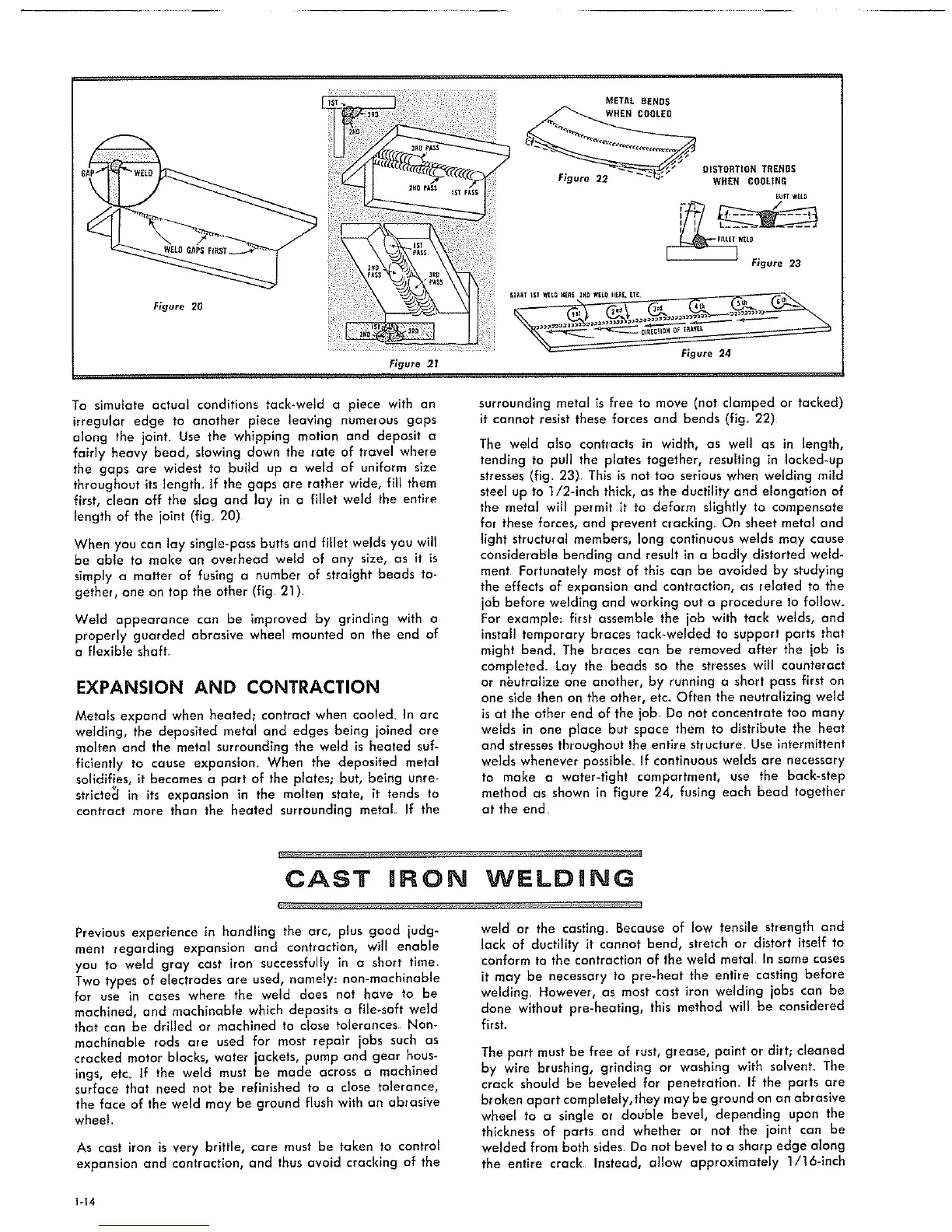

Figure 21

Figure 20

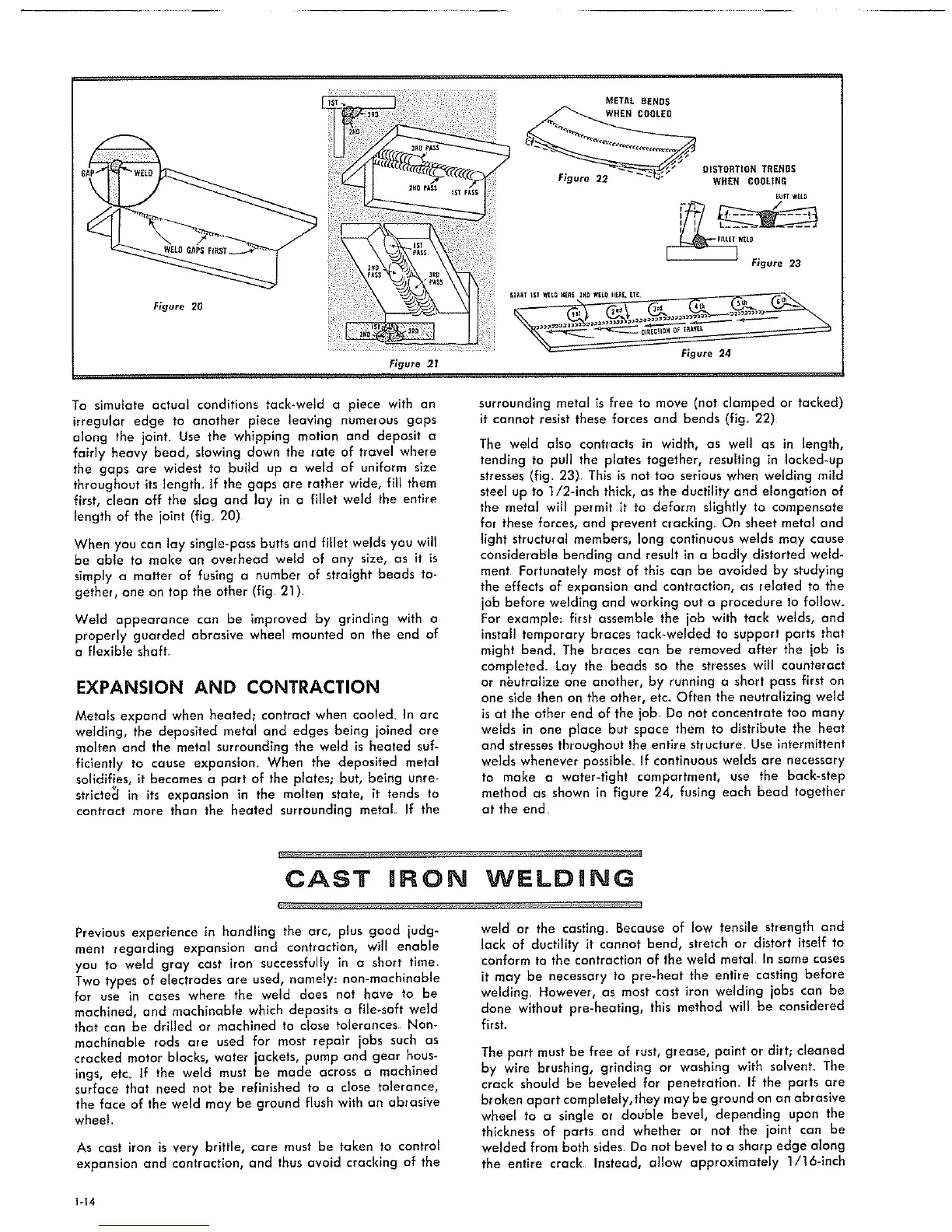

METAL BENDS

WHEN COOLED

Figure 22

DISTORTION TRENOS

WHEN COOLING

Egff W[LO

[RtH Y_LO

F Figure 23

To simulate actua! conditions tack-weld a piece with an

irregular edge to another piece leaving numerous gaps

along the joint_ Use the whipping motion and deposit a

fairly heavy bead, slowing down the rate of travel where

the gaps are widest to build up a weld of uniform size

throughout its length. If the gaps are rather wide, fill them

first, clean off the slag and lay in a fillet weld the entire

length of the joint (fig. 20)

When you can lay single-pass butts and fillet welds you will

be able to make an overhead weld of any size, as it is

simply a matter of fusing a number of straight beads to-

gether, one on top the other (fig 21)

Weld appearance can be improved by grinding with a

properly guarded abrasive wheel mounted on the end of

a flexible shaft

EXPANSION AND CONTRACTION

Metals expand when heated; contract when cooled. In arc

welding, the deposited metal and edges being joined are

molten and the metal surrounding the weld is heated suf-

ficiently to cause expansion_ When the deposited metal

solidifies, it becomes a part of the plates; but, being unre-

stricte_ in its expansion in the molten state, it tends to

contract more than the heated surrounding metal If the

Figure 24

surrounding metal is free to move (not clamped or tacked)

it cannot resist these forces and bends (flg_ 22)

The weld also contracts in width, as well as in length,

tending to pull the plates together, resulting in locked-up

stresses (fig_ 23) This is not too serious when welding mild

steel up to 1/2-inch thick, as the ductility and elongation of

the metal will pelmit it to deform slightly to compensate

for these forces, and prevent cracking. On sheet metal and

light structural members, long continuous welds may cause

considerable bending and resuJt in a badly distorted weld-

ment Fortunately most of this can be avoided by studying

the effects of expansion and contraction, as related to the

job before welding and working out a procedure to follow.

For example: first assemble the job with tack welds, and

install temporary braces tack-welded to support parts that

might bend. The braces can be removed after the job is

cornpleted_ Lay the beads so the stresses will counteract

or nbutralize one another, by running a short pass first on

one side then on the other, etc. Often the neutralizing weld

isat the other end of the job Do not concentrate too many

welds in one place but space them to distribute the heat

and stresses throughout the entire structure Use intermittent

welds whenever possible_ If continuous welds are necessary

to make a water-tight compartment, use the back-step

method as shown in figure 24, fusing each bead together

at the end

CAST IRON WR=LD|NG

Previous experience in handling the arc, plus good judg-

ment regarding expansion and contraction, will enable

you to weld gray cast iron successfully in a short time.

Two types of electrodes are used, namely: non-machinable

for use in cases where the weld does not have to be

machined, and machinable which deposits a file-soft weld

that can be drilled or machined to close tolerances Non-

machinable rods are used for most repair jobs such as

cracked motor blocks, water jackets, pump and gear hous-

ings, etc. If the weld must be made across a machined

surface that need not be refinished to a close tolerance,

the face of the weld may be ground flush with an abrasive

wheel.

As cast iron is very brittle, care must be taken to control

expansion and contraction, and thus avoid cracking of the

weld or the casting_ Because of low tensile strength and

lock of ductility it cannot bend, stretch or distort itseff to

conform to the contraction of the weld metal In some cases

it may be necessary to pre-heat the entire casting before

welding_ However, as most cast iron welding jobs can be

done without pre-heatlng, this method will be considered

first.

The part must be free of rust, grease, paint or dirt; cleaned

by wire brushing, grinding or washing with solvent. The

crack should be beveled for penetration. If the parts are

broken apart completely,they may be ground on an abrasive

wheel to a single or double bevel, depending upon the

thickness of parts and whether or not the ioint can be

welded from both sides. Do not bevel to a sharp edge along

the entire crack Instead, allow approximately 1/16-inch

1-14

Loading...

Loading...