11

669224-R5

ERIODIC MAINTENANCE

P

3.1 100-Hour Maintenance

Every time the lift truck is serviced or every 100 hours

of truck operation, whichever comes first, complete the

following maintenance procedure:

• Inspect the cylinder anchor joint for lubrication and

correct hold.

NOTE: Anchor joint operates with a loose clearance.

Lubricate with wheel bearing grease.

• Arm bearing life can be extended by a light application

of chassis grease, if permitted by your application.

• Tighten arm capscrews to the following torque value:

25D – 190–220 ft.-lbs. (257–298 Nm)

35D, 40D, 50D – 280–320 ft.-lbs. (280–434 Nm)

70D, 80D, 100D – 680–720 ft.-lbs. (922–976 Nm)

3.2 500-Hour Maintenance

After each 500 hours of truck operation, in addition to the

100-hour maintenance, perform the following procedures:

• Check the lower mounting hook engagement clearance

with the truck carriage bar:

Quick-Change Hooks – 3/32 in. (2.5 mm) minimum

3/16 in. (5.0 mm) maximum

Bolt-On Hooks – Tight against lower carriage bar

If adjustment is necessary, refer to Installation Step 6.

Tighten the lower hook capscrews as follows:

Class II/III Mounting – 110 ft.-lbs. (150 Nm)

Class IV Mounting – 190 ft.-lbs. (260 Nm)

• 70D, 80D, 100D Clamps – Tighten the upper hook

capscrews to 210 ft.-lbs. (285 Nm).

• Check clamp force. Cascade Clamp Force Indicators

35G-DFI-8RF and 35G-CFI-8RF are available for this test.

3.3 1000-Hour Maintenance

After each 1000 hours of truck operation, in addition to

the 100 and 500-hour maintenance, perform the following

procedures:

• Inspect the arm bearings for wear. If any bearing is

worn to less than .040 in. (1 mm) thickness, replace all

bearings. Refer to Service Section 5.2-5.

3.4 2000-Hour Maintenance

After each 2000 hours of truck operation, in addition to

the 100, 500 and 1000-hour maintenance, perform the

following procedures:

• Inspect the arm bearings for wear. If any bearing is

worn to less than .040 in. (1 mm) thickness, replace all

bearings. Refer to Service Section 5.2-5.

• Tighten the frame mounting plate capscrews to the

following torque value:

25D, 35D – 60 ft.-lbs. (85 Nm)

40D, 50D – 110 ft.-lbs. (150 Nm)

70D, 80D, 100D – 190 ft.-lbs. (260 Nm)

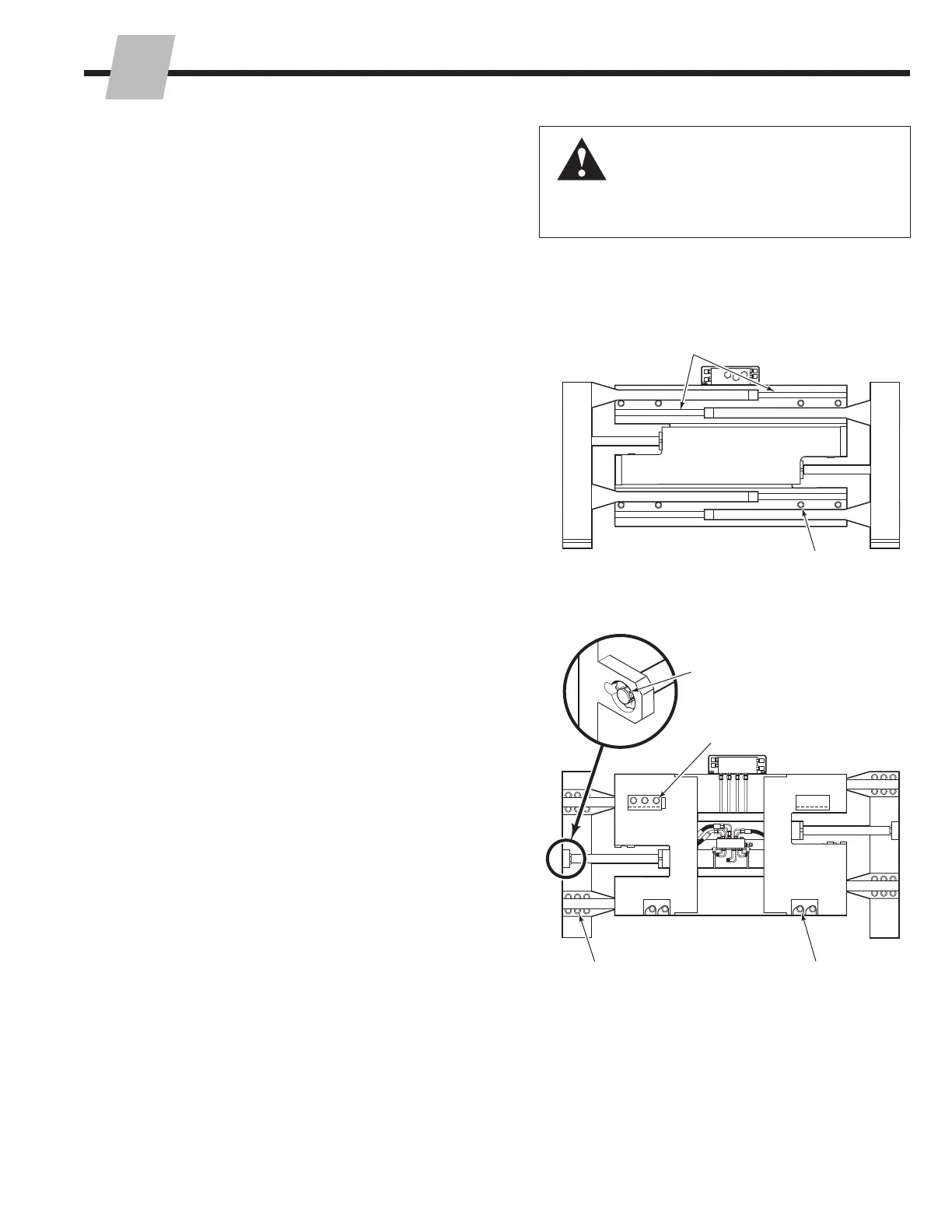

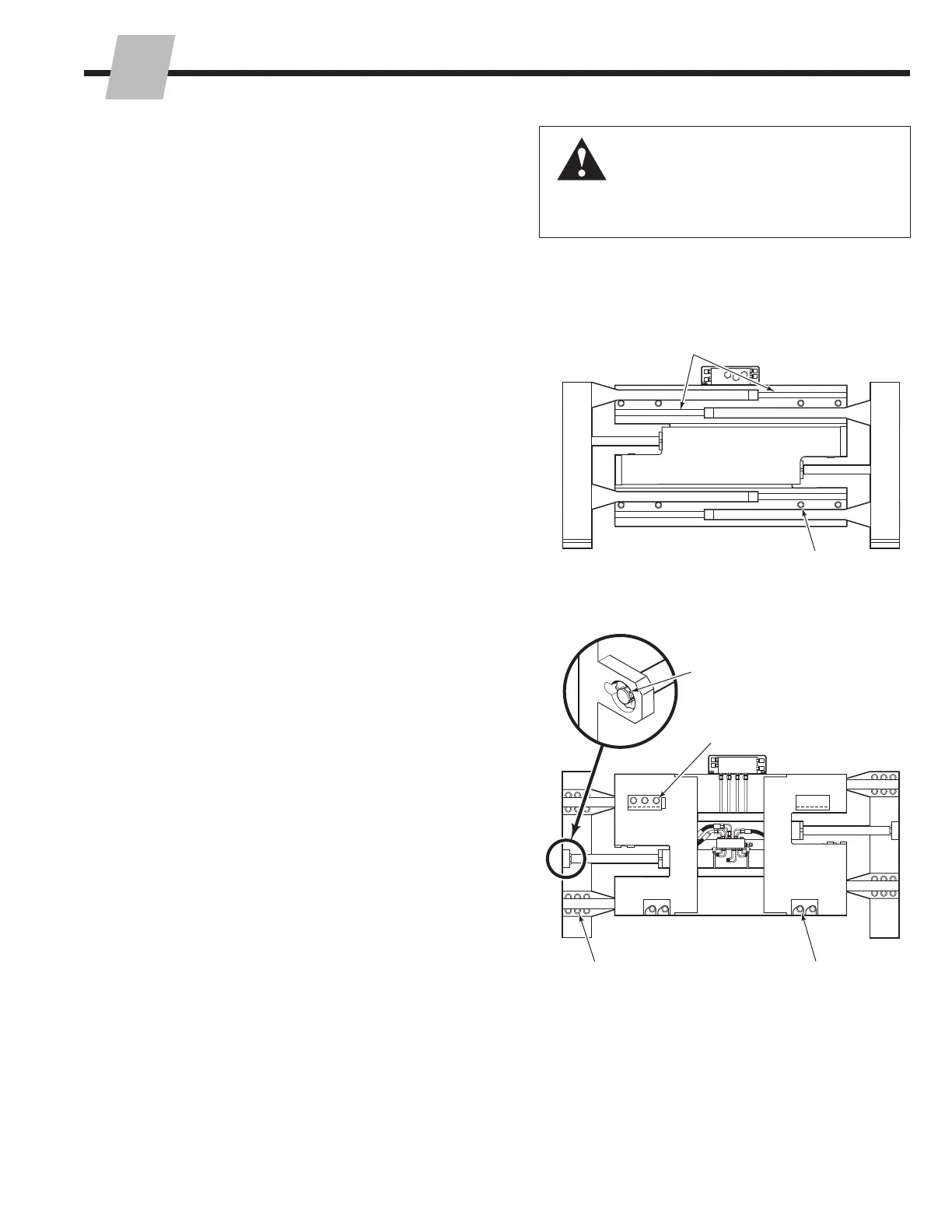

CL1398.ai

Arm Bearings

Frame Mounting

Plate Capscrews

Cylinder Anchor Joint

70D, 80D Upper

Hook Capscrews

Arm Capscrews Lower Hook Capscrews

Front View

Back (Driver's) View

WARNING: After completing any service

procedure, always test the clamp through

five complete cycles. First test the clamp

empty, then test with a load to make sure

the attachment operates correctly before

returning to the job.

Loading...

Loading...