Loading...

Loading...

Do you have a question about the Craftsman 113.201372 and is the answer not in the manual?

| Model Number | 113.201372 |

|---|---|

| Category | Welding System |

| Input Voltage | 120V |

| Output Current | 70A |

| Duty Cycle | 20% at 70A |

| Welder Type | MIG |

| Welding Process | MIG (GMAW) |

| Wire Size | 0.030 in. |

Guidelines for preventing electric shock hazards during welding operations.

Requirements for protective gear to shield eyes and body from arc rays, sparks, and debris.

Precautions for handling flammable materials and preventing fires around the welding area.

Essential checks and upkeep procedures for the welding equipment to ensure safety and performance.

An overview of the operational procedures and setup for the arc welder.

Instructions for safely unpacking the welder and verifying all included parts.

List of tools required to perform the welding machine assembly steps.

Guide on correctly connecting the work clamp to the welding cable.

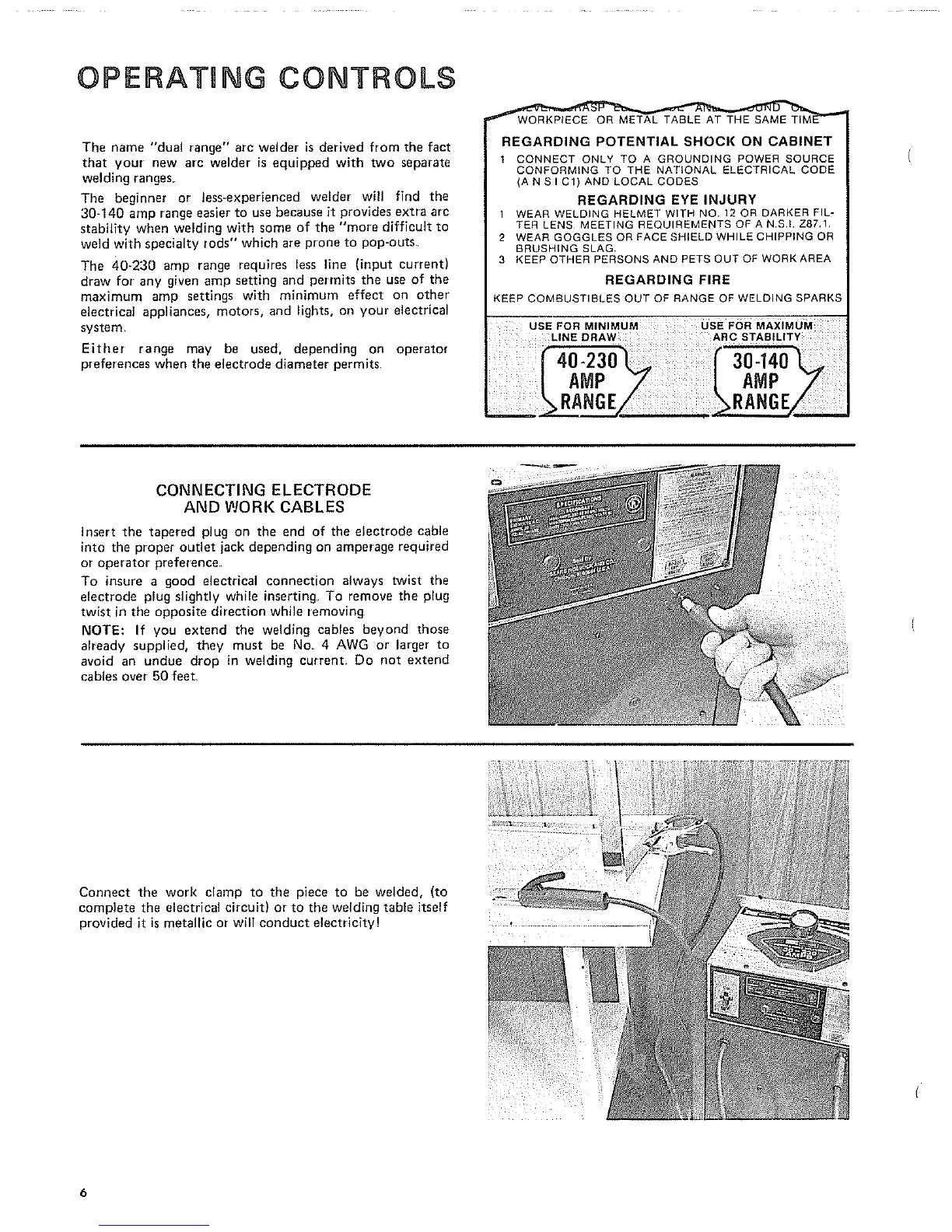

Steps for connecting the electrode holder and work clamp cables to the welder.

How to select the correct electrode diameter and set the amperage for welding.

Guidance on proper welding techniques and essential safety measures during operation.

A structured chart detailing common issues and solutions for the welding equipment.

Overview of the welder's capabilities and how it functions.

Explanation of how the specific electrode design enhances welding ease and quality.

A detailed explanation of the arc welding process and the science behind it.

Detailed methods for performing welds in the vertical plane, including down and up techniques.

Procedures for executing welds on joints oriented horizontally.

Techniques for performing welds in the overhead position, requiring specific precautions.

Using the arc welder to efficiently remove bolts and rivets.

Techniques for creating holes in metal using the arc welding process.

Utilizing the carbon arc for localized metal heating applications.

Information on suitable shielding gases (Argon, Helium) for TIG welding.

Guide to selecting appropriate current settings for various metals in TIG welding.

A comprehensive list of part numbers and descriptions for ordering replacements.