Verify that there are no loose clamping-bolts or nuts on the diaphragm case.

(3) Verify that there is no leak from the gland packing. Tighten the packing ange

nuts as required.

(4) Verify that there is no leak from the piping gaskets and check for loose clamping

bolts and nuts.

(5) To lubricate a valve which is equipped with a lubricator, proceed as follows:

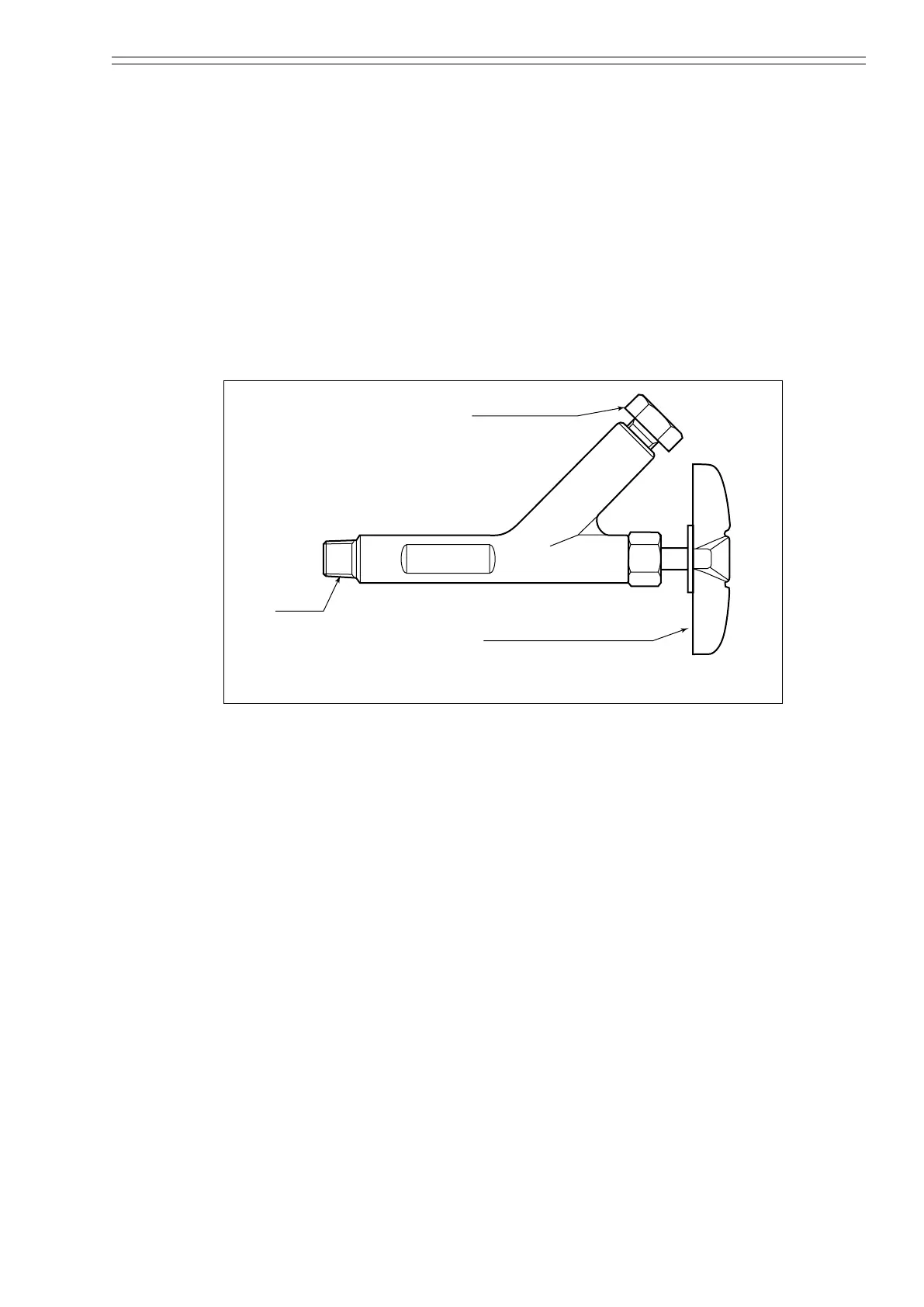

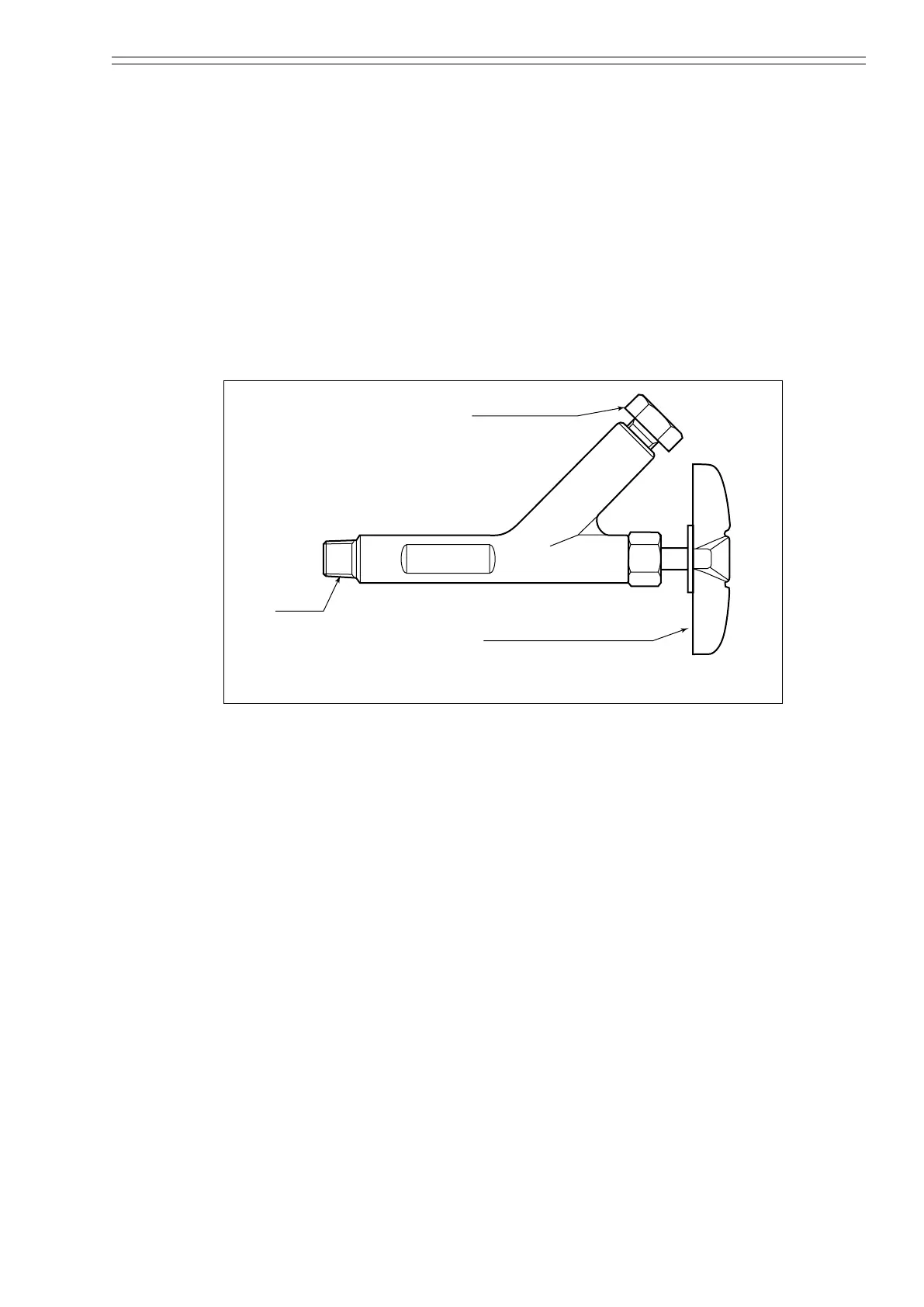

Lubricator handwheel

RC1/4

Figure 1-3 Lubricator

(a) Prepare the correct type of grease by referring to the grease number written on

the nameplate.

(b) Tightly close the lubricator handwheel.

(c) Remove the squeezer and apply grease.

(d) While opening, squeeze grease into the valve by rotating the squeezer.

(e) Repeat steps (b), (c) and (d) until grease in suciently fed into the valve.

Then, close the lubricator handwheel.

Loading...

Loading...