15

6095756-R2 EN

PERIODIC MAINTENANCE

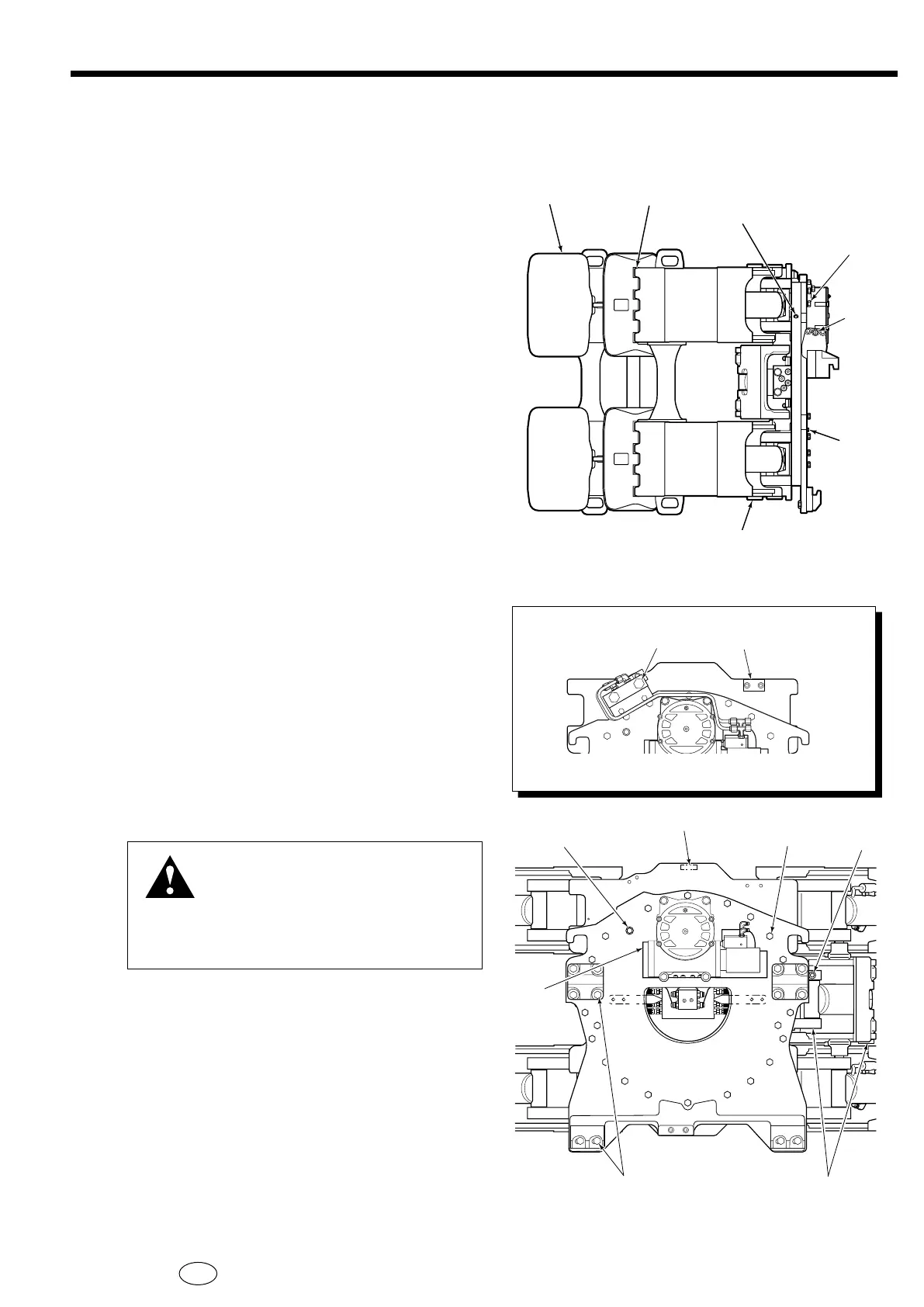

RC4854.eps

NOTE: If swing components require service, refer to

H-Series Swing Frame Paper Roll Clamp Service Manual

Supplement 6844788. If arms, clamp cylinders and rotation

related components require service, refer to H-Series

Fixed Frame Pivot Arm Paper Roll Clamp Service Manual

6078255.

Daily

Check items shown each day. Report problems to your

supervisor. See Service Manual for troubleshooting,

maintenance and repair procedures.

• Check for loose or missing bolts, worn or damaged

hoses, and hydraulic leaks.

• Check the edges of the contact pads for wear or sharp

nicks that could damage or tear paper rolls. Grind the

edges smooth.

• Check the contact pad pivot joints for wear. Repair or

replace as necessary.

• Check that load handling hydraulic system is

functioning properly. Clamp Force Indicators 830141,

832442 and 200645 are available for this test.

• Check decals and nameplate for legibility.

1000-Hour Maintenance

After each 1000 hours of truck operation, in addition to

the daily Inspection, perform the following maintenance

procedures:

• Check the torque on the stop block capscrews. Tighten

to 110 Nm, if necessary.

• Check sample of baseplate capscrews for proper

torque value. See Technical Bulletin TB183 for checking

and replacement procedures.

• Check sample of bearing capscrews for proper torque

value. See Technical Bulletin TB183 for checking and

replacement procedures.

• Tighten mounting hook capscrews:

Class II/III – 165 Nm

Class IV – 265 Nm

• Tighten rotator drive capscrews to 88 Nm.

• Lubricate rotator bearing assembly with EP-2 grease

(Whitmore 'Omnitask' or equivalent). Rotate clamp in

90 degree increments and grease in each position.

• Check rotator drive gearcase lubricant level.

Lubricant should be up to bottom of fill plug hole.

If necessary, fill with Cascade Rotator Drive Lubricant,

Part No. 656300, or SAE 90 wt. gear lube (AGMA

'mild' 6 EP Gear Oil). Replace plug.

WARNING: A sampling of faceplate and

baseplate bearing assembly capscrews

must be check for proper torque at 1000

hours (see TB183), and all capscrews

checked at every 2000 hours. Failure to

keep the capscrews tightened can result

in attachment damage and serious injury.

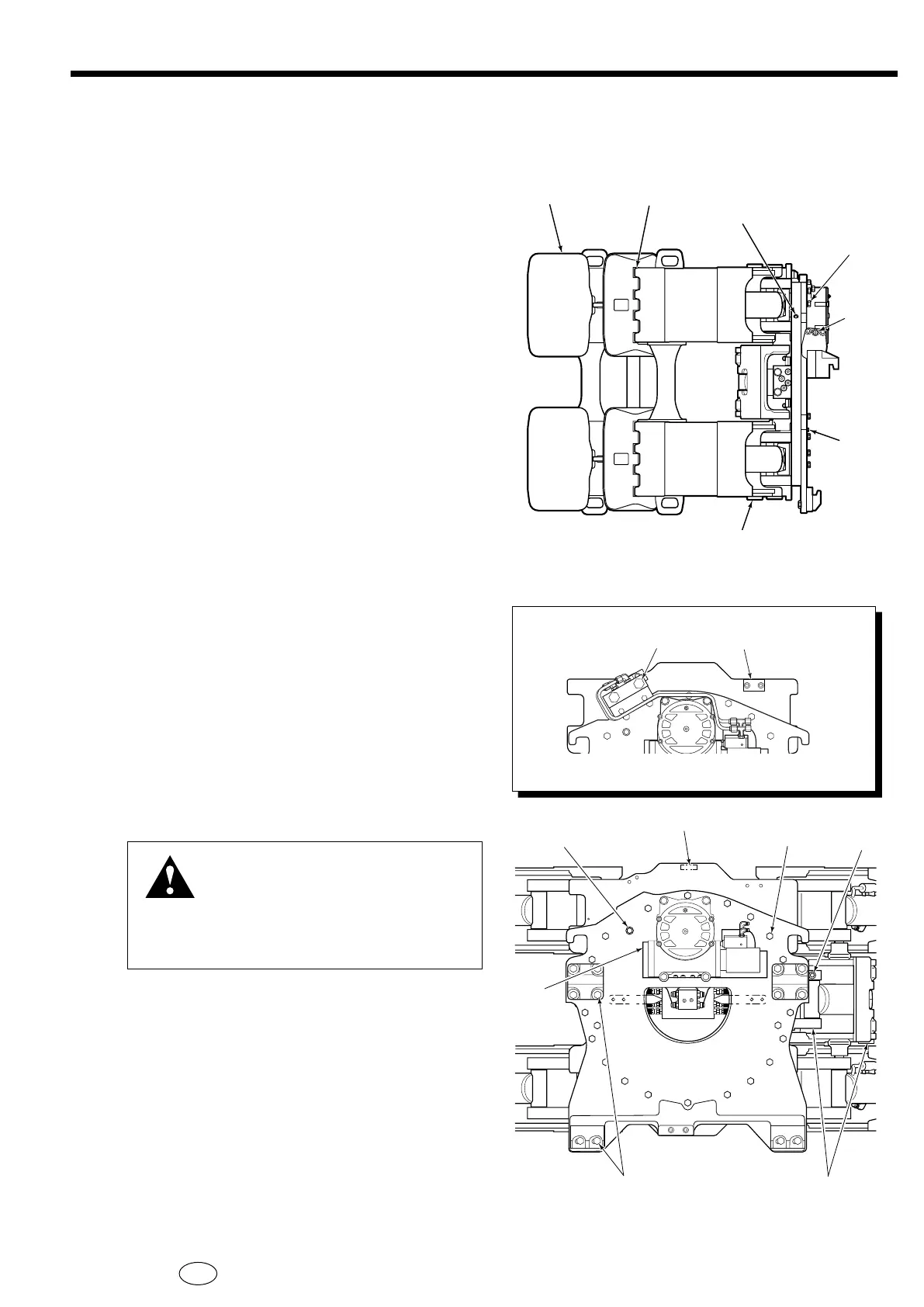

RC3761.eps

Contact Pad

Edges

Contact Pad

Pivot Joints

Rotator Bearing

Assembly

Grease Fitting

Rotator

Drive

Fill Plug

Arm, Cylinder, Swing,

Frame Pivot Points

Pin

Capscrew

Rotator Drive

Capscrews

Baseplate

Capscrews

Swing Frame

Pivot Joints

Baseplate

Capscrews

180-Degree

Stop Valve

Stop Block

Gear

Grease

Fitting

Mounting Hook

Capscrews

Swing Anchor

Pivot Joints

Rotator

Drive Fill

Plug

Right Side

180° Stop Valve Option

Back (Driver's) View

Back (Driver's) View

Loading...

Loading...