INSTALLATION

3

6095756-R2 EN

Swing Control Valve Installation

Follow the steps shown to install a Swing Frame Paper Roll

Clamp. Read and understand all WARNING statements.

If you don't understand a procedure, ask your supervisor

or call the nearest Cascade Service Department for

assistance.

NOTE: Swing Frame Clamps require a solenoid-operated

control valve group to convert a two function auxiliary

control valve to three function operation.

For hose reel information, refer to Installation Instructions

673835 for THINLINE

TM

2-Port Hose Reels and Installation

Instructions 675395 for THINELINE

TM

2-Port Hose Reels (for

masts without internal reeving). Control valve groups for

different voltages are listed in the table shown.

1

2

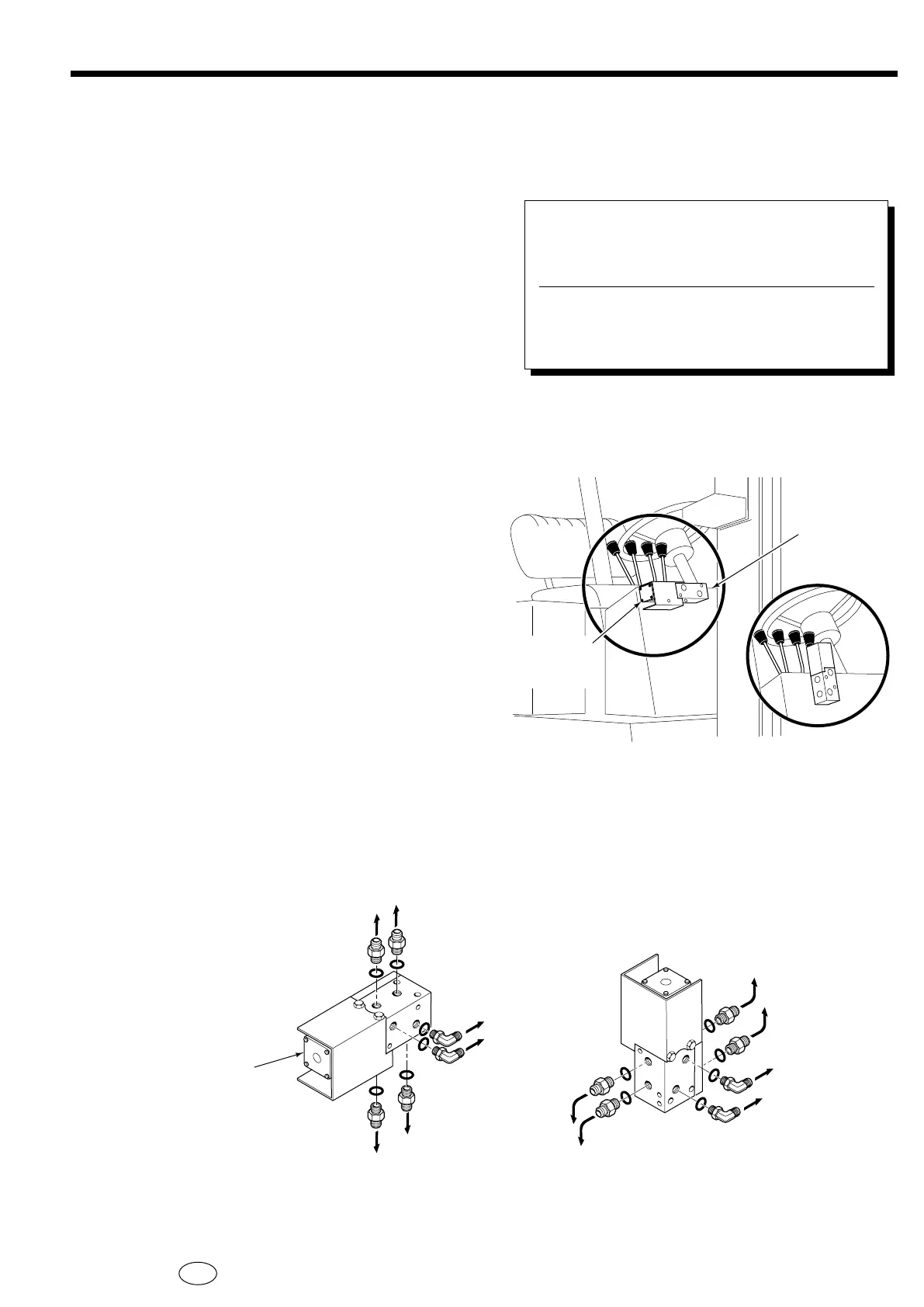

Determine an appropriate mounting location for

the control valve on the truck cowl. The valve can

be mounted horizontally or vertically. The valve

must not extend outside the width of the cowl or

interfere with the truck mast.

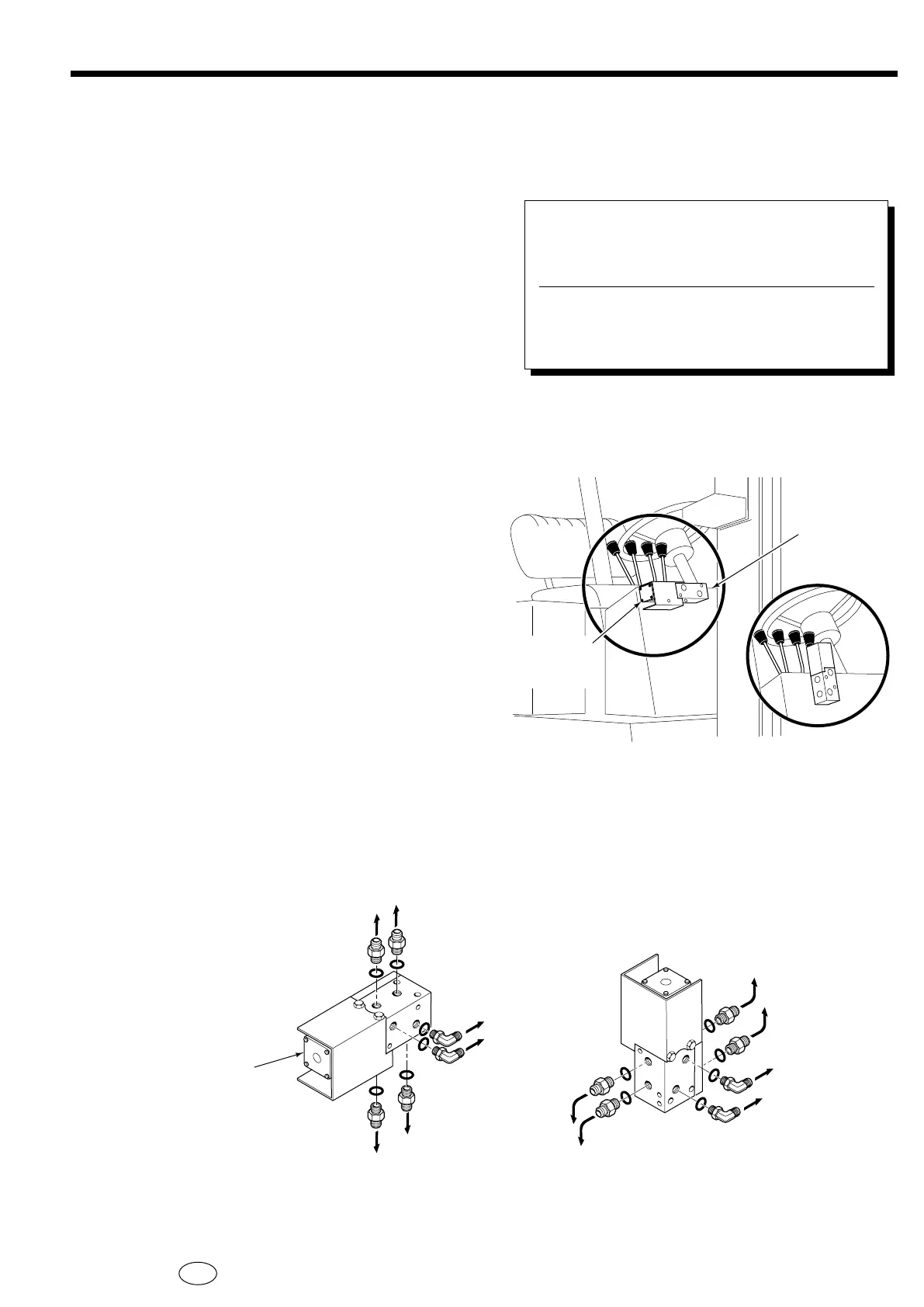

Assemble the solenoid valve, fittings, cover and

subplate. Position the assembly on the truck cowl

noting any clearance problems.

Control Valve Group

With Knob

Part Number

With Low

Profile Switch

Part Number Truck Voltage

674924

674925

674926

674927

6014883

6014885

6014886

6014887

12V

24V

36V

48V

RC0725.eps

HORIZONTAL MOUNT

HORIZONTAL MOUNT

VERTICAL MOUNT

VERTICAL MOUNT

Check for

interference

with mast

tilted back

Valve must not

extend outside

width of cowl

RC0726.eps

To RH 2-Port Hose

Reel (No. 8 SAE)

To RH 2-Port Hose

Reel (No. 8 SAE)

To LH -Port or

2-Port Hose Reel

(No. 6 SAE)

To LH -Port or

2-Port Hose Reel

(No. 6 SAE)

NOTE: Solenoid coil

must be rotated 90

degrees to clear cover

when assembled.

To truck auxiliary

valve ports (No. 8)

To truck auxiliary valve

ports (No. 8 SAE)

Loading...

Loading...