7. ADJUSTMENT

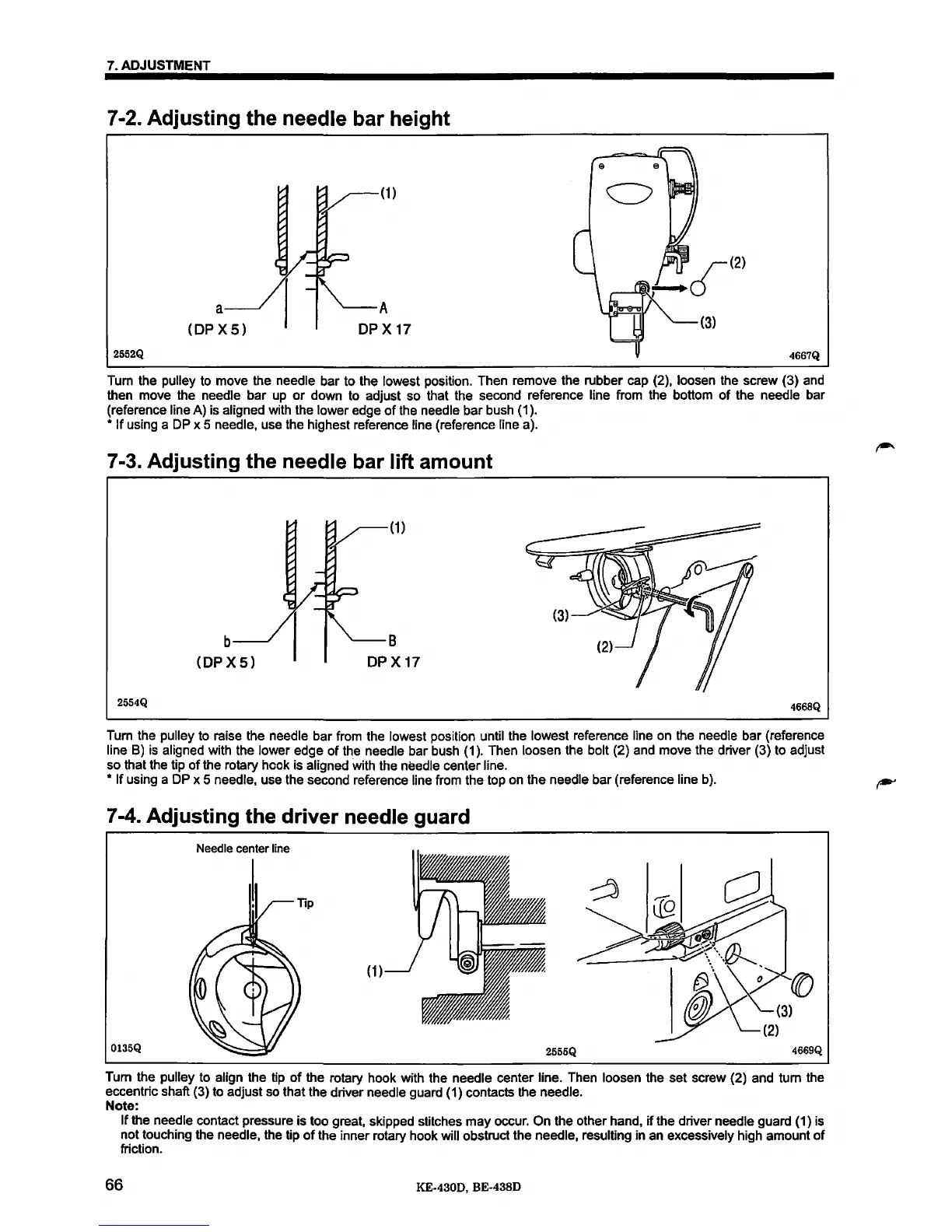

7-2. Adjusting the needle bar height

2552Q

a

(DP

XS)

(1)

A

DPX

17

4667Q

Tum the pulley to move the needle bar to the lowest position. Then remove the rubber cap (2), loosen the screw (3) and

then move the needle bar

up

or

down to adjust so that the second reference line from the bottom

of

the needle bar

(reference

line A) is aligned with the lower edge

of

the needle bar bush

(1

).

•

If

using a DP x 5 needle, use the highest reference line (reference line a).

7-3. Adjusting the needle bar lift amount

2554Q

b

(DP X

5)

(1)

B

DPX

17

4668Q

Tum the pulley to raise the needle bar from the lowest position until the lowest reference line on the needle bar (reference

line

B)

is

aligned with the lower edge

of

the needle bar bush

(1

).

Then loosen the bolt (2) and move the driver {3) to adjust

so that the tip

of

the rotary hook is aligned with the needle center line.

•

If

using a DP x 5 needle, use the second reference line from the top on the needle bar (reference line b).

7-4. Adjusting the driver needle guard

Needle

center line

(1)

0135Q

2555Q

4669Q

Tum the pulley to align the tip

of

the rotary hook with the needle center line. Then loosen the

set

screw (2) and tum the

eccentric shaft (3) to adjust so that the driver

needle guard (1) contacts the needle.

Note:

If

the needle contact pressure is too great, skipped stitches

may

occur.

On

the other hand,

if

the driver needle guard (1) is

not

touching the needle, the tip

of

the inner rotary hook will obstruct the needle, resulting in an excessively high amount

of

friction.

66

KE·430D,

BE-4380