18

ENG

easy/easy compact/easy split +030220791 - rel. 3.2 - 13.07.2010

/6: disable decimal point

Used to enable or disable the temperature display with the resolution to

the tenths of a degree between -20 and + 20 (easy and easy split) or -10

and +10 (easy compact).

/6= 0 temperature displayed to the tenth of a degree;

/6=1 temperature displayed without the tenths of a degree.

Note: the decimal point is only disabled in relation to the reading

shown on the display (the calculations performed by the controller

remain unchanged).

/7: enable probe 2 alarm (M models only)

In the thermometer models (M), tted with two probes, setting /7= 1

enables the alarm relating to the second probe (E1).

4.3 Temperature control

The following parameters are used to control the temperature: St, r1, r2,

r3, r4 and rd.

St: set point, r1 minimum value and r2 maximum value of the set

point

Parameter St determines the desired temperature to be maintained inside

the cabinet or cold room (set point). Parameters r1 (minimum value) and

r2 (maximum) set the range of temperatures for setting the set point.

Note: the set point can be set by pressing the SET button (see par.

“Setting the set point (desired temperature value)” page 16).

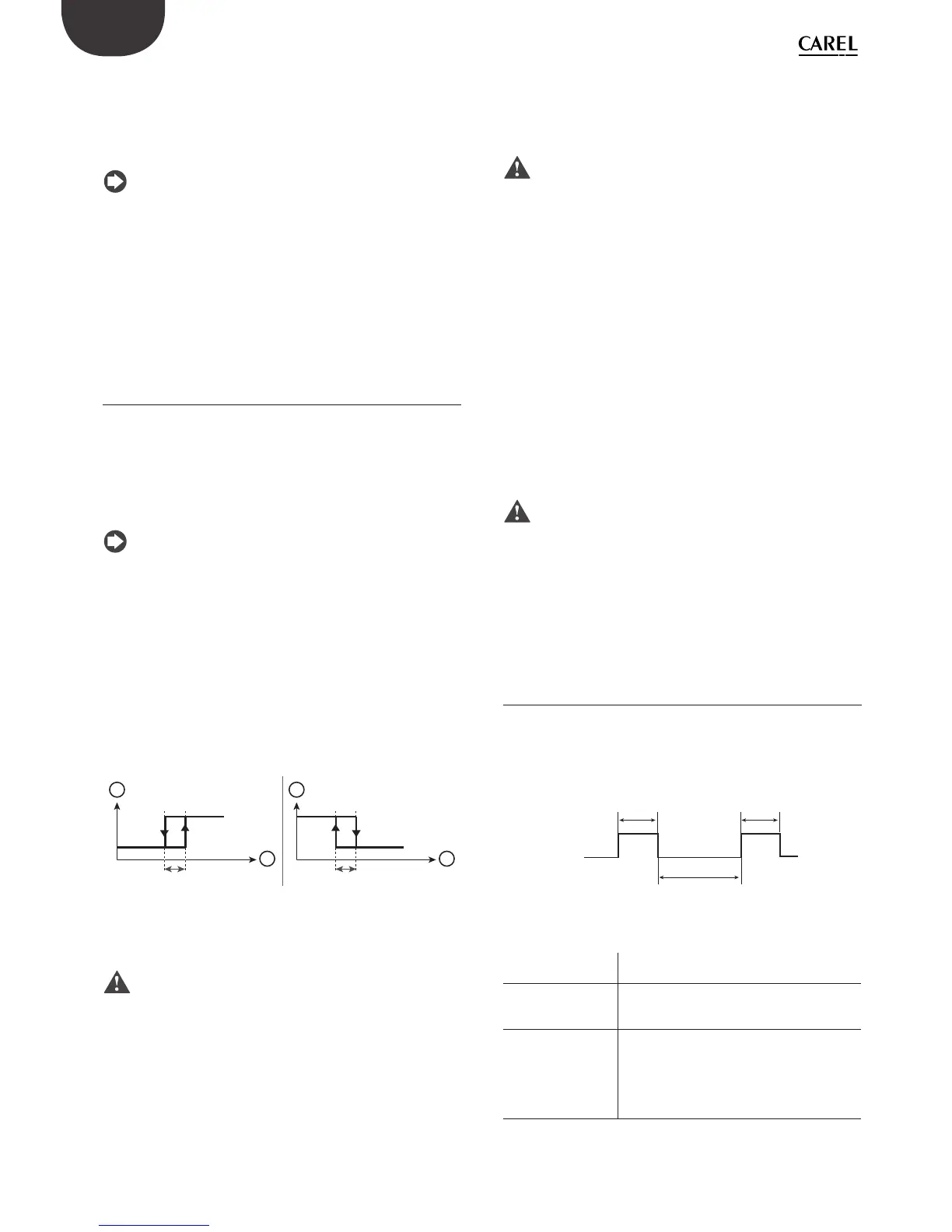

r3: select direct/reverse operation

De nes the operating mode of the device:

• r3=0: direct with defrost. Used to request the activation of the

compressor when the temperature measured by probe 1 rises above

the set point. This mode also includes defrost (also called “cooling”

mode, see Fig. 4.a)

• r3=1: direct without defrost (Fig. 4.a)

• r3=2: reverse without defrost (Fig. 4.a). Used to request the activation

of the compressor when the temperature measured by probe 1 falls

below the set point. This mode does NOT include defrost (also called

“heating” mode, see Fig. 4.a).

“Direct” mode (cooling) “Reverse” mode (heating)

OFF

ON

set point

rd

1

2

OFF

ON

set point

rd

1

2

Fig. 4.a

Key:

1. compressor request;

2. probe 1

Important: the operating mode can also be set by external

contact connected to the multifunction digital input (parameter

A4=9). In this case, the contact controls operation (direct/reverse) with

priority over parameter r3.

r4: night-time set point delta

Value that automatically increases the set point temperature during the

night-time operation time bands.

r4=0: night-time set point= St

r4>0: night-time set point= St + r4

Important:

1. to enable night-time operation, not only does r4 need to be set >0, but

the digital input must also be enabled and con gured (see parameter

A4=4 curtain switch/night-time operation) or a night-time time band

enables (see par. “4.11 Clock and time band parameters” page 28);

2. night-time operation does not necessarily mean at night, but rather

the time bands in which the value of the set point is modi ed. This

usually corresponds to the period in which the refrigerated cabinet is

not used (shop closed) and when the curtain is down.

rd Control di erential

Value that is added to (or subtracted from, in ‘reverse’ mode) the

temperature set point.

rd= low values:

• more precise temperature control;

• high compressor On/O switching frequency in the event of minimum

temperature deviations (with the risk of causing damage).

rd= high values:

• less precise temperature control;

• low compressor On/O switching frequency in the event of minimum

temperature deviations.

Important: the compressor can also be safeguarded using the

parameters that limit the number of activations/hour and the

minimum o time (see par. “4.6 Compressor protection” page 19).

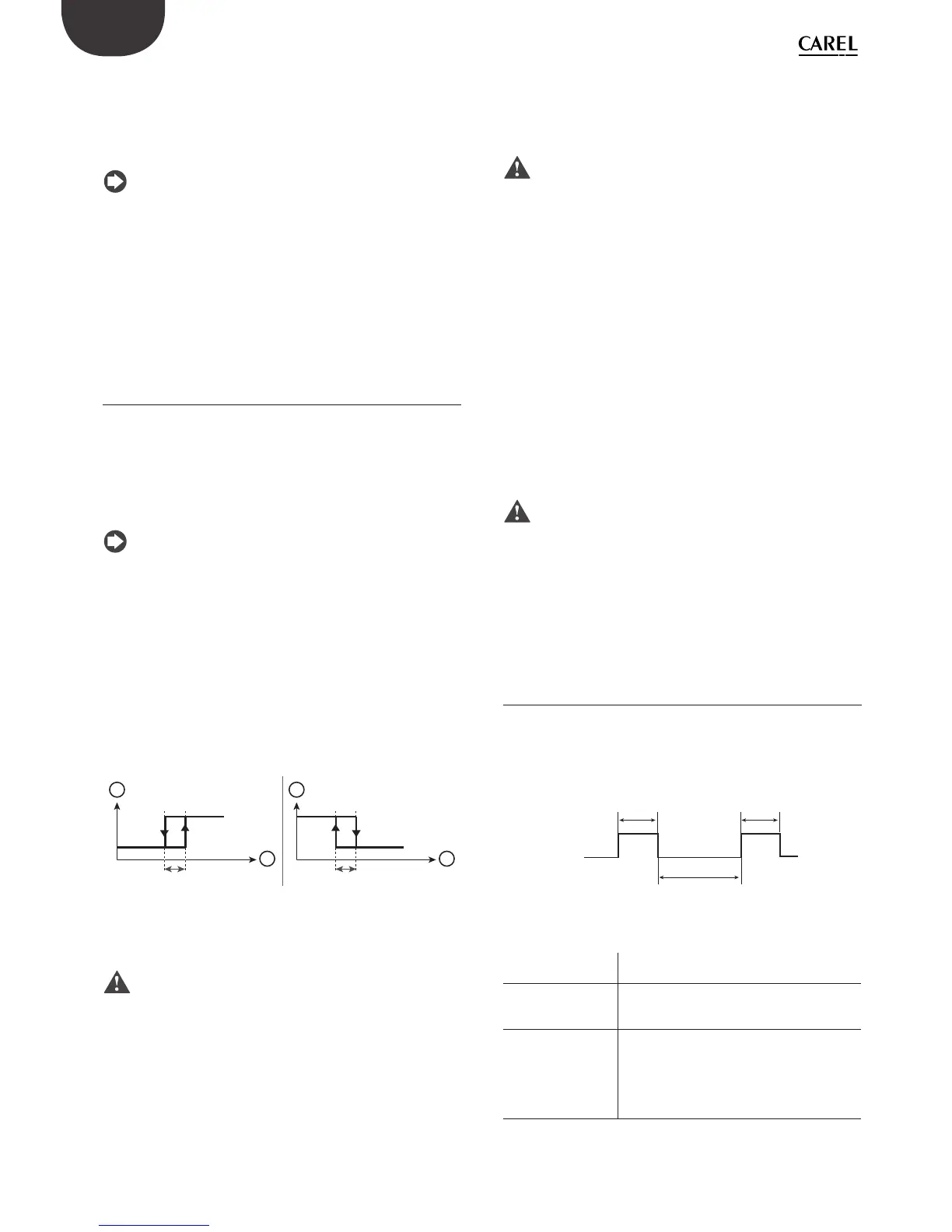

4.4 Duty Setting

Safety function that ensures the operation of the compressor even in the

event of a control probe fault. If alarm E0 occurs, duty setting ensures the

operation of the compressor until the fault is resolved. The compressor,

not being able to be activated according to temperature, works cyclically

with an ON time equal to the value assigned to parameter c4 (in minutes)

and a xed OFF time of 15 minutes, see Fig. 4.b.

ON

OFF

C4

compressor

C4

OFF= 15 min.

Fig. 4.b

c4: compressor on time with duty setting

c4= 0 in the event of an ambient probe fault, the

compressor will be always o

c4= 100

(c4=99

for easy compact)

the compressor will remain always on; and the

15 minute o time is not considered.

0<c4<100

(0<c4<99

for easy compact)

at the moment a probe error (E0) is detected, the

duty setting cycle starts from the current status

of the compressor (that is, the status of the

compressor is maintained) and the time already

elapsed is ignored. The compressor times set by

parameters c1, c2, c3 are always observed.

Table 4.d

Loading...

Loading...