93

TROUBLESHOOTING GUIDE

(TABLES 15-18B)

Overview —

The PIC III has many features to help the

operator and technician troubleshoot a 19XRV chiller.

• The ICVC shows the chiller’s actual operating conditions

and can be viewed while the unit is running.

• The ICVC default screen freezes when an alarm occurs. The

freeze enables the operator to view the chiller conditions at

the time of alarm. The STATUS screens continue to show

current information. Once all alarms have been cleared (by

correcting the problems and pressing the softkey),

the ICVC default screen returns to normal operation.

• The CONTROL ALGORITHM STATUS screens (which

include the CAPACITY, OVERRIDE, LL_MAINT,

VFD_HIST, LOADSHED, CUR_ALARM, WSM-

DEFME, and OCCDEFCM screens) display information

that helps to diagnose problems with chilled water tempera-

ture control, chilled water temperature control overrides, hot

gas bypass, surge algorithm status, and time schedule opera-

tion. See Table 15.

• The control test feature facilitates the proper operation and

test of temperature sensors, pressure transducers, the guide

vane actuator, oil pump, water pumps, tower control, and

other on/off outputs while the compressor is stopped. It also

has the ability to lock off the compressor and turn on water

pumps for pumpout operation. The ICVC shows the tem-

peratures and pressures required during these operations.

• From other SERVICE tables, the operator/technician can

access configured items, such as chilled water resets, over-

ride set points, etc.

• If an operating fault is detected, an alarm message is gener-

ated and displayed on the ICVC default screen. A more

detailed message — along with a diagnostic message — is

also stored into the ALARM HISTORY and ALERT HIS-

TORY tables.

• Review the ALERT HISTORY table to view other less crit-

ical events and abnormal conditions which may have

occurred. Compare timing of relevant alerts and alarms.

Checking Display Messages — The first area to

check when troubleshooting the 19XRV is the ICVC display. If

the alarm light is flashing, check the primary and secondary

message lines on the ICVC default screen (Fig. 18). These

messages will indicate where the fault is occurring. These

messages contain the alarm message with a specified code. For

a complete list of possible alarm and alert messages, see

Table 16. This code or state appears with each alarm and alert

message. The ALARM and ALERT HISTORY tables on the

ICVC SERVICE menu also contains a message to further

expand on the fault description. For a complete list of VFD

Fault Code Descriptions and corrective actions, see Table 17.

NOTE: The date format in these tables is MM/DD/YY.

If the alarm light starts to flash while accessing a menu

screen, press the softkey to return to the default screen

to read the alarm message. The STATUS screen can also be ac-

cessed to determine where an alarm exists.

A “C” to the right of a parameter’s value means that there is

a communications fault on that channel.

Checking Temperature Sensors — All tempera-

ture sensors are thermistor-type sensors. This means that the

resistance of the sensor varies with temperature. All sensors

have the same resistance characteristics. If the controls are on,

determine sensor temperature by measuring voltage drop; if the

controls are powered off, determine sensor temperature by

measuring resistance. Compare the readings to the values listed

in Table 18A or 18B.

RESISTANCE CHECK — Turn off the control power and,

from the module, disconnect the terminal plug of the sensor in

question. With a digital ohmmeter, measure sensor resistance

between receptacles as designated by the wiring diagram. The

resistance and corresponding temperature are listed in

Table 18A or 18B. Check the resistance of both wires to

ground. This resistance should be infinite.

VOLTAGE DROP — The voltage drop across any energized

sensor can be measured with a digital voltmeter while the

control is energized. Table 18A or 18B lists the relationship

between temperature and sensor voltage drop (volts dc

measured across the energized sensor). Exercise care when

measuring voltage to prevent damage to the sensor leads,

connector plugs, and modules. Sensors should also be checked

at the sensor plugs. Check the sensor wire at the sensor for

5 vdc if the control is powered on.

CHECK SENSOR ACCURACY — Place the sensor in a

medium of known temperature and compare that temperature

to the measured reading. The thermometer used to determine

the temperature of the medium should be of laboratory quality

with 0.5 F (.25 C) graduations. The sensor in question should

be accurate to within 2 F (1.2 C).

See Fig. 12 for sensor locations. The sensors are immersed

directly in the refrigerant or water circuits. The wiring at each

sensor is easily disconnected by unlatching the connector.

These connectors allow only one-way connection to the sensor.

When installing a new sensor, apply a pipe sealant or thread

sealant to the sensor threads.

DUAL TEMPERATURE SENSORS — For servicing con-

venience, there are 2 sensors each on the bearing and motor

temperature sensors. If one of the sensors is damaged, the other

can be used by simply moving a wire. The number 2 terminal

in the sensor terminal box is the common line. To use the

second sensor, move the wire from the number 1 position to the

number 3 position.

Checking Pressure Transducers — There are 6

factory-installed pressure transducers, with inputs available for

optional cooler and condenser waterside differential pressure

transducers. The ICVC software will display a default reading

of 26 psi during start-up and operation. An additional transduc-

er, factory installed in the bottom of the cooler barrel, will read

as EVAPORATOR SATURATION TEMP on the HEAT_EX

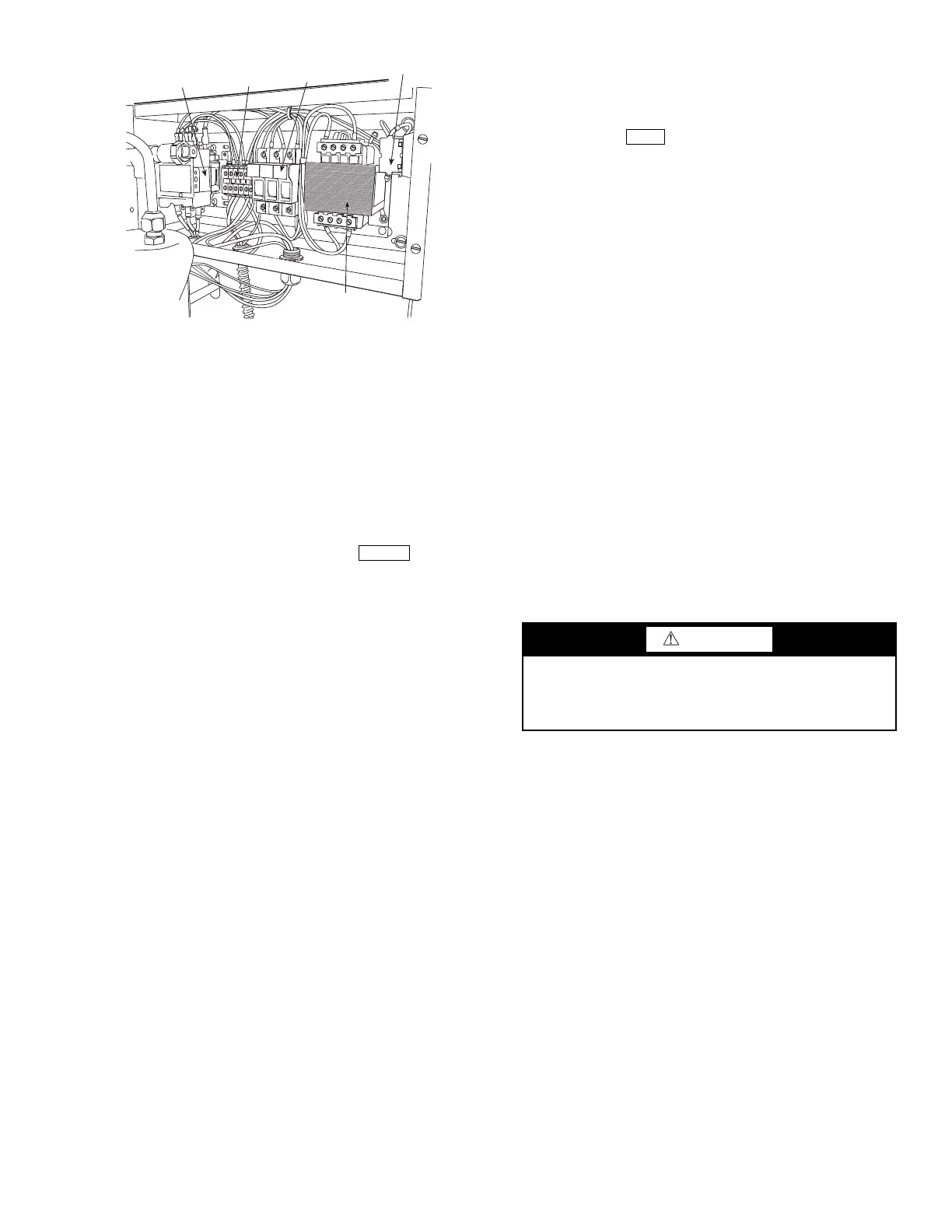

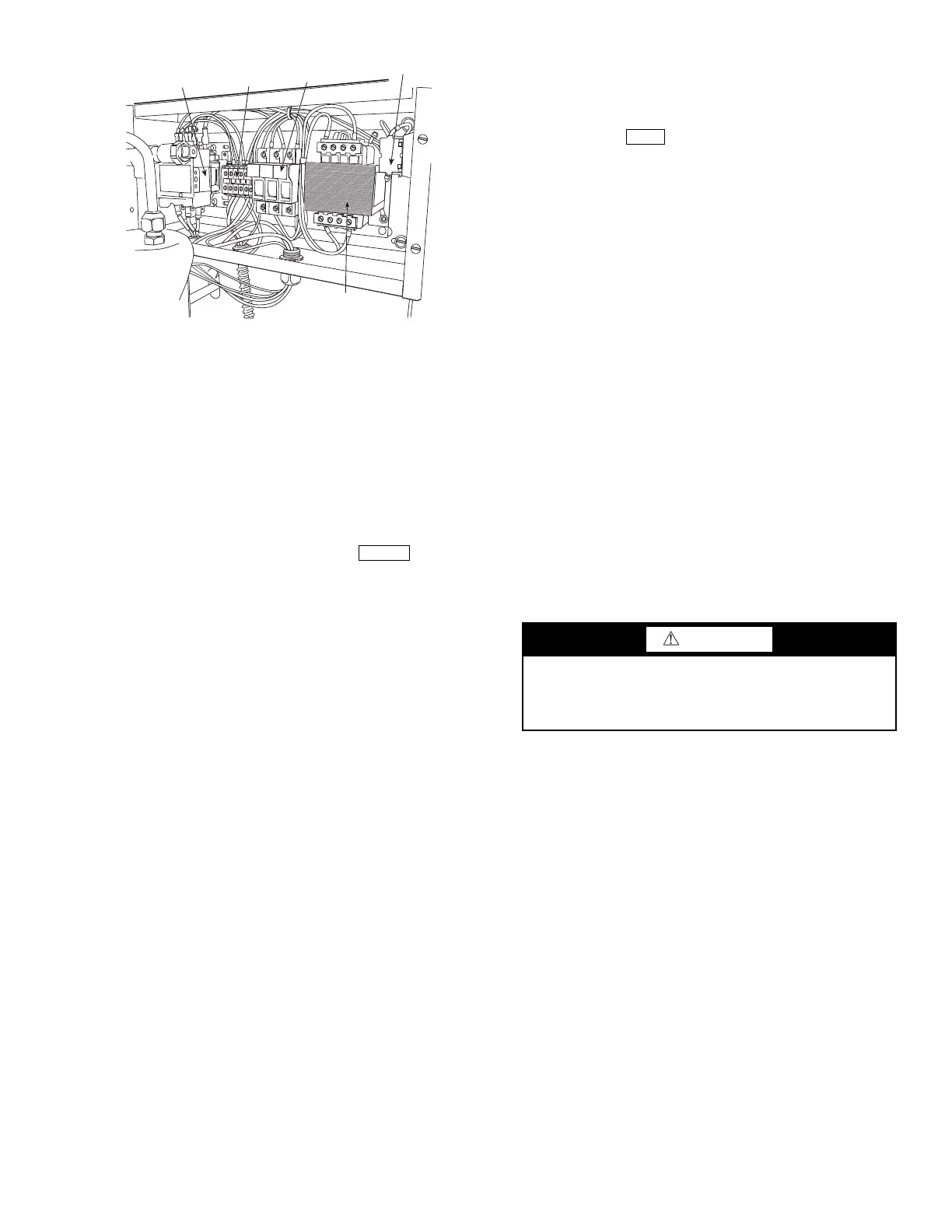

CONTACTOR

TERMINAL

STRIP

FUSES

TRANSFORMER

SWITCH

Fig. 54 — Pumpout Control Box (Interior)

a19-1569

CAUTION

Relieve all refrigerant pressure or drain the water before

replacing temperature sensors or thermowells threaded into

the refrigerant pressure boundary. Failure to do so could

result in personal injury and equipment damage.

Loading...

Loading...