[!]

Presser

foot

adjustment

~

3.5

mm---r----

1

·

[!]

Thread

wiper

adjustment

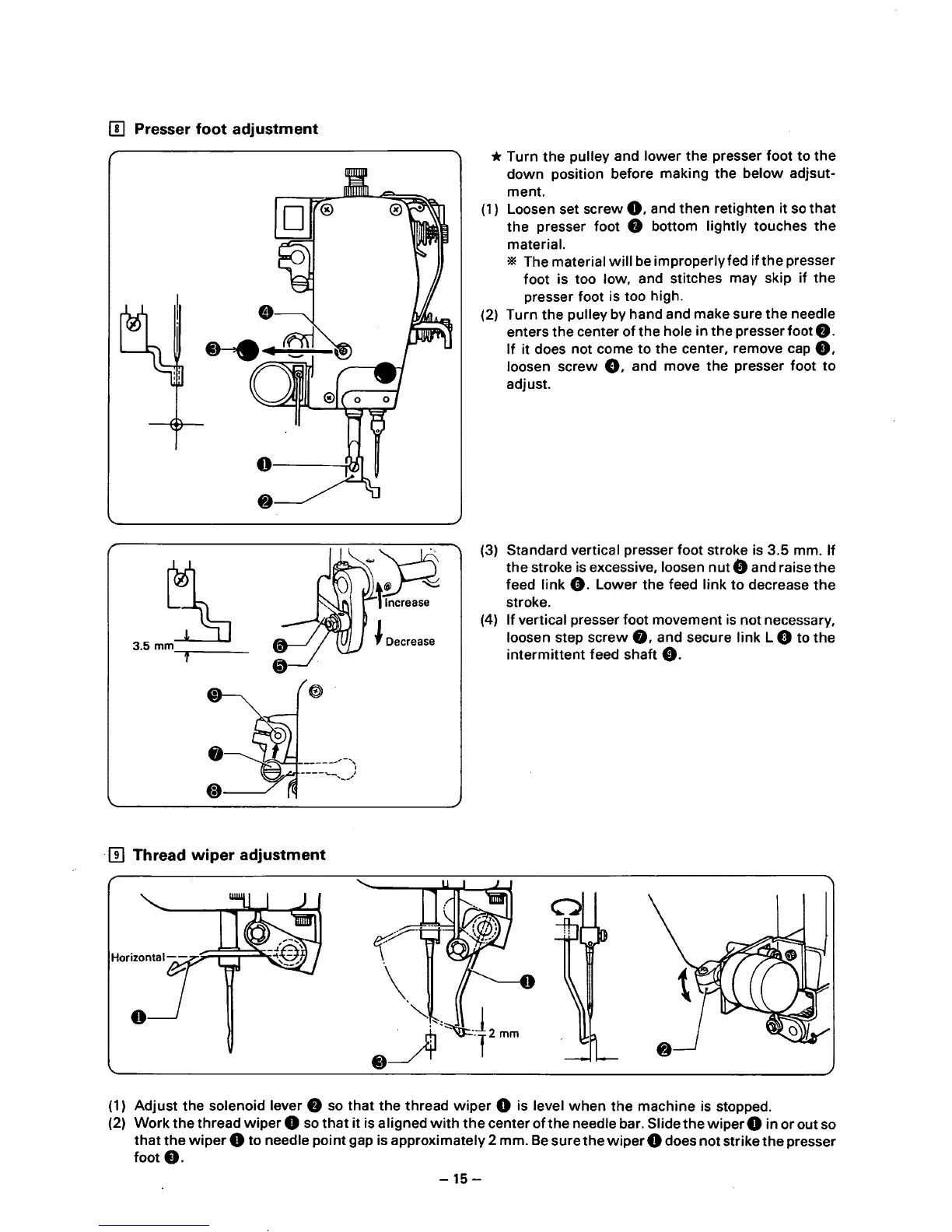

*Turn

the

pulley and

lower

the

presser

foot

to

the

down

position before making

the

below

adjsut-

ment.

(1) Loosen set screw

0,

and

then

retighten it so

that

the

presser foot

f)

bottom lightly touches

the

material.

* The material

will

be improperly fed

if

the

presser

foot is too low, and stitches may skip

if

the

presser foot is too high.

(2)

Turn

the pulley by hand and make sure

the

needle

enters

the

center

of

the

hole

in

the

presser foot

8.

If it does not come

to

the center, remove cap

0.

loosen

screw

e.

and move

the

presser foot

to

adjust.

(3) Standard vertical presser foot stroke is 3.5 mm. If

the

stroke is excessive, loosen

nut

0 and raise

the

feed

link

8.

Lower the feed

link

to

decrease

the

stroke.

(4)

If vertical presser foot movement is not necessary,

loosen step

screw

8,

and secure

link

L 0 to

the

intermittent

feed shaft

8.

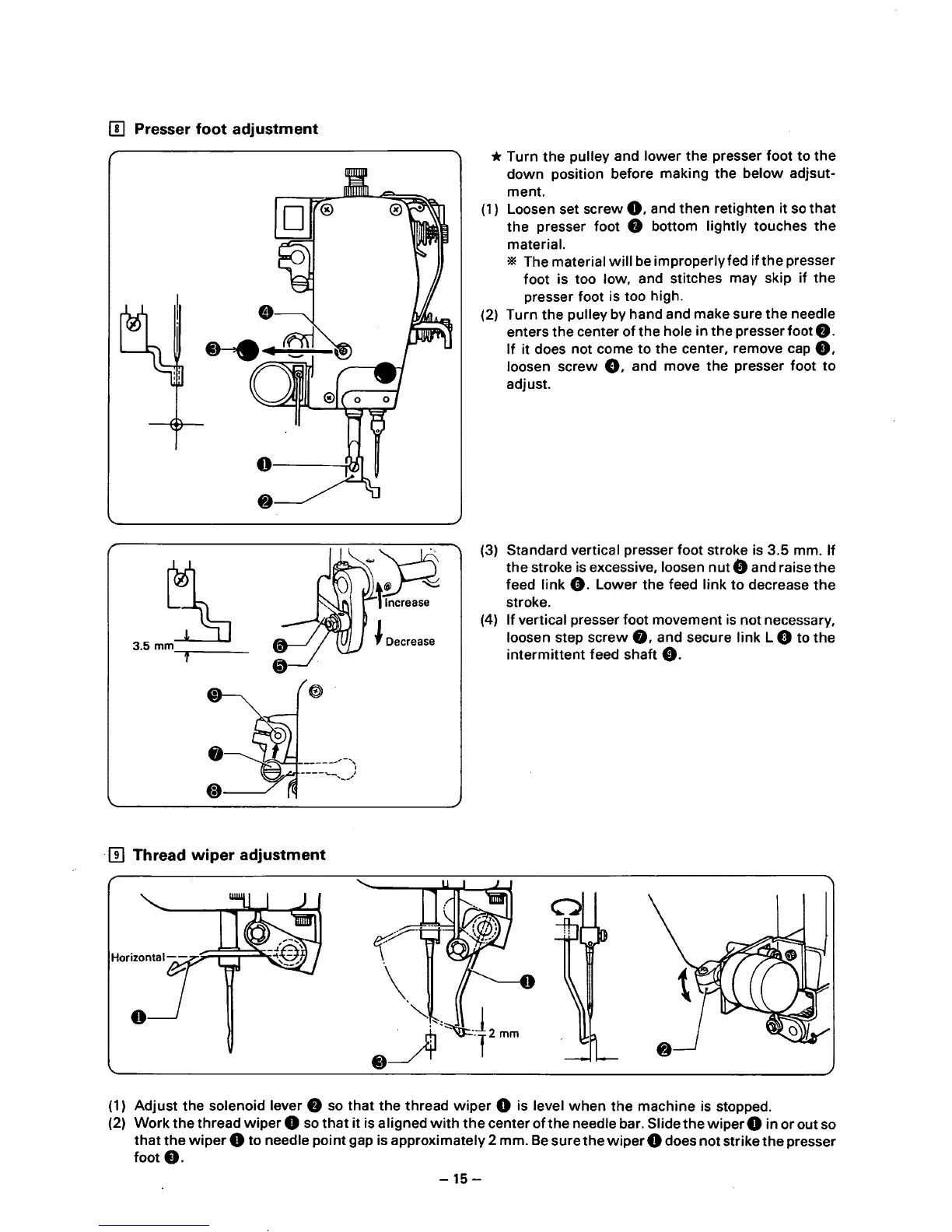

(1)

Adjust

the solenoid lever 8 so

that

the

thread

wiper

0 is level

when

the

machine is stopped.

(2)

Work

the

thread

wiper

0 so

that

it is aligned

with

the

center

oft

he needle bar. Slide

the

wiper

0 in

or

out so

that

the

wiper

0

to

needle

point

gap is

approximately2

mm.

Be

sure

the

wiper

0 does

not

strike

the

presser

footO.

-15-

Loading...

Loading...