Loading...

Loading...

Do you have a question about the Brother KE-430D and is the answer not in the manual?

| USB Port | Yes |

|---|---|

| Sewing Speed | Adjustable |

| Needle | HAx1 |

| Display | LCD screen |

| Embroidery Area | 4" x 4" (100mm x 100mm) |

| Stitch Type | Utility, decorative |

| Stitch Length | Adjustable |

| Bobbin | Drop-in bobbin |

| Type | Electronic Combination Sewing & Embroidery Machine |

Identifies KE-4300 as bar tacker, BE-4380 as button sewer.

Explains safety terms, symbols, operational rules, and warnings.

Details technical specifications for KE-4300 and BE-4380 models.

Covers special, advanced, memory, and CF card settings.

Describes major mechanisms like needle bar, feed, and trimmer systems.

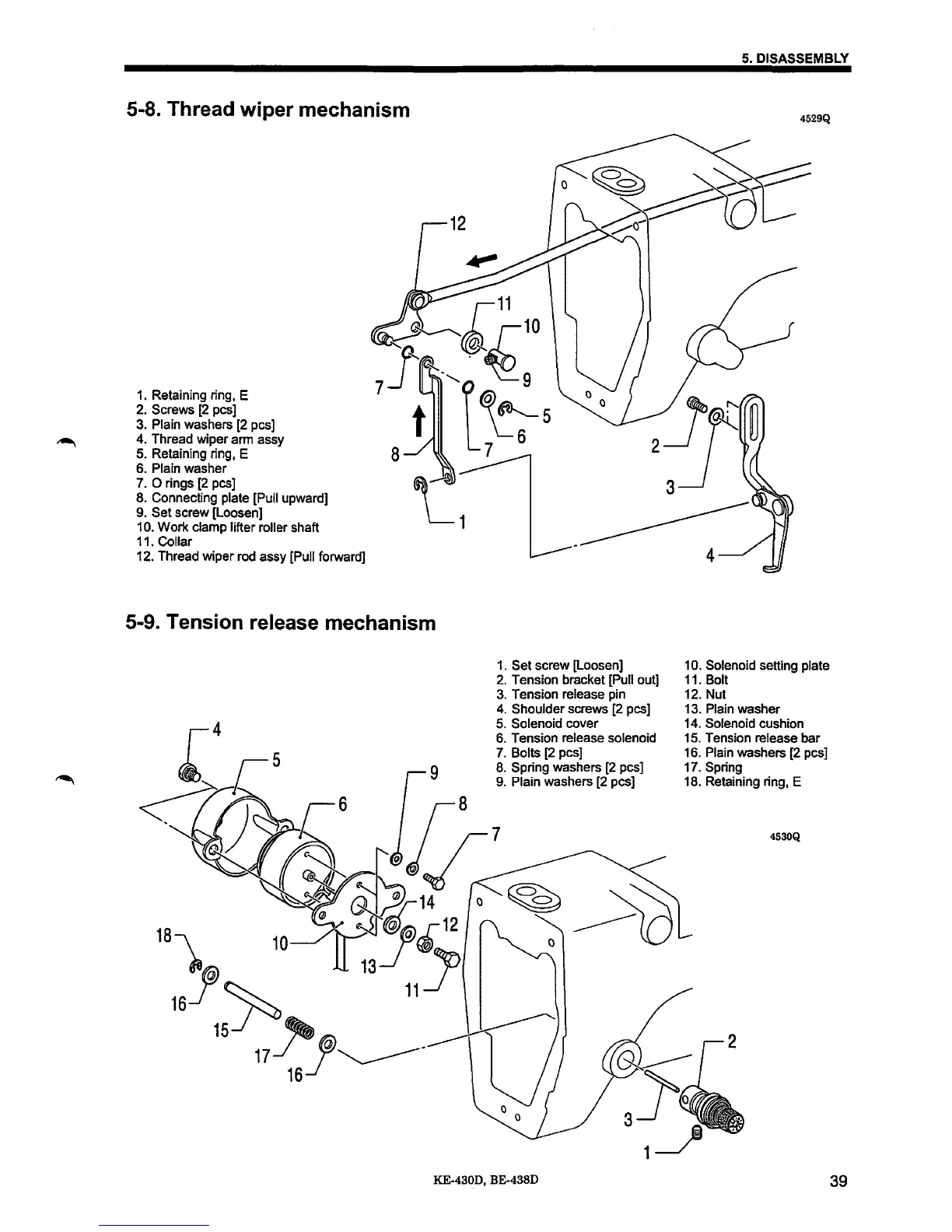

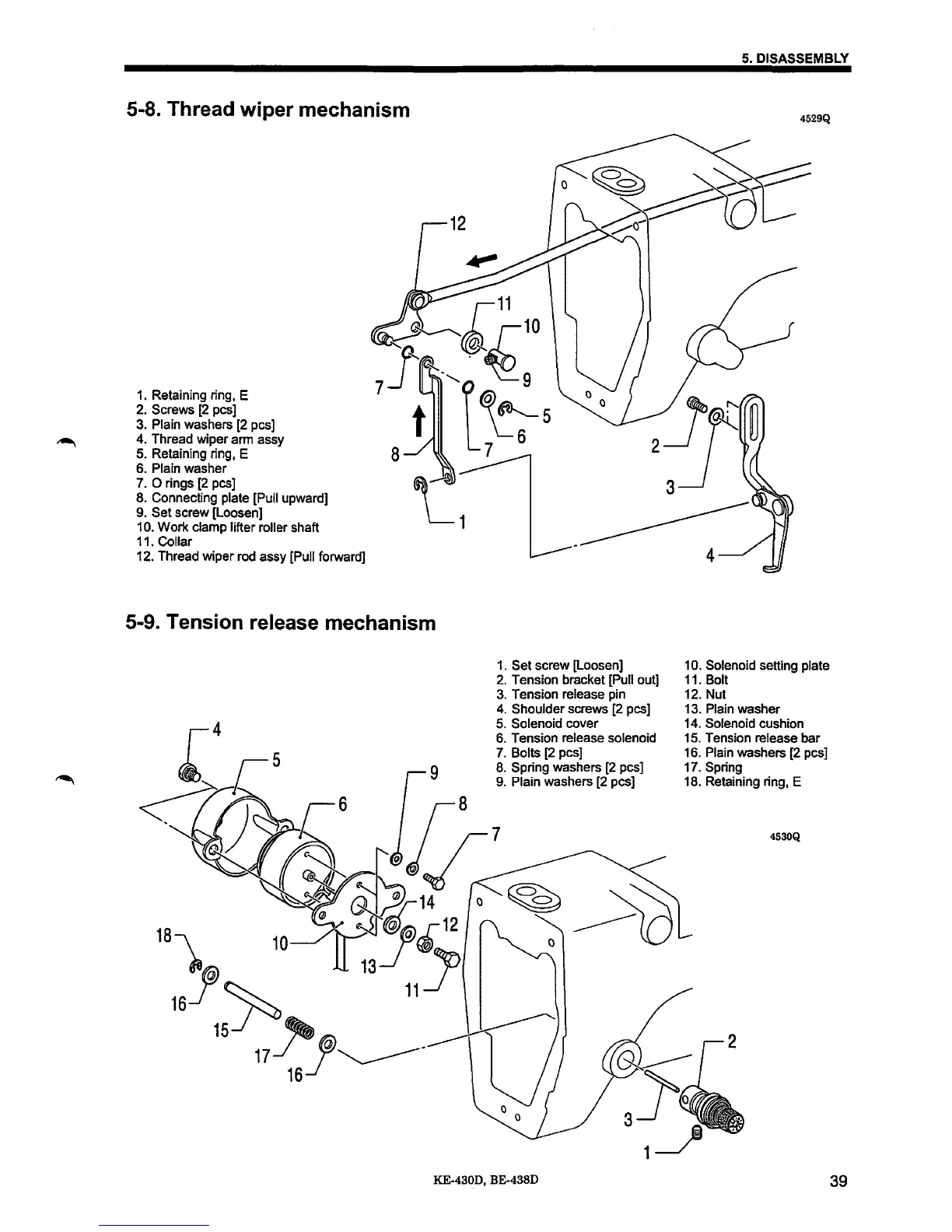

Provides step-by-step instructions for disassembling and assembling machine components.

Details adjustments for thread tension, mechanisms, home positions, and timing.

Explains the "GREASEUP" prompt and the grease application process.

Covers control box components, fuses, connectors, and error codes.

Lists error codes by category and provides remedies for malfunctions.

Instructions for correctly connecting the ground wires.