Technical Support: 1-877-995-8155

5

ANCHORING PLATE INSTALLATION

Inspect all components of the gate to insure proper manual operation and smooth sliding.•

Gate must slide freely and smoothly throughout its travel.•

Make sure that mechanical stops preventing the gate from slipping off the upper guide when manually op-•

erated are present and sound enough.

The gate track must be horizontal and straight. Non straight track will not allow proper operation of pinion •

and rack.

STEP 1

CAUTION:

Never install the rack prior to installation of the operator,

installing the rack before the operator will not allow proper mesh of

pinion and rack.

The operator has to be installed at the opening post edge.

Dig a hole for the concrete pad.•

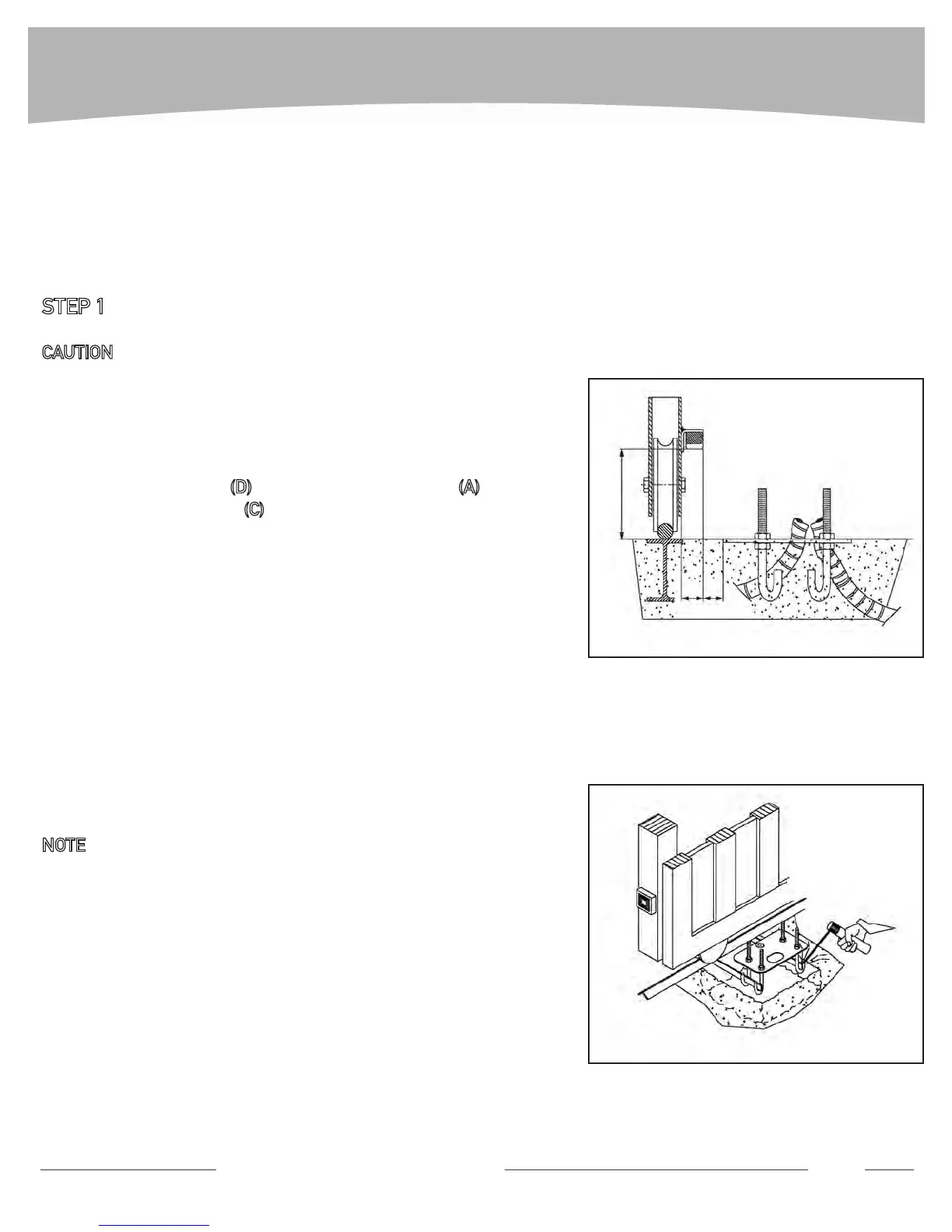

Using provided nuts • (D), bolt the anchoring hooks (A) to the posi-

tioning template plate (C). The template plate must be positioned

all the way down to the thread of the hooks.

Measurements for the positioning of the template plate are shown•

in Fig. 1. It is required at this stage to take into consideration the

thickness of the rack as it is important to position the template

plate so that rack-template plate distance is 0.9” (rack not in-

stalled yet at the moment). For CP rack T measure is 1.57”, for

CVZrackTmeasureis1.45”.

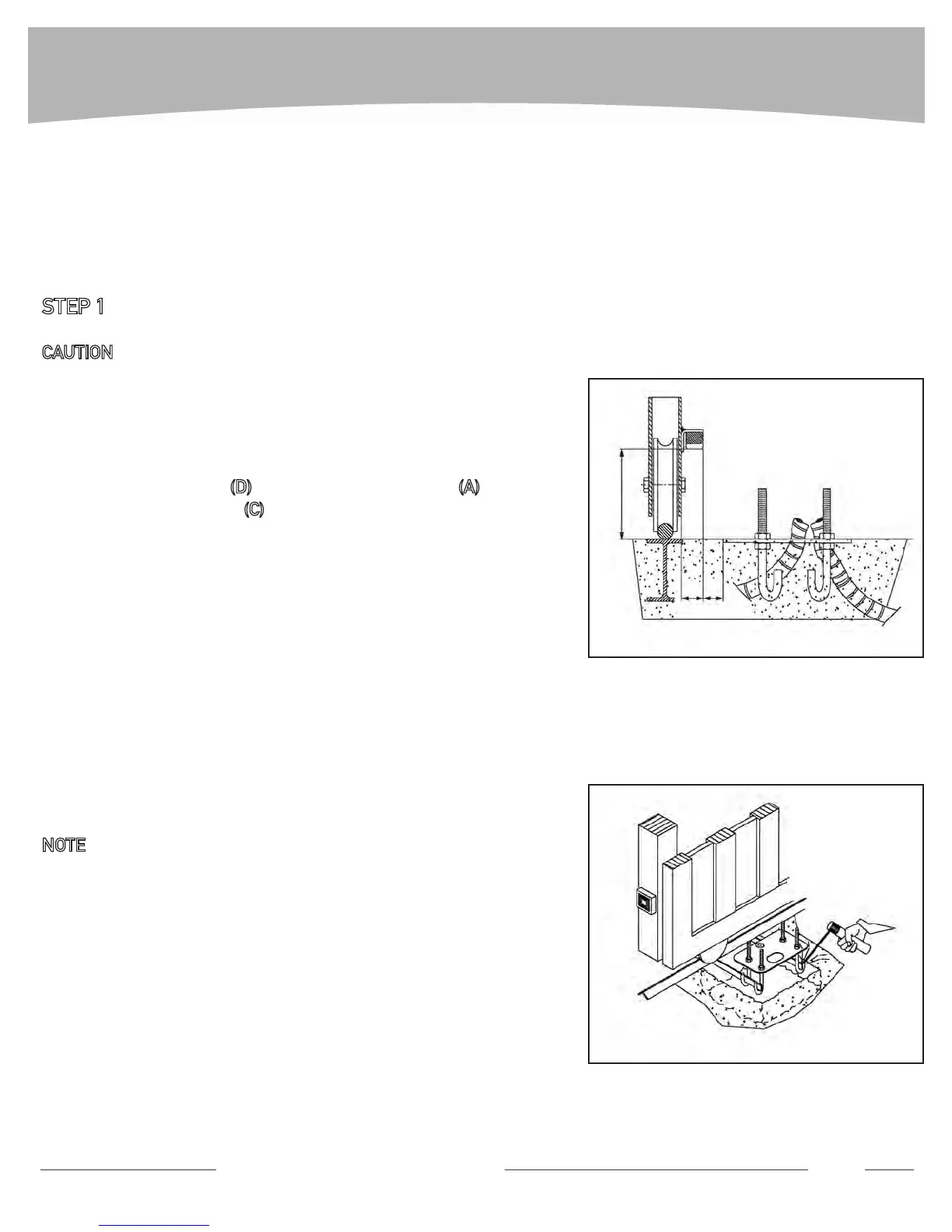

Position the template plate in the hole, make sure it is level. The template plate must have the pinion en-•

gravingnexttothegate.Incasetheholecanbeexecutedunderthetrack,itissuggestedtoweldtwosteel

bars across the anchoring hooks and the track of the gate as shown in Fig. 2, so that if the track sags, the

concrete pad will sag too, keeping the play between pinion and rack constant over time.

Remember that cable conduits have to pass through the hole in •

the template plate. Pour concrete.

NOTE:ifaconcretepadisalreadyexisting,theinstallationcanbe

carried out simply drilling holes in the concrete pad using the tem-

plate plate as reference and anchoring the operator using chemical

anchors and threaded bars instead of anchoring hooks (chemical

anchors, threaded bars and nuts not provided).

Rack: CP -> T = 1.57”

CVZ ->T=1.45”

Min 3.9”

0.9”T

FIG. 1

FIG. 2

Loading...

Loading...