11

5 - AERAULIC CONNECTIONS

The dimensioning and correct execution of the aeraulic

connections are fundamental to guarantee good unit operation

and adequate level of silence in the room.

When designing and manufacturing the channels, consider

LOAD LOSSES, AIR FLOW AND SPEED that must be

consistent with the unit features.

Particularly consider that load losses higher than the unit

useful prevalence, lead to reduction in flow rate, with

consequent unit blocks.

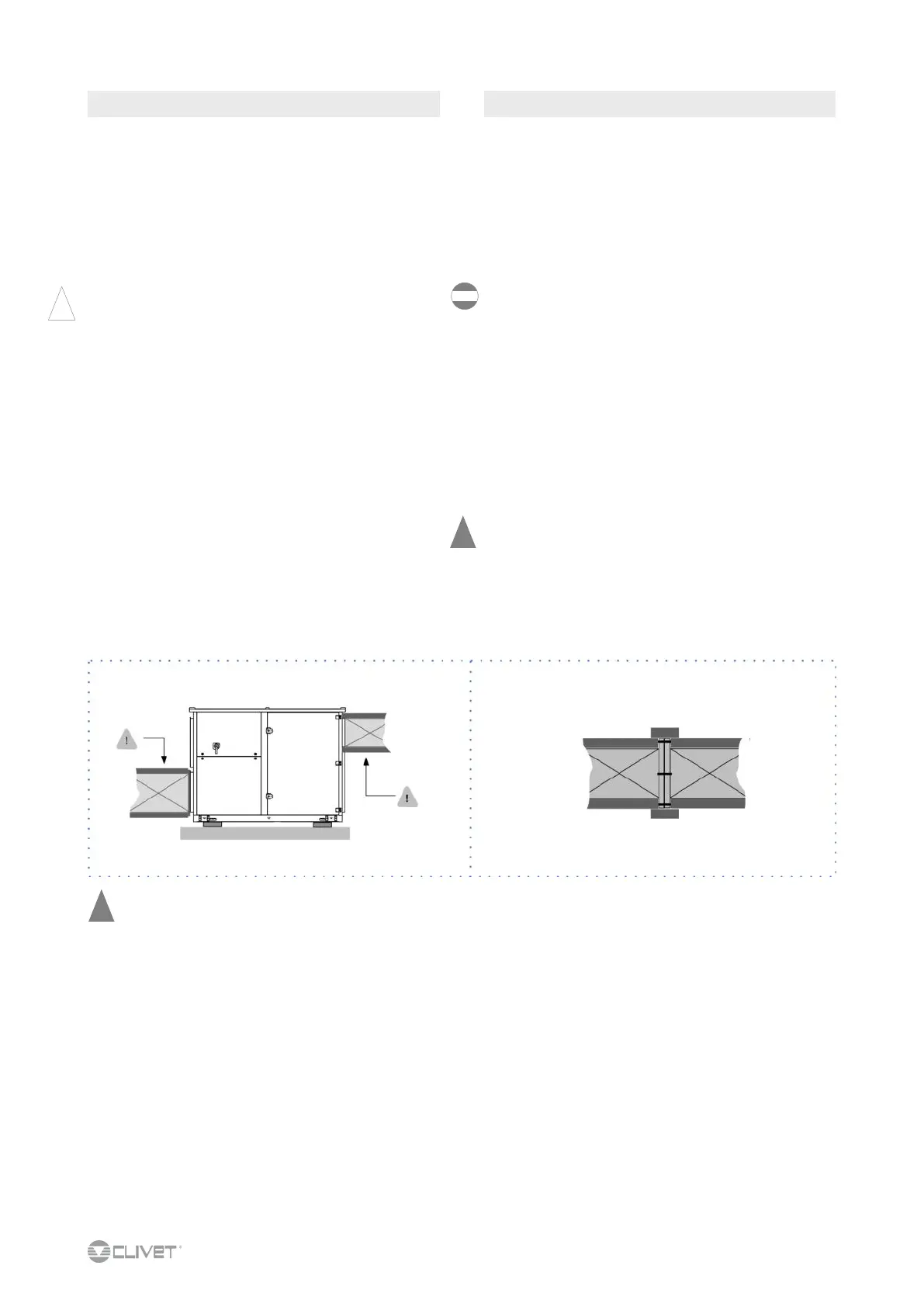

the weight of the channels must not burden on the

connection flanges

place anti-vibration joints between channels and unit

connection to the flanges and between the various

sections of the channels must guarantee air seal, avoiding

dispersions penalising the overall efficiency of the system

limit the load losses by optimising the path, the type and

number of bends and junctions

use wide bends evaluating the opportunity of equipping

them with deflectors (in particular with high air speed or

bends with reduced radius).

5.1 Generality

The internal surface of the channel must be smooth, enable

its washing and must not contaminate the air

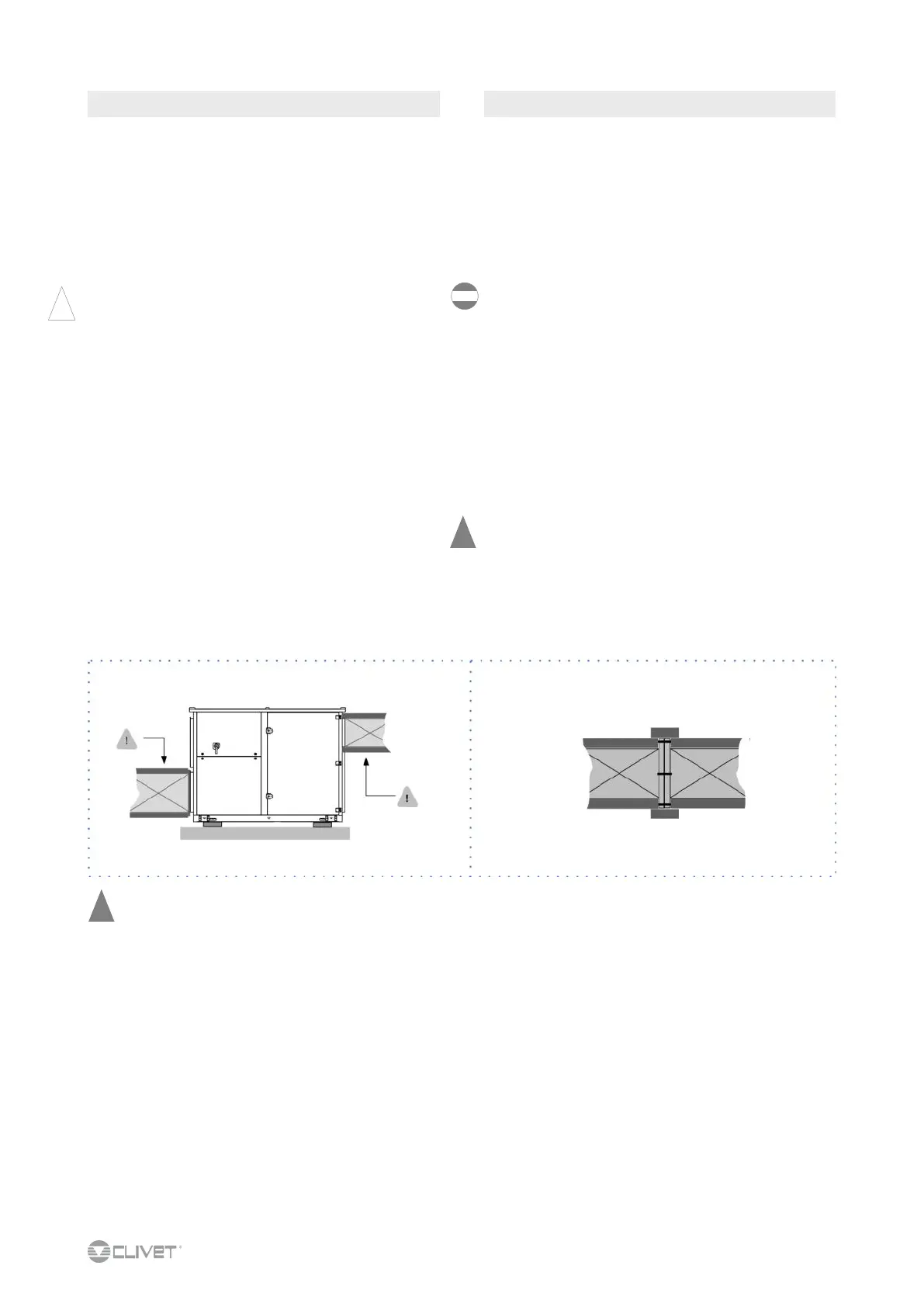

Thermally isolate the channels and the flanges to avoid

energy losses and forming of condensation

DIFFUSERS INLETS GRILLES

A correct diffusion of the air in the room is determining for the

level of comfort.

When choosing and positioning the grilles, inlets and

diffusers, avoid:

excessive air speed

forming of stagnant and stratification areas

cold air delivery in room

forming of localised currents (also due to uneven

distribution of air)

excessive room temperature variations, vertically and

horizontally

short circuits of the supply air towards the return air.

For sound comfort, consider that :

the air diffusers must be chosen verifying the sound power

generated at nominal flow rate conditions

the cut-off to diffusers must be carried out with flexible

elements

the return grilles must be widely dimensioned.

5.2 Treated air channelling

Thermally isolate the channels and the flanges to avoid energy losses and forming of condensation

Loading...

Loading...