31

LEDs

There are two LEDs (red and green) on the electronic board

which indicate its status (see Fig. 43).

Intermittent green LED: The board status is correct.

Green LED off: The following steps should be taken:

1. Check whether there is 24 V AC running through the B1

connections on the board (see Fig. 43).

2. If there is, replace the board with a new one.

3. If there is none, look for the fault in the unit electrical

system and repair it.

4. Recheck the B1 connections.

Green LED on: Replace the board.

Red LED off: The status is correct.

Red LED on: Three possibilities:

1. Defective connection between the main board and the

secondary board. Check CO1 (Figs. 43 and 44)

connection. Check the status of the connecting cable.

2. Remote control incorrectly connected.

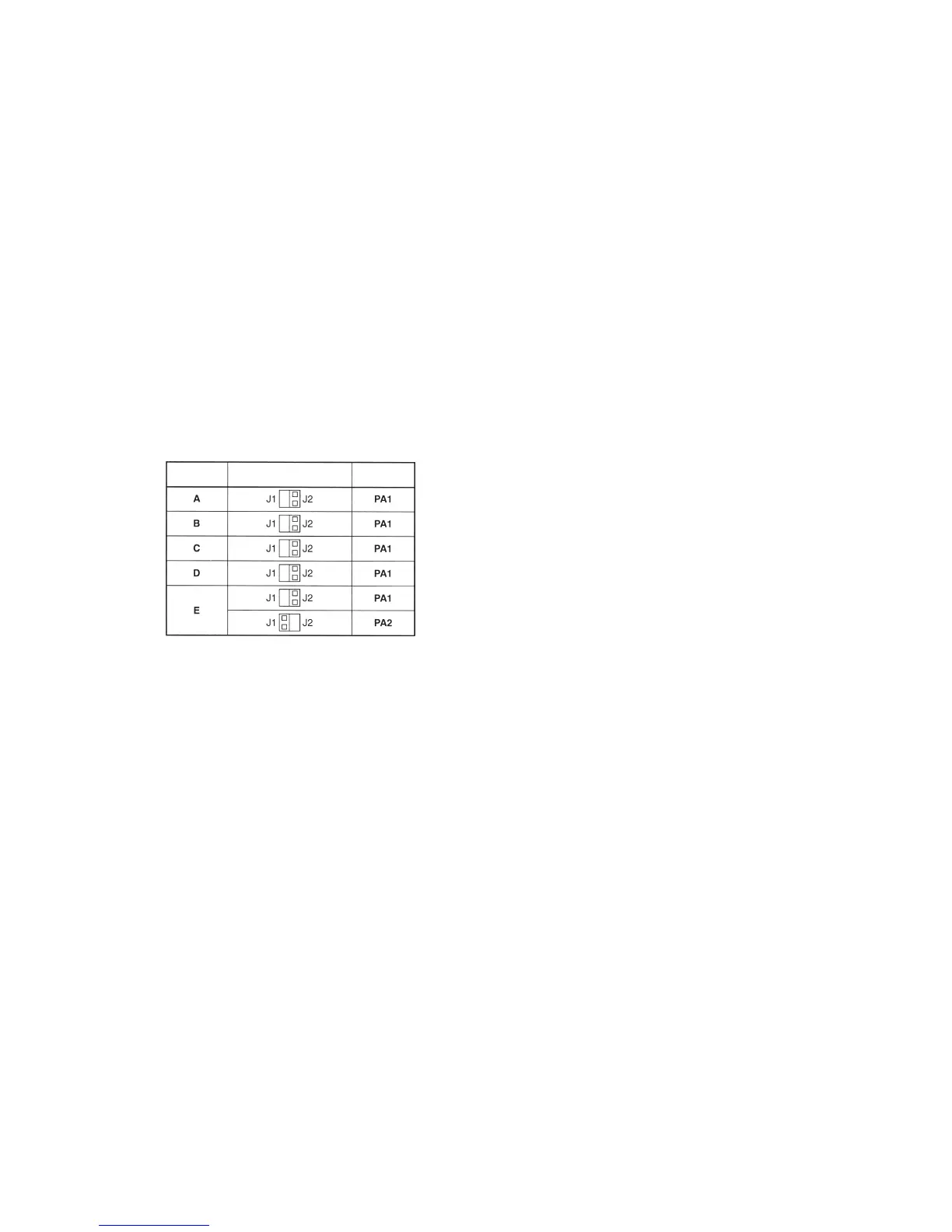

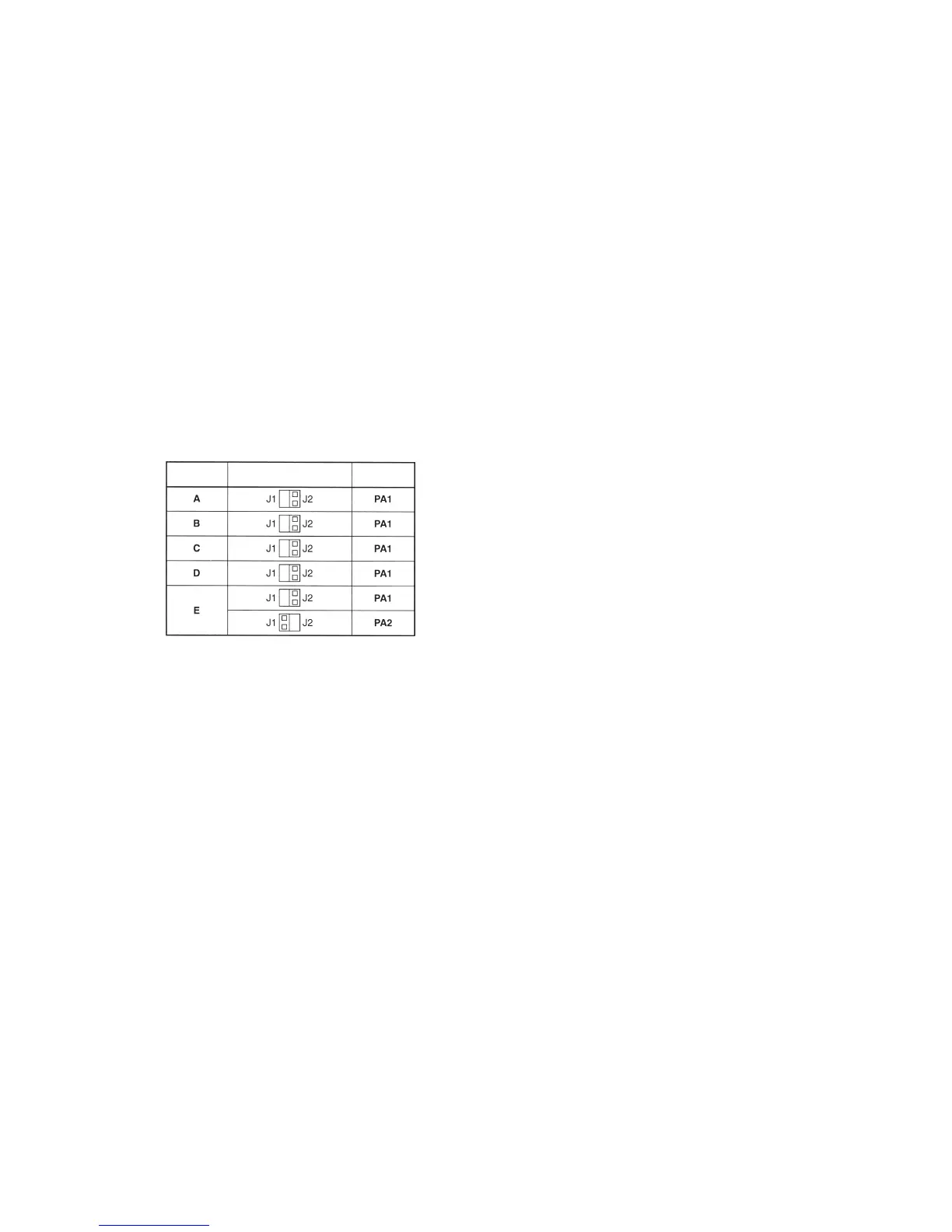

3. The secondary board jumpers J1 and J2 (Fig. 44) are

incorrectly connected. In order to correct this, use the table

below.

Table 9 - Secondary board jumpers

A: Cooling only models with 1 compressor + electric heater

in indoor unit.

B: Cooling only models with 2 compressors + electric heater

in indoor unit.

C: Heat pump models with 1 compressor + electric heater in

indoor unit.

D: Heat pump models with 2 compressors + electric heater in

indoor unit.

Intermittent red LED: DIP-switch No. 1 in OFF position (see

Fig. 43).

CAUTION: When the red LED is illuminated intermittently

do not try to start up the unit. To correct this status, DIP-

switch No.1 must be in the ON position after having been

RESET.

REFRIGERANT LINE CONNECTIONS

Connection between units

The 38XTZ outdoor units must be connected with the 40ABZ/

ALZ indoor units with refrigerant-grade copper pipes for correct

operation.

For each compressor in the 38XTZ outdoor unit a pipe for

refrigerant gas and another pipe for liquid refrigerant must be

installed.

For copper-pipe refrigerant connection lines the following

points must be observed:

- Ensure that the line length is as short as possible.

- The number of bends or elbows must be the minimum

possible.

- Design the lines with the correct diameter for the required

compressor oil suction velocity.

- Route the lines so that they do not obstruct the normal

building use. Avoid exposing them to extreme high or low

temperatures.

- Install them where they cannot be damaged.

- If they are routed outside the building, protect them

against extreme temperatures and damaging environmental

influences.

- Insulate the suction line along its complete length, and the

liquid line when it passes through any support, wall, etc.

IMPORTANT: Always use refrigerant-grade deoxidized and

dehydrated copper tubing between the indoor and outdoor

units.

- Carefully protect the copper pipes during transport,

installation and connection, against possible ingression of

water or moisture.

- Also prevent entry of any contaminants or foreign

substances.

- Four operations are very important:

- Pipe cleaning

- Pipe leak tightness

- Correct leak tests

- Correct evacuation

- When pipes are soldered, cut or flared, etc. ensure that no

residue or shavings can enter the pipes. Blow any residue

away from the pipe ends and check them carefully.

Refrigerant piping design

The design and sizing of the pipe diameters depends on the unit

location which can be:

Model Correct connection Board

Loading...

Loading...