of the fractured surface to line up the two pieces Tack-weld

or clamp parts in position If the crack has not separated

the casting, a vee-groove can be chipped out with a dla-

mond-polnt chisel Chip an inch or so beyond the visible

ends of the crack as it may extend under the surface. On

cracked water jackets, where only a sea! is required, the

depth of the groove need only be one-half the thickness

of the casting.

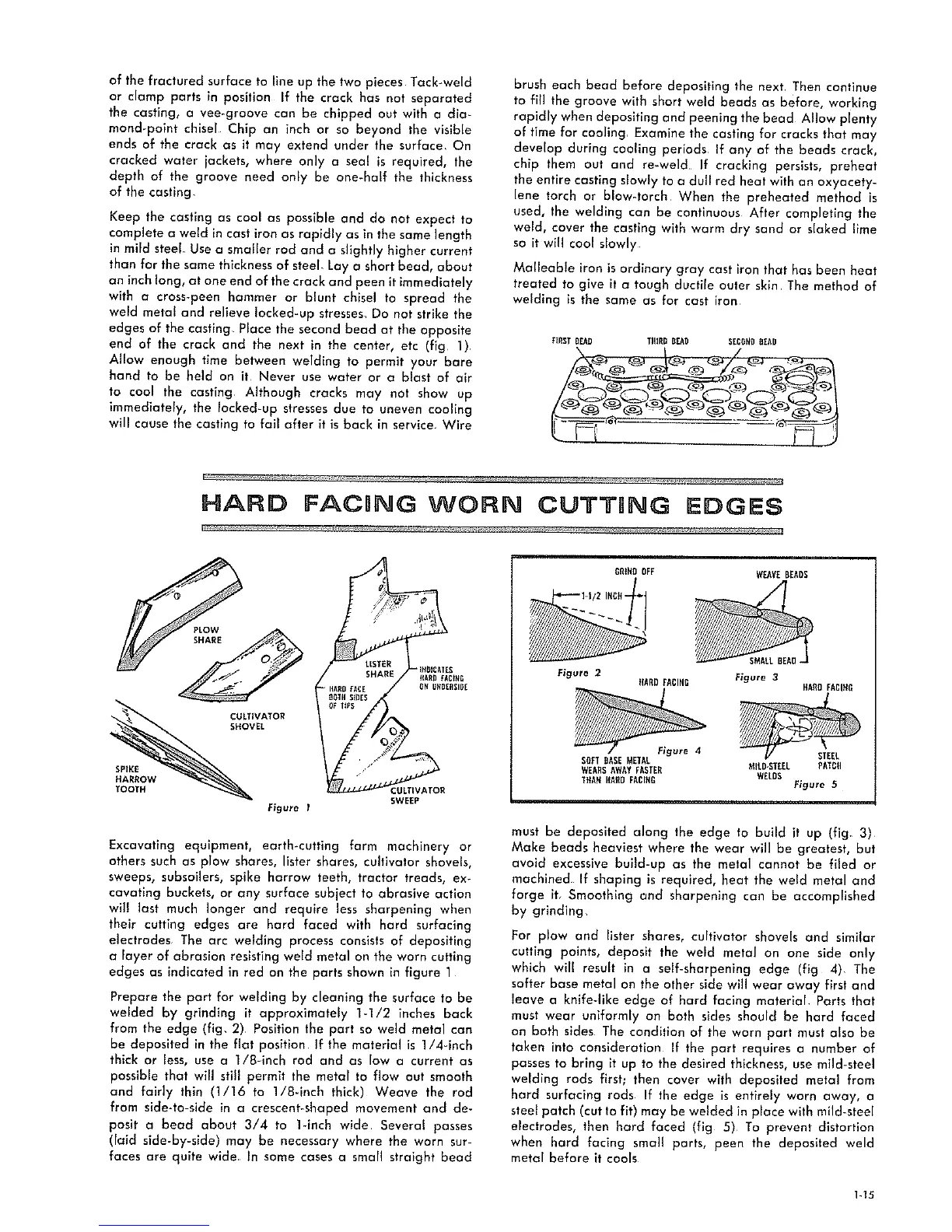

Keep the casting as cool as possible and do not expect to

complete a weld in cast iron as rapidly as in the same length

in mild steel Use a smaller rod and a slightly higher current

than for the same thickness of steel. Lay a short bead, about

an inch long, at one end of the crack and peen it immediately

with a cross-peen hammer or blunt chisel to spread the

weld metal and relieve locked-up stresses, Do not strike the

edges of the casting. Place the second bead at the opposite

end of the crack and the next in the center, etc (fig 1)r

AllOW enough time between welding to permit your bare

hand to be held on it Never use water or a blast of air

to cool the casting Although cracks may not show up

immediately, the locked-up stresses due to uneven cooling

will cause the casting to fail after it is back in service_ Wire

brush each bead before depositing the next Then continue

to fill the groove with short weld beads as before, working

rapidly when depositing and peening the bead Allow plenty

of time for cooling. Examine the casting for cracks that may

develop during cooling periods if any of the beads crack,

chip them out and re-weld If cracking persists, preheat

the entire casting slowly to a dull red heat with an oxyacety-

lene torch or blow-torch When the preheated method is

used, the welding can be continuous After completing the

weld, cover the casting with warm dry sand or slaked lime

so it will cool slowly

Malleable iron is ordinary gray cast iron that has been heat

treated to give it a tough ductile outer skin The method of

welding is the same as for cast iron

HARD FACING WORN CUTTltNG EDGES

PLOW

CULTIVATOR

SHOVEL

SPIKE /

HARROW

TOOTH .'ULTIVATOR

SWEEP

Figure I

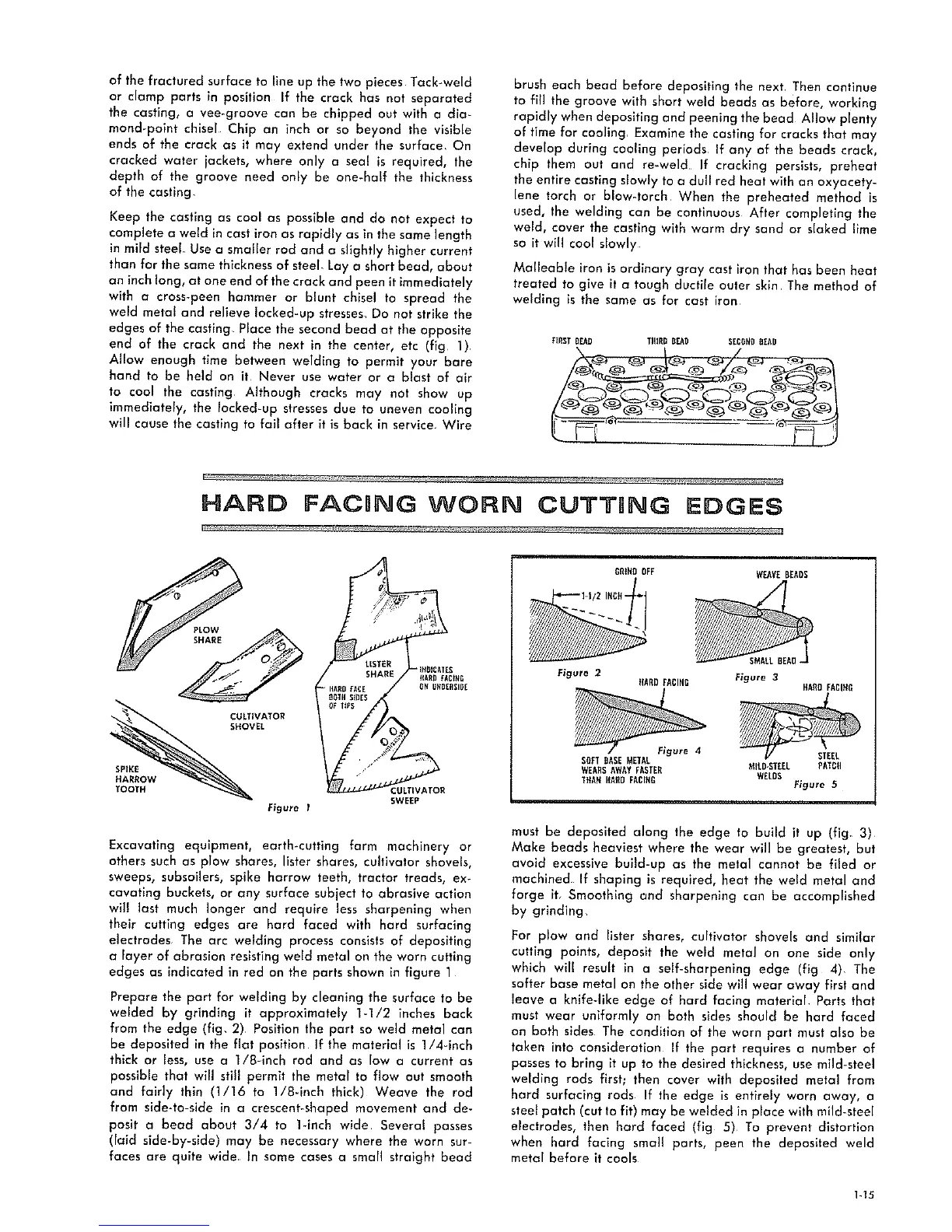

Excavating equipment, earth_cutting farm machinery or

others such as plow shares, lister shares, cultivator shovels,

sweeps, subsoilers, spike harrow teeth, tractor treads, ex-

cavating buckets, or any surface subject to abrasive action

wil! last much longer and require less sharpening when

their cutting edges are hard faced with hard surfacing

electrodes The arc welding process consists of depositing

a layer of abrasion resisting weld metal on the worn cutting

edges as indicated in red on the parts shown in figure 1

Prepare the part for welding by cleaning the surface to be

welded by grinding it approximately 1-1/2 inches back

from the edge (fig. 2) Position the part so weld metal can

be deposited in the flat position If the material is 1/4_inch

thick or less, use a I/8-inch rod and as low a current as

possible that will still permit the metal to flow out smooth

and fairly thin (1/16 to 1/8-1nch thick) Weave the rod

from side-to-side in a crescent-shaped movement and de-

posit a bead about 3/4 to 1-1nch wide Several passes

(lald side-by-slde) may be necessary where the worn sur-

faces are quite wide In some cases a small straight bead

DRtHO OFF WEAVEDEARS

Figure 2

RARD EACIRR

SMALLBEAR-

Figure 3

HA_DEACIHR

SOFTBASEMETAL

WEARSAWAYEASTER MILD,STEEL PATCD

TRAHRAflDFACIDG WELDS

Fieure 5

must be deposited along the edge to build it up (fig. 3)

Make beads heaviest where the wear will be greatest, but

avoid excessive build-up as the metal cannot be filed or

machined If shaping is required, heat the weld metal and

forge it. Smoothing and sharpening can be accomplished

by grinding.

For plow and lister shares, cultivator shovels and similar

cutting points, deposit the weld metal on one side only

which will result in a self-sharpenlng edge (fig 4) The

softer base metal on the other side will wear away first and

leave a knlfe-like edge of hard facing material Parts that

must wear uniformly on both sides should be hard faced

on both sides The condition of the worn part must also be

taken into consideration If the part requires a number of

passes to bring it up to the desired thickness, use mild-steel

welding rods first; then cover with deposited metal from

hard surfacing rods If the edge is entirely worn away, a

steel patch (cutto fit) may be welded in place with mild-steel

electrodes, then hard faced (fig 5) To prevent distortion

when hard facing small parts, peen the deposited weld

metal before it cools

1-15

Loading...

Loading...