669224-R5

36

ERVICE

S

5.6-3 Check Valve Service –

Top Mount Valves

IMPORTANT: Service the check valve in a clean work

area.

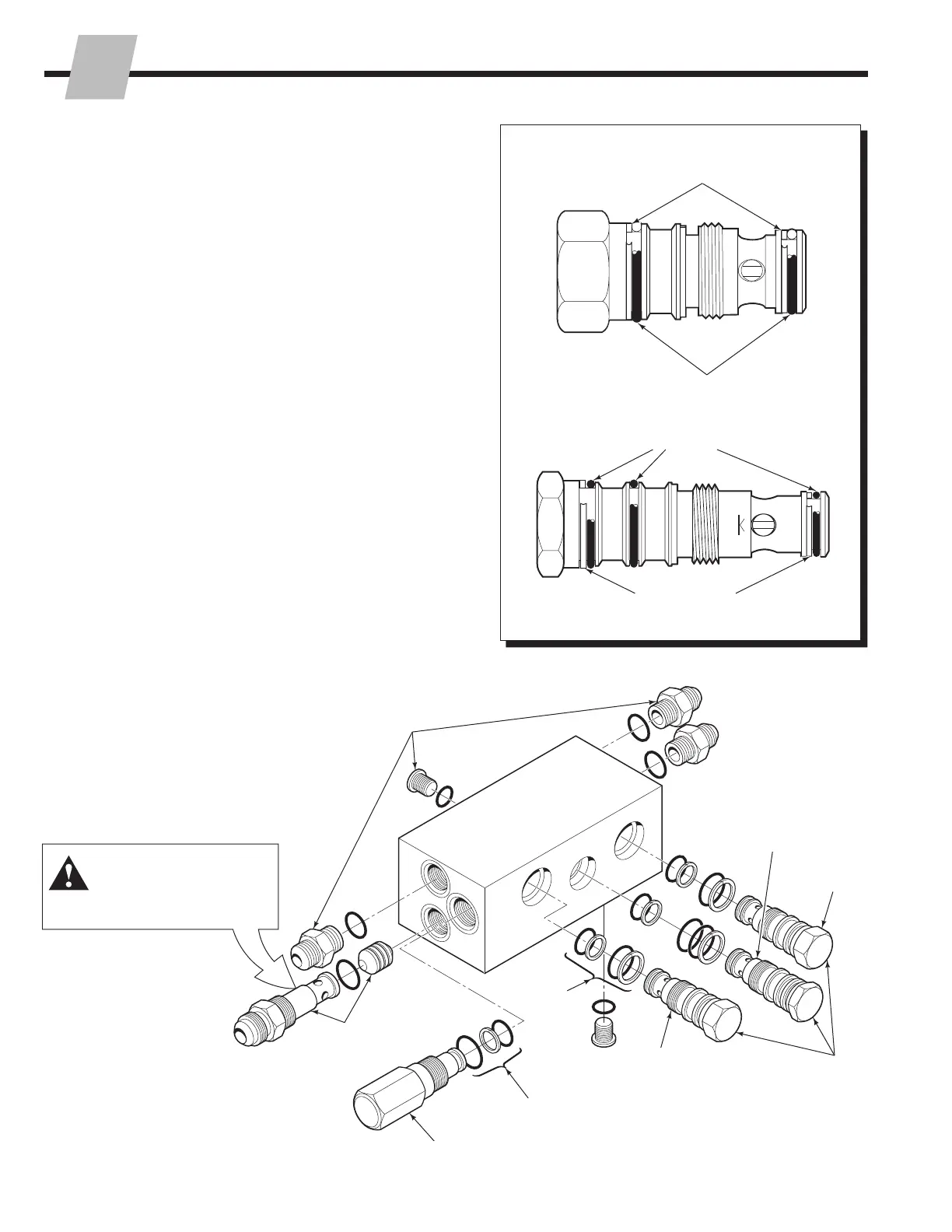

1 Remove the cartridge valves. The non-sideshifting

check valve has one cartridge valve, the sideshift check

valve has three cartridge valves.

2 Remove the special fitting and spool.

3 Remove the remaining plugs and fittings.

4 Remove the O-rings and back-up rings from the

cartridge valve, fittings and plugs.

5 Clean all parts with cleaning solvent.

6 For reassembly, reverse the above procedures except

as follows:

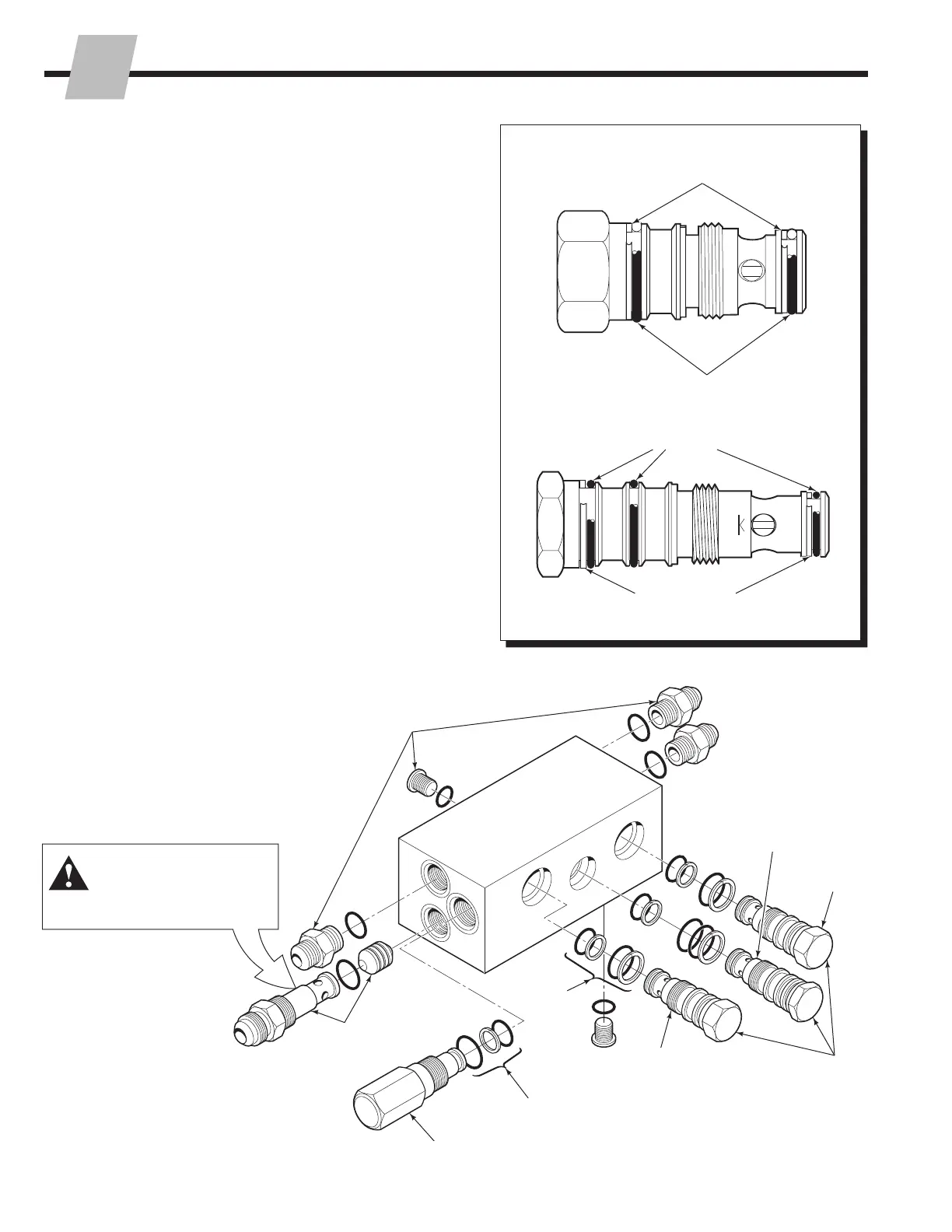

• The cartridge valve back-up rings and O-rings must

be installed as shown to avoid seal damage during

reassembly.

• Lubricate cartridges and seals with petroleum jelly

prior ti reassembly.

NOTE: The 40D non-sideshifting check valve configuration

differs slightly from the illustration below.

CL1011.eps

Sideshift Cartridge

Clamp Cartridge

O-Ring

O-Ring

Back-Up Ring

Back-Up Ring

OP

CL

CL4422.eps

WARNING: The special fitting

must be reinstalled to the clamp

(CL) port. The clamp arms will

not function properly without the

special fitting installed.

3

2

1

1

4

4

Clamp

Cartridge

Valve

Sideshift Right

Cartridge Valve

Sideshift Left

Cartridge Valve

40D Turnafork

Pressure Relief

Valve

CL1429.eps

Loading...

Loading...