9

669224-R5

2.4 Custom Arm

Installation

Attachments without arms are supplied with two arm

bases. Special forks can be welded directly to them or

they can be used as a base to fabricate custom built arms.

WARNING: Cascade requires that a

qualified or certified welder experienced

in this type of fabrication be used for best

quality.

CAUTION: Weld fabricated arms to the arm bases only.

Do not weld or bolt special built arms or forks directly to

the arm bars.

The arm base material is AISI C-1020 HR with the following

specifications:

• TENSILE STRENGTH – 61,000 PSI (420 mPa) Minimum

• YIELD STRENGTH – 43,000 PSI (300 mPa) Minimum

• CARBON CONTENT – 23% Maximum

CAUTION: The surface flatness of the arm base must

remain within 0.10 in. (.25 mm) in capscrew area and arm

must slide manually.

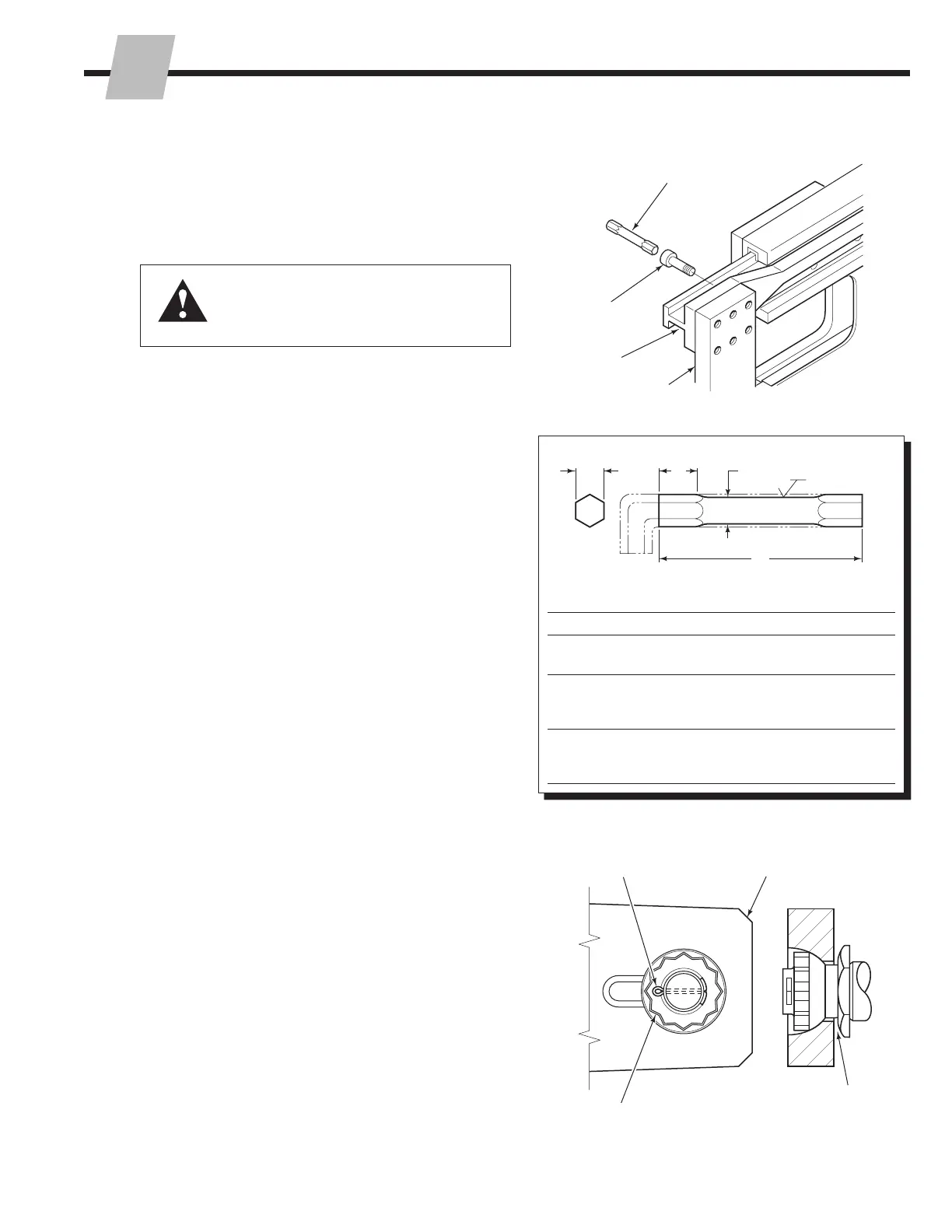

1 Fasten the arm bases to the arm bars. Tighten the

capscrews to the torque values indicated below

with a drive extension tool, 668020 (25D), 667699

(35D,40D,50D) or 676218 (70D,80D, 100D) to tighten

capscrews to the following torque values:

25D – 190–220 ft.-lbs. (257–298 Nm)

35D, 40D, 50D – 280–320 ft.-lbs. (380-434 Nm)

70D, 80D, 100D – 680–720 ft.-lbs. (922-976 Nm)

IMPORTANT: Be careful not to damage the arm bar.

Premature bearing failure will occur.

Short adapters care commercially available:

Williams .50 in. drive to .625 in. hex (25D) and .50

in. drive to .625 in. hex (35D, 40D, 50D) and .75 in.

drive to .75 in. hex (70D, 80D, 100D). Drive extension

dimensions are provided to make the tool from the allen

wrench. Do no use mild steel hex stock.

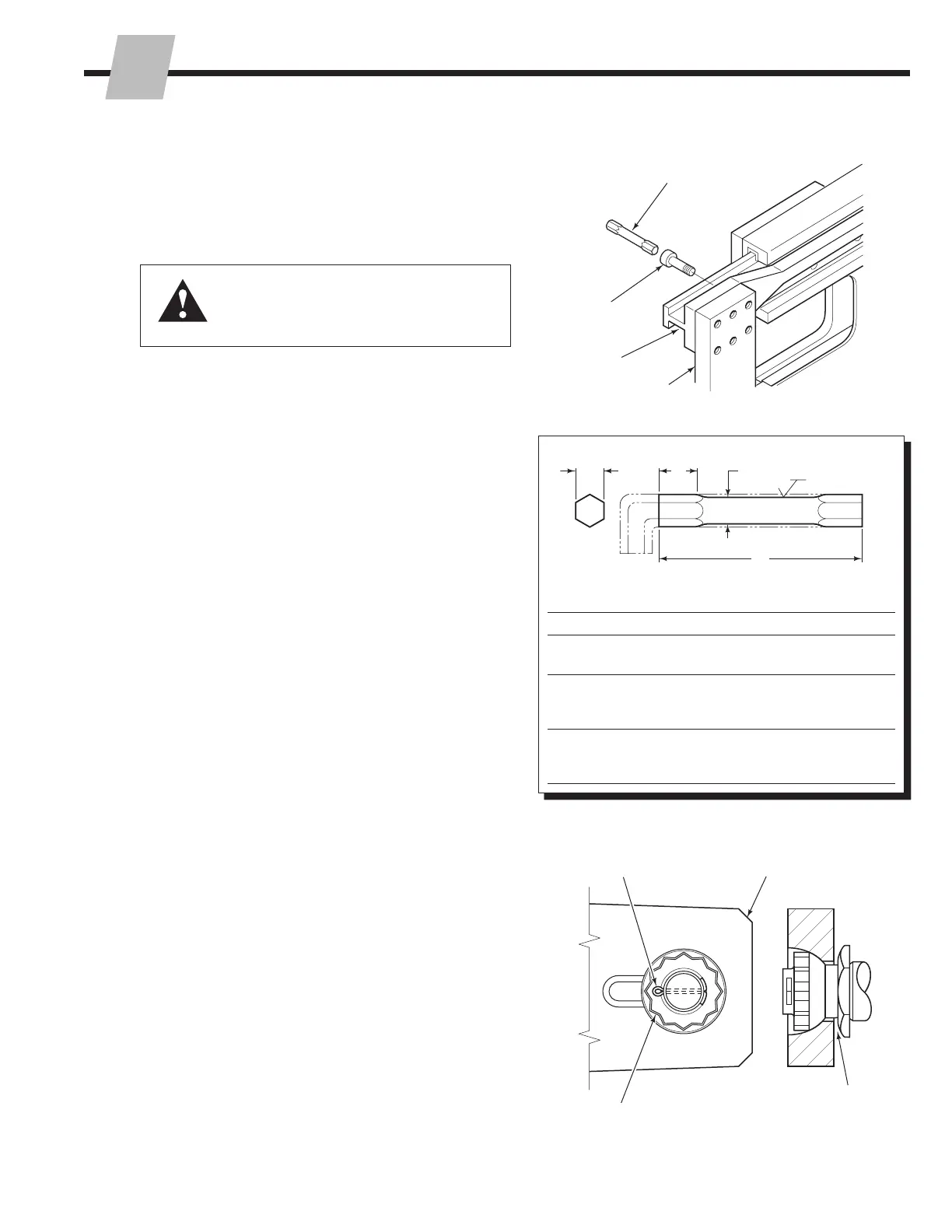

2 Lubricate the cylinder rod threads, nut threads and

spherical portion of the nut with wheel bearing grease.

3 Install the hex washer on the rod end with the beveled

side facing the lug.

4 Engage the rod end into the lug.

5 Tighten the rod end nut to the following torque values:

25D, 30D, 40D, 50D – 150–175 ft.-lbs. (203-–237 Nm)

70D, 80D, 100D – 225–250 ft.-lbs. (305–340 Nm)

Prevent rod turning by using wrench on hex washer.

NOTE: The rod nut is being tightened against the hex

washer. The nut will not be tight against the arm base

lug. This looseness allows for cylinder alignment during

clamping.

6 Install the locking cap and cotter pin.

7 Lubricate the bearing portion of the arm bars with a thin

film of chassis grease, if permitted by your application.

CL0457.ai

Drive Extension

Arm Bar

Arm Base

CL4232.ai

Arm Base Lug

Hex washers beveled

side facing lug

1

3

5

6

NSTALLATION

I

CL0456.eps

A

Hex

B

C

D

63

Dimensions – in. (mm)

Model A B C D

25D

.50

(12.7)

.75

(19.0)

.46

(11.6)

3.50

(88.0)

35D

40D

50D

.62

(15.7)

.50

(12.7)

.58

(14.7)

3.50

(88.0)

70D

80D

100D

.75

(19.0)

.50

(12.7)

.75

(19.0)

5.00

(127.0)

Loading...

Loading...