2

CONTENTS

Page

SAFETY CONSIDERATIONS ......................1

INTRODUCTION ..................................2

INSTALLATION ................................ 2-10

Complete Pre-Installation Checks ................2

• IDENTIFY UNIT

• INSPECT SHIPMENT

Mount the Pumpout Unit .........................3

• MOUNTING ON THE CHILLER

• FLOOR MOUNTING

Rig the Storage Tank .............................3

Make Piping Connections ........................6

• INSTALL VENT PIPING TO RELIEF DEVICES

Make Electrical Connections .....................6

CONTROLS AND COMPONENTS ................11

Pumpout Unit ...................................11

• CONTROLS

• SAFETY CONTROL SETTINGS

• COMPRESSOR

• CONDENSER

•OILSEPARATOR

• SUCTION AND DISCHARGE VALVES

Storage Tank ....................................11

•DRAINVALVE

• DUAL RELIEF VALVES

• PRESSURE GAGE

• LEVEL GAGE

OPERATION .................................. 11-15

Overview ........................................11

• REFRIGERANT TRANSFER

• TRANSFERRING LIQUID REFRIGERANT FROM

THE CHILLER COOLER TO THE CHILLER

CONDENSER OR PUMPOUT STORAGE TANK

• TRANSFERRING LIQUID REFRIGERANT FROM

THE CHILLER CONDENSER OR PUMPOUT

STORAGE TANK TO THE CHILLER COOLER

• DISTILLING THE REFRIGERANT

Pumpout and Refrigerant Transfer Procedures ..12

• OPERATING THE PUMPOUT UNIT

• TO READ REFRIGERANT PRESSURES

• POSITIVE PRESSURE CHILLERS WITH STORAGE

TANKS

• CHILLERS WITH ISOLATION VALVES

• DISTILLING THE REFRIGERANT

MAINTENANCE............................... 15,16

Pumpout Compressor Oil Charge ...............15

Storage Tank ....................................16

Ordering Replacement Parts ....................16

TROUBLESHOOTING............................16

INTRODUCTION

The 19XR Positive Pressure Storage (PPS) System has been

designed to help owners and operators of positive pressure

chillers store HFC-134a refrigerant during service and repair

work. The 19XR system conserves this refrigerant and pre-

vents the release of excessive amounts of refrigerant into the

atmosphere. The proper use of this equipment minimizes the

loss of HFCs.

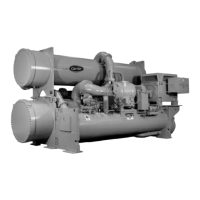

The 19XR PPS system shown in Fig. 1 consists of a pump-

out unit mounted on a storage tank. The pumpout unit is

offered as a free-standing unit that can be used with chillers

that have an existing storage tank or with chillers that have iso-

lation valves that permit built-in refrigerant storage.

The 19XR PPS systems are factory tested and certified to

the American Society of Mechanical Engineers (ASME) pres-

sure vessel code. The tanks are constructed of certified steel

and are pressure rated at 185 psig (1276 kPa). The PPS storage

tank is equipped with dual relief valves for proper venting per

ASHRAE 15 (American Society of Heating, Refrigeration, and

Air Conditioning Engineers) guidelines. An automatic level

switch is prewired to the control circuit to ensure proper stor-

age levels.

The 19XR pumpout unit is a complete, hermetic, compact

unit that consists of:

• a hermetic reciprocating compressor with a direct-drive

motor

• a water-cooled refrigerant condenser

• an oil separator

• suction and discharge valves to control refrigerant flow

• prewired safety and control devices.

INSTALLATION

Complete Pre-Installation Checks

IDENTIFY UNIT — Identify the assembly number (Table 1)

printed on the pumpout unit and storage tank nameplates.

Check this information against the job requirements. Fig. 1

shows the PPS system and its major components. Refer to

Tables 2 and 3 for physical data.

INSPECT SHIPMENT — Inspect unit for damage before

removing unit from shipping conveyance. If unit appears dam-

aged, it should be inspected by a shipping inspector before

removal. File a claim with the shipping company if shipment is

damaged or incomplete. The manufacturer is not responsible

for damage incurred during transit.

Check all components. Notify the supplier immediately if

any item is missing. To prevent loss or damage, leave all parts

in their original package until they are needed.

Loading...

Loading...