24

C12280

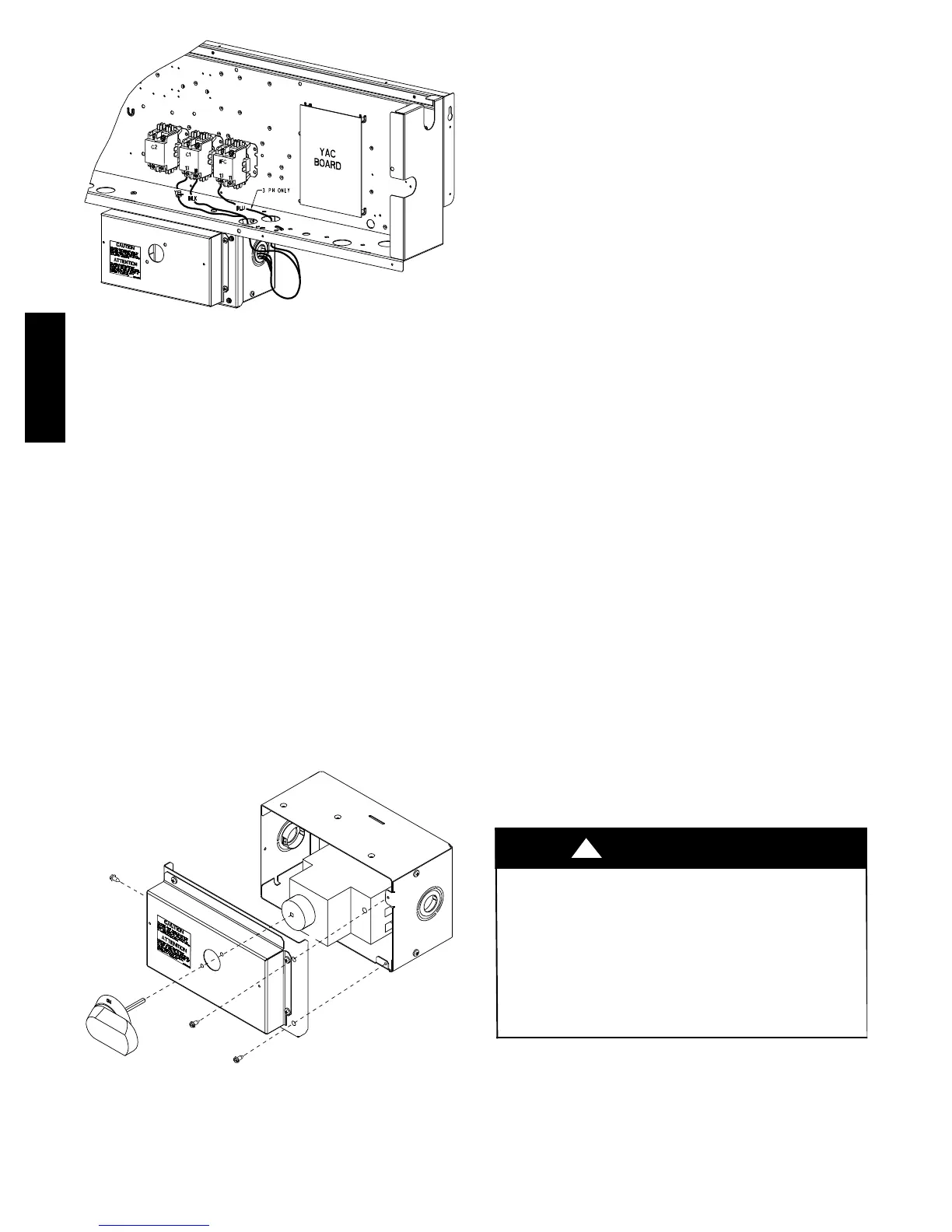

Fig. 34 -- Location of HACR Enclosure

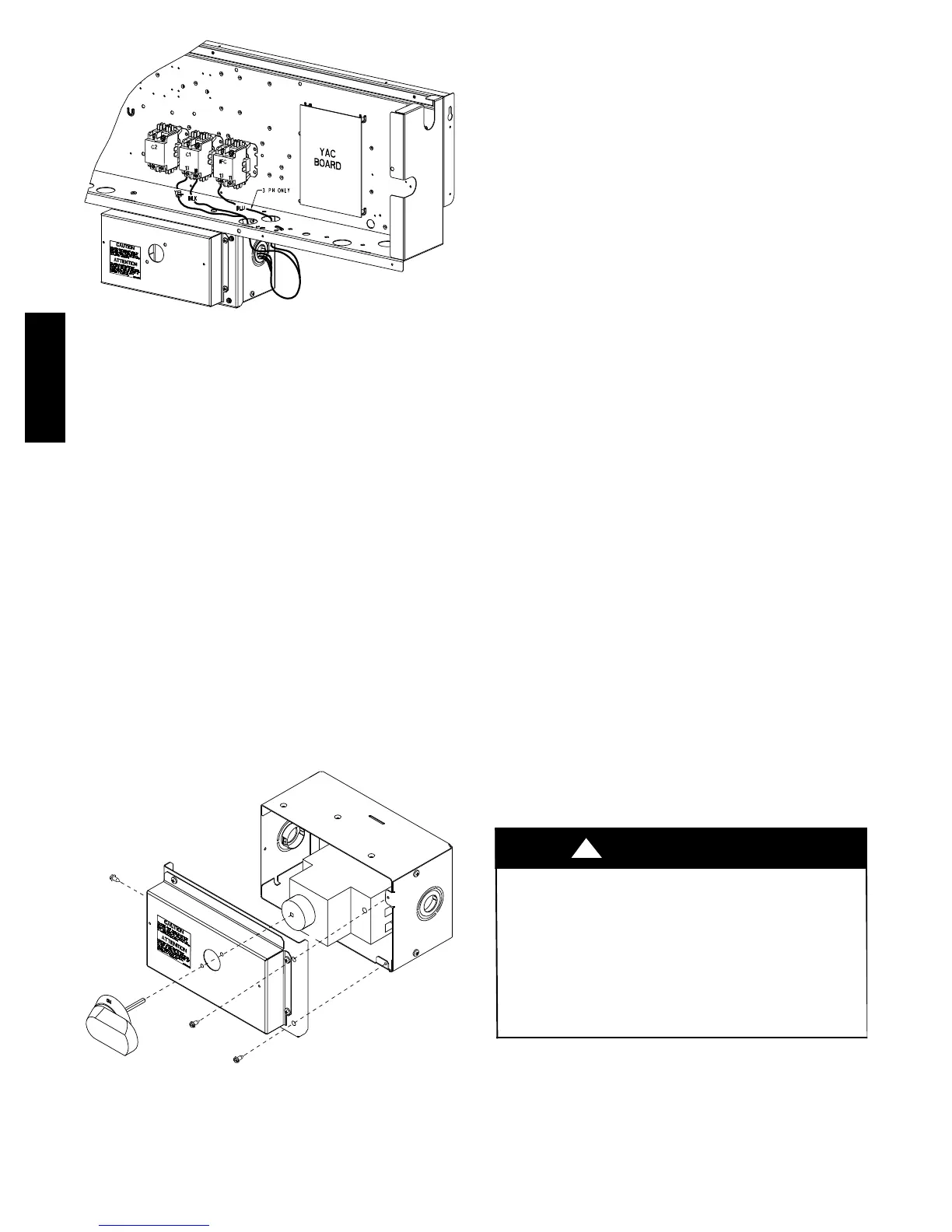

To field install the HACR shaft and handle:

1. Remove the unit front panel (see Fig. 2).

2. Remove (3) hexagon screws on the front cover -- (2)

on the face of the cover and (1) on the left side cover.

3. Remove the front cover of the HACR enclosure.

4. Make sure the HACR shipped from the factory is at

OFF position (the white arrow pointing at OFF).

5. Insert the shaft all the way with the cross pin on the

top of the shaft in the horizontal position.

6. Tighten the locking screw to secure the shaft to the

HACR.

7. Turn the handle to the OFF position with red arrow

pointing at OFF.

8. Install the handle on to the painted cover horizontally

with the red arrow pointing to the left.

9. Secure the handle to the painted cover with (2) screws

and lock washers supplied.

10. Engaging the shaft into the handle socket, re--install

(3) hexagon screws on the front cover.

11. Re--install the unit front panel.

C12281

Fig. 35 -- Handle and Shaft Assembly for HACR

Units Without Factory--Installed Non--Fused Disconnect

or HACR —

When installing units, provide a disconnect switch per

NEC (National Electrical Code) of adequate size.

Disconnect sizing data is provided on the unit informative

plate. Locate on unit cabinet or within sight of the unit per

national or local codes. Do not cover unit informative

plate if mounting the disconnect on the unit cabinet.

All Units —

All field wiring must comply with NEC and all local

codes. Size wire based on MCA (Minimum Circuit Amps)

on the unit informative plate. See Fig. 30 and the unit

label diagram for power wiring connections to the unit

power terminal blocks and equipment ground. Maximum

wire size is #2ga AWG per pole on contactors. #2ga AWG

per pole on optional disconnect or HACR. See Fig. 30 and

unit label diagram for field power wiring connections.

Provide a ground--fault and short--circuit over--current

protection device (fuse or breaker) per NEC Article 440

(or local codes). Refer to unit informative data plate for

MOCP (Maximum Over--current Protection) device size.

NOTE: Units ordered with factory installed HACR do

not need an additional ground--fault and short--circuit

over--current protective device unless required by local

codes.

All field wiring must comply with the NEC and local

requirements.

All units except 208/230-v units are factory wired for the

voltage shown on the nameplate. If the 208/230-v unit is

to be connected to a 208-v power supply, the control

transformer must be rewired by moving the black wire

with the

1

/

4

-in. female spade connector from the 230--v

connection and moving it to the 200-v

1

/

4

-in. male

terminal on the primary side of the transformer. Refer to

unit label diagram for additional information.

NOTE: Check all factory and field electrical connections

for tightness.

Convenience Outlets —

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Units with convenience outlet circuits may use multiple

disconnects. Check convenience outlet for power status

before opening unit for service. Locate its disconnect

switch, if appropriate, and switch to off position.

Lock--out and tag--out this switch, if necessary.

!

WARNING

Two types of convenience outlets are offered on 48LC

models: Non--powered and unit--powered. Both types

provide a 125--volt GFCI (ground--fault circuit--interrupter)

duplex receptacle rated at 15--A behind a hinged

waterproof access cover, located on the end panel of the

unit. See Fig. 36.

48HC48LC

Loading...

Loading...