14. For pumped return systems, follow condensate pump or boiler feed pump manufacturer’s instructions for proper installation and hookup.

15. In connecting cold water supply to water inlet valve, make sure that a clean water supply is available. When water supply is from a well

or pump, a sand strainer should be installed at pump.

PROCEDURE 1—FOR USE WITH COOLING UNITS

1. This boiler, when used in connection with chilled water systems, must be installed so that chilled water is piped in parallel with the heating

boiler. Appropriate valves must be used to prevent chilled water from entering the heating boiler. (See Fig. 6.)

2. When this boiler is connected to heating coils located in air handling units where they may be exposed to refrigerated air circulation, piping

system shall be equipped with flow control valves or other automatic means to prevent gravity circulation of boiler water during cooling

cycles.

CHIMNEY AND VENT PIPE CONNECTION

For boilers connected to gas vents or chimneys, vent installations shall be in accordance with Part 7 NFGC, Venting of Equipment and applicable

provisions of local building codes.

PROCEDURE 1—CHECKING CHIMNEY

This is a very important part of the heating system. It must be clean, the right size, properly constructed, and in GOOD CONDITION. No boiler

can function properly with a bad chimney. Inspect chimney and verify that construction and size of chimney meet all applicable provisions of the

NFGC and local building codes. Fig. 7 gives an idea how a boiler might be vented to a chimney. Note that height (HT) is measured from vent

pipe to top.

PROCEDURE 2—CHIMNEY SIZING

Chimney sizing and all other aspects of vent installation must be in accordance with Part 7, NFGC Venting of Equipment and applicable provisions

of local building codes.

PROCEDURE 3—CONNECTING VENT DAMPER AND VENT CONNECTOR

Refer to Fig. 1 flue diagram for size and location of vent (flue opening). Use 28 gauge (minimum) galvanized pipe to connect to chimney.

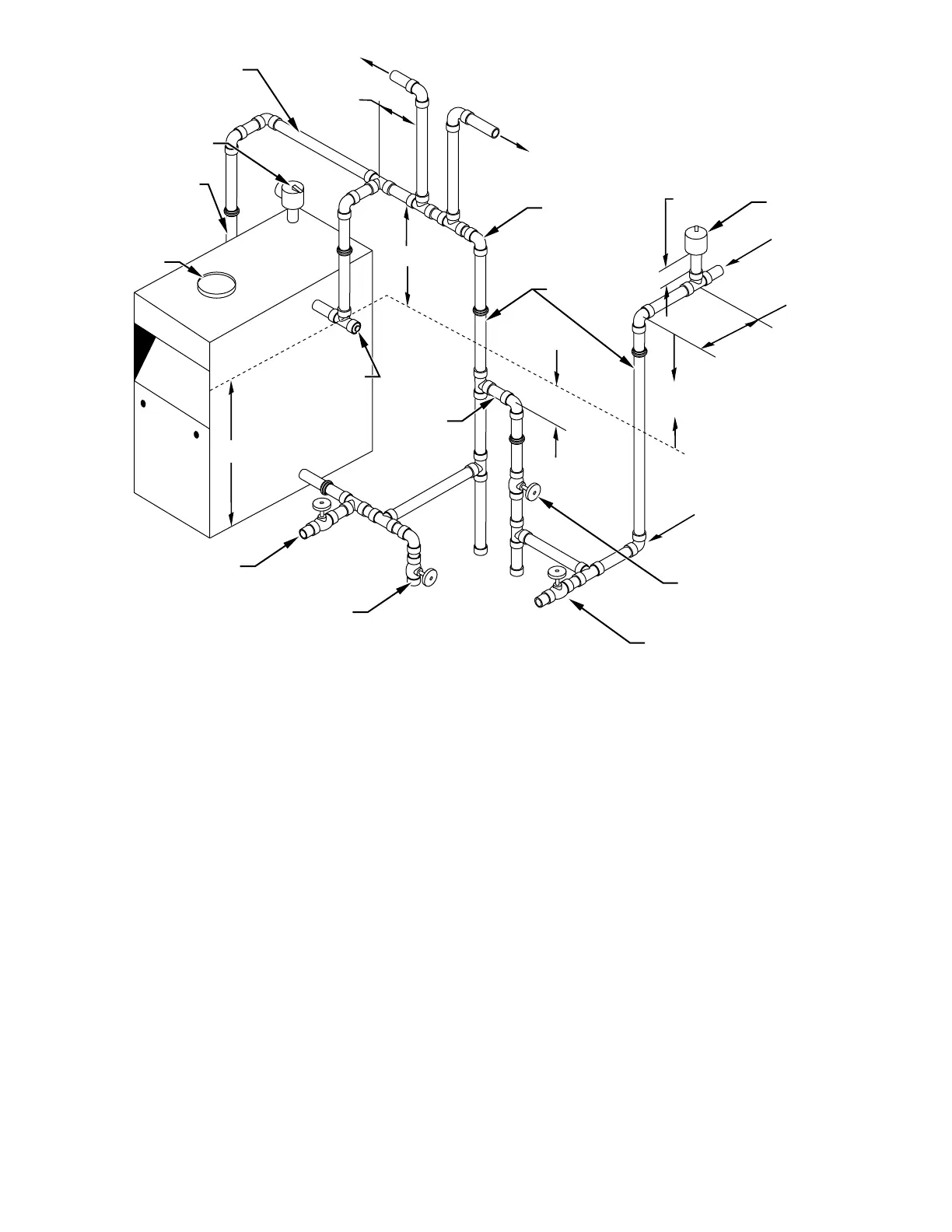

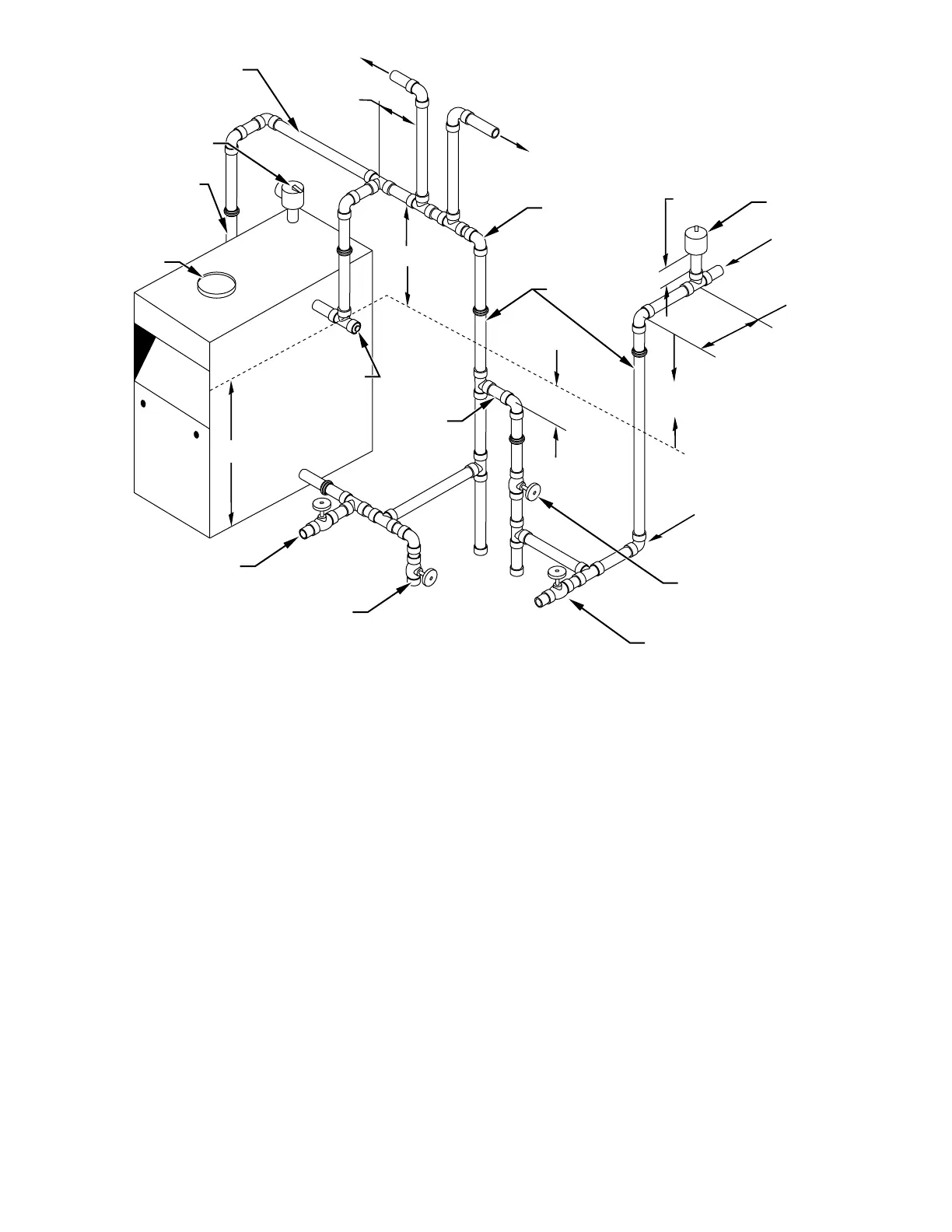

Fig. 4—Recommended Near Boiler Piping Using 2 Supply Tappings

A95494

PIPE FULL SIZE SAME

AS BOILER TAPPING

(2 1/2")

FLUE COLLAR

POP SAFETY VALVE

STEAM

MAINS

MAIN VENT

REDUCING ELL

POINTING DOWN

WATER FEED

GATE VALVE

(NOT FURNISED)

DRY

RETURN MAIN

WET RETURN

DRAIN VALVE (FURNISHED)

FOR FLUSHING SYSTEM

CLOSE

NIPPLE

15″ MIN.

6″

28″ MIN. - DIMENSION A

15″ MIN.

6″ TO 10″

24″ MIN.

1

1

/2″ MIN.

PIPE SIZE

1

1

/2″ FULL PORT BALL VALVE

FOR BOTTOM BLOW DOWN

AND DRAINING BOILER &

SYSTEM (NOT FURNISHED)

WATER LINE

24″

2

1

/2″ TEE

WITH PLUG

FOR SKIMMING

CONNECT RISER TO

BOILER WITH 2

1

/2″

ELBOW AND NIPPLE

(NOT SHOWN)

—8—

Loading...

Loading...