Supplement Manual

818-1

l-.

.'7

p_,

42,

nit

Uti

Cl.

0

OPERATION

N°

MA.

390-0

: (.heck/n fbi' b driiy/ic c ,Pouee/s on the ,tb,cle

Op. MA. 390-0

SI (InUcil S1I (Tfl1 lebiCl(5

1

CHECKINGTIIE HYDRAULIC COMPONENTS

0

u

0

D

0

0

z

c

0

E

0

0.

fr

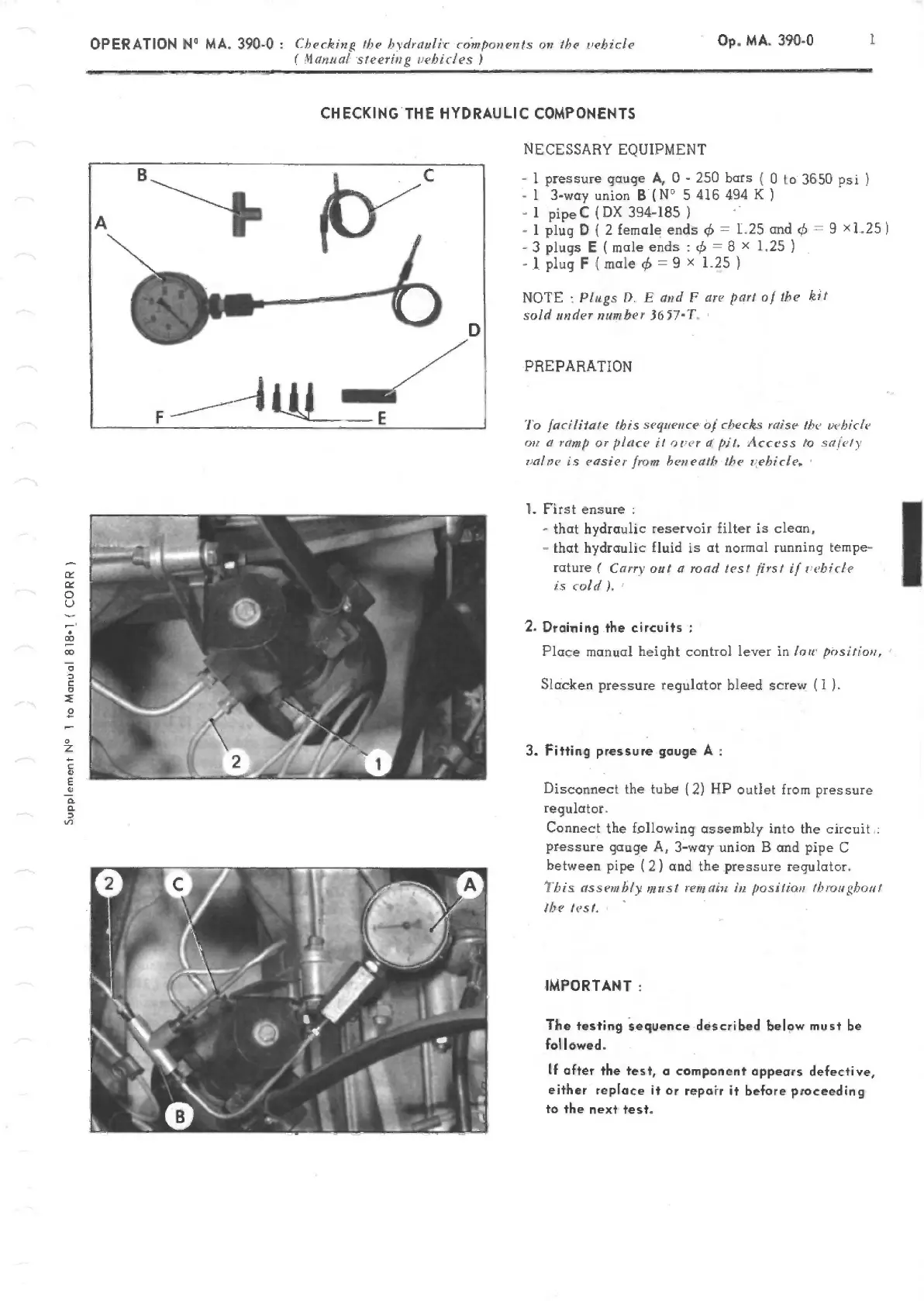

NECESSARY EQUIPMENT

-1 pressure

gauge A, 0-250

bars

(

0 to

3650

pi

-

1 3-way union

B(N0

5416494 K

-

1

pipeC

(DX

394-185

-

1 plug D

{

2

female ends

1.25 and

9 xL25)

-3plugsE(maleends:&=8>

1.25)

-

1 plug

F

(male

9

x

1.25

NOTE

: J'lugs

fl, E and F

are part oj

the

kl!

sold uflder number

36

57'I'.

PREPARATION

'lo facililate this

sequc';lce of checks raise

the iehklc

a ramp

or

place

ii

a

pil.

Access

to

sa/ely

ca/te

is easzer from ben cath tbc

tehicie.

1.

F'irst

ensure

-

that hydraulic reservoir filter is

dean,

-

that

hydraulic

fluid is

at

normal

running

tempe-

rature ( (arr-

out

a

road

test

first

/(

t'ehicfe

is

cold

).

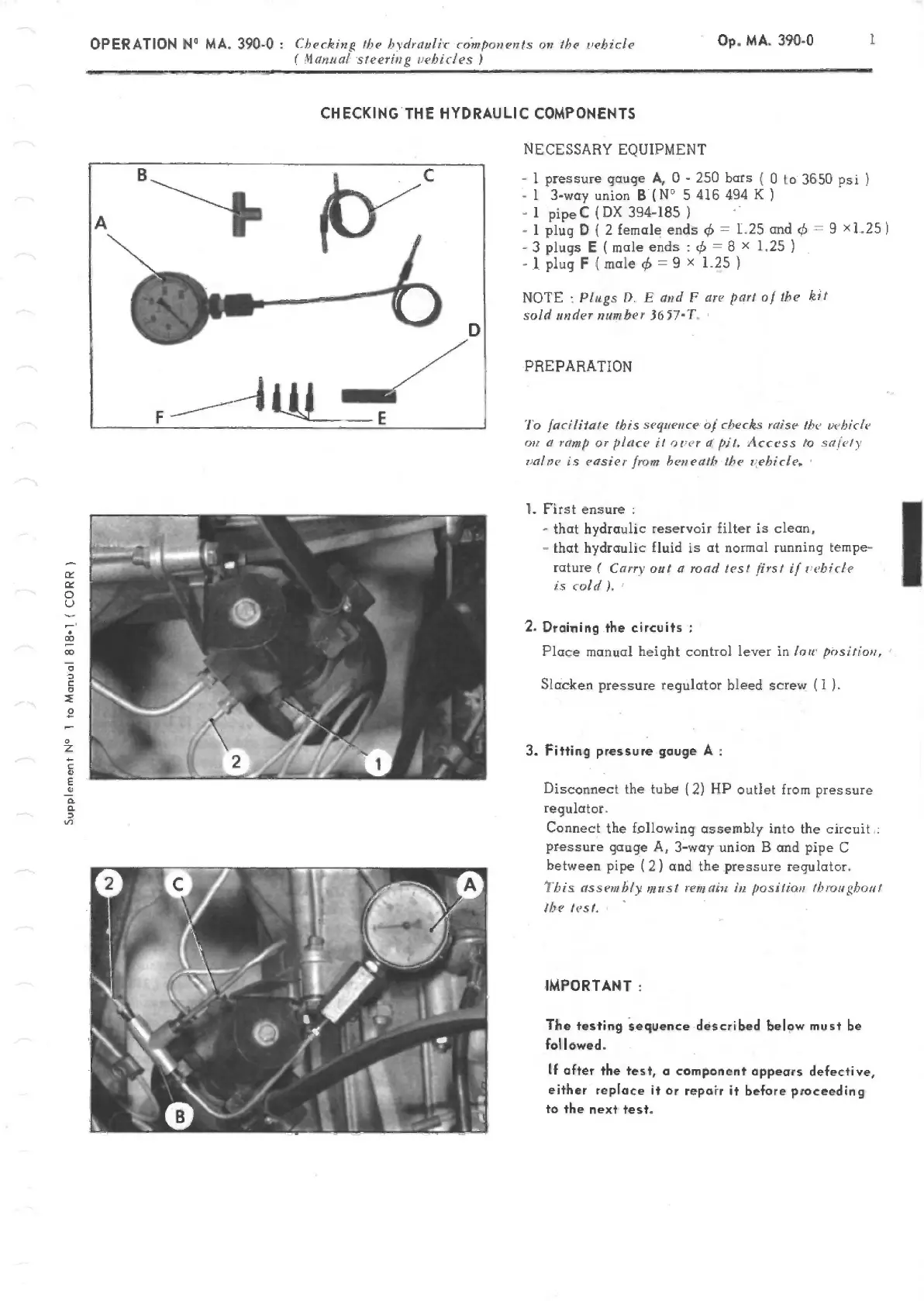

2.

Draining the

circuits

Place manual height

control

lever

in (ou prsitiwi,

Slacken

pressure regulator

bleed

screw

(1

).

3. Fitting pressure gouge

A

Disconnect the tube (2) HP

outlet from pressure

regulator.

Connect

the

following

assembly

into

the

circuit

pressure

gauge A,

3-way union B and pipe

C

between pipe

(2)

and

the pressure regulator.

1 his ass cm

bly mu st

rem alt: in

position

Ibrougbon 1

the

test.

IMPORTANT:

The testing sequene clescribecl below must be

fol

1

owed.

If

after

the

test, a

component

appears

defective,

either

replace it or

repair

it

before proceeding

to

the next test.

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Loading...

Loading...