Supplement 8181

c

3

ill

'77

[i.

.ca

uti

,!C

in.

..0

avi

.-.

E

OPERATION

N° MA. 173-0

(/ki t/ t7 Sfif)f)/\ Op. MA.

173-0

4.

1

PETROL

PUMP

AC DELCO

pump reference

E/PE

4.777

-

Auto

regulating diaphragm

lift and

force

pump

operated by

eccentric on camshaft.

This pump is fitted

with a device which enobles

it

to function on re-cycied petrol.

This re-cycling

is

elfected

by means

of a

by-pass

(

1)

fitted on

the

carburettor

cover.

Excess

petrol

supplied by the pump returns to the

tank across

an

orifice calibrated from

0.8 to 0.9mm

in

the by-pass

union (1).

PETROL

PUMP OUTPUT

a)

Oupui

nu, maximum

pressure

325 mbors.

(4

7psi).

b

}

Output

through open carburettor

float needle

valve.

engine

rpm

Minimum

output

ln litres per

hour

Minimum

pressure

in mbars

500

45

88

3000

65

170

5500

69.5

192

INSTALLATION

OF PETROL

PtJMP

Fitted

on

the

crankcase with

-

one

Phenoplaste

P12

»

spacer

6

± 0.1 mm thick.

- two

SOCOID »

puper gaskets

fitted dry.

Tightening

torque for petrol

pump

nuts

21

mN (2.1 m.kg

)

(15

1/4

ft.Ib

CHECKING

THE

STROKE OF

THE

PUMP

PUSH-ROD

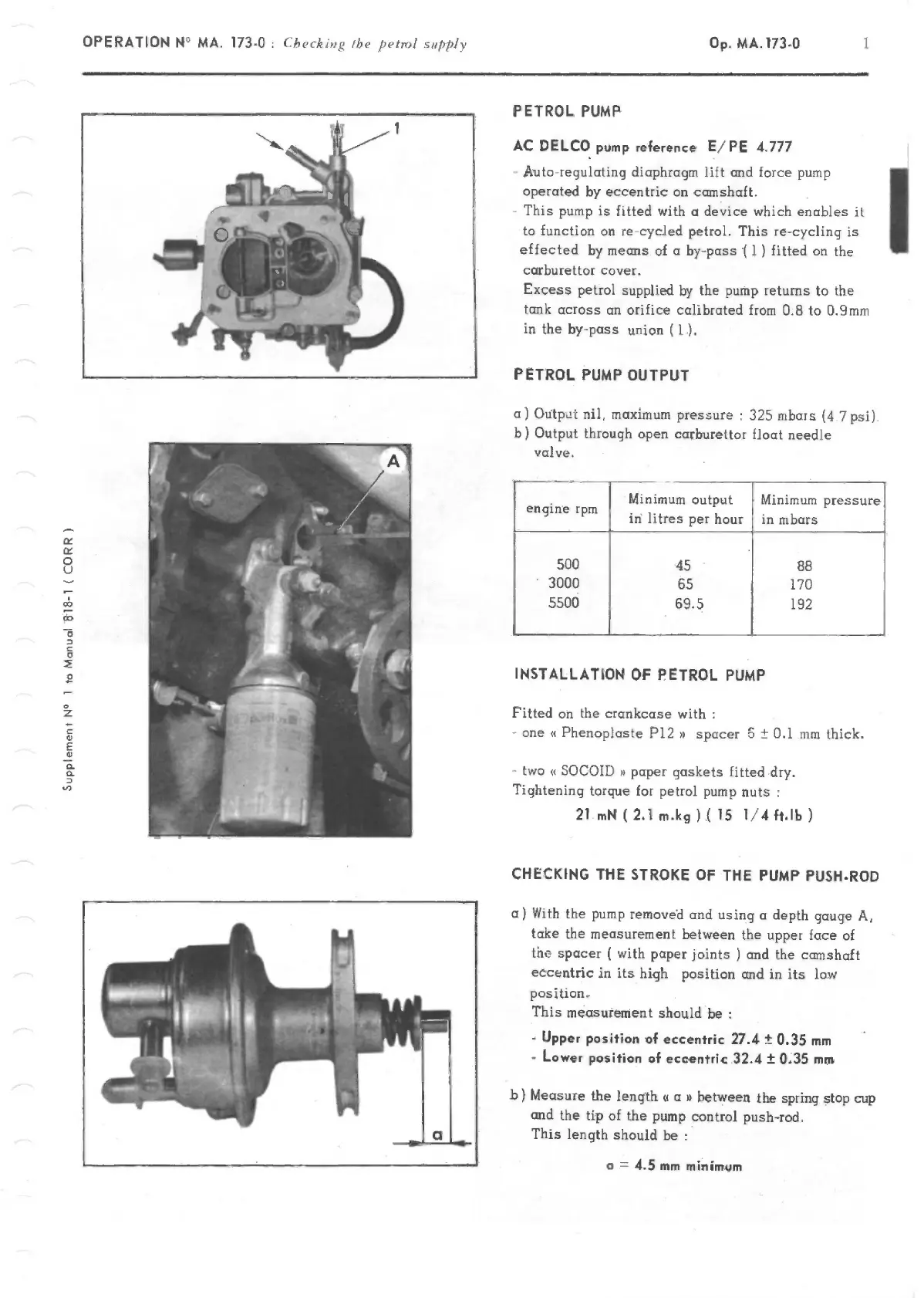

a)

With

the pump

removed and

using a depth

gauge

A,

take the

measurement

between the

upper face

of

thQ spacer

(

with paper

joints

)

and

the

canishaft

eccntric

in its

high

position and in its low

position.

This

measurement

should

be

-

Upper

position

of eccentric

27.4 ±

0.35

mm

-

-

Lower

position

of eccentric

32,4

i

0.35 mm

b)

Measure

the

length

« a »

between

the spring stop cup

and

the

tip of the

pump control

push-rod.

This

length

should be

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Loading...

Loading...