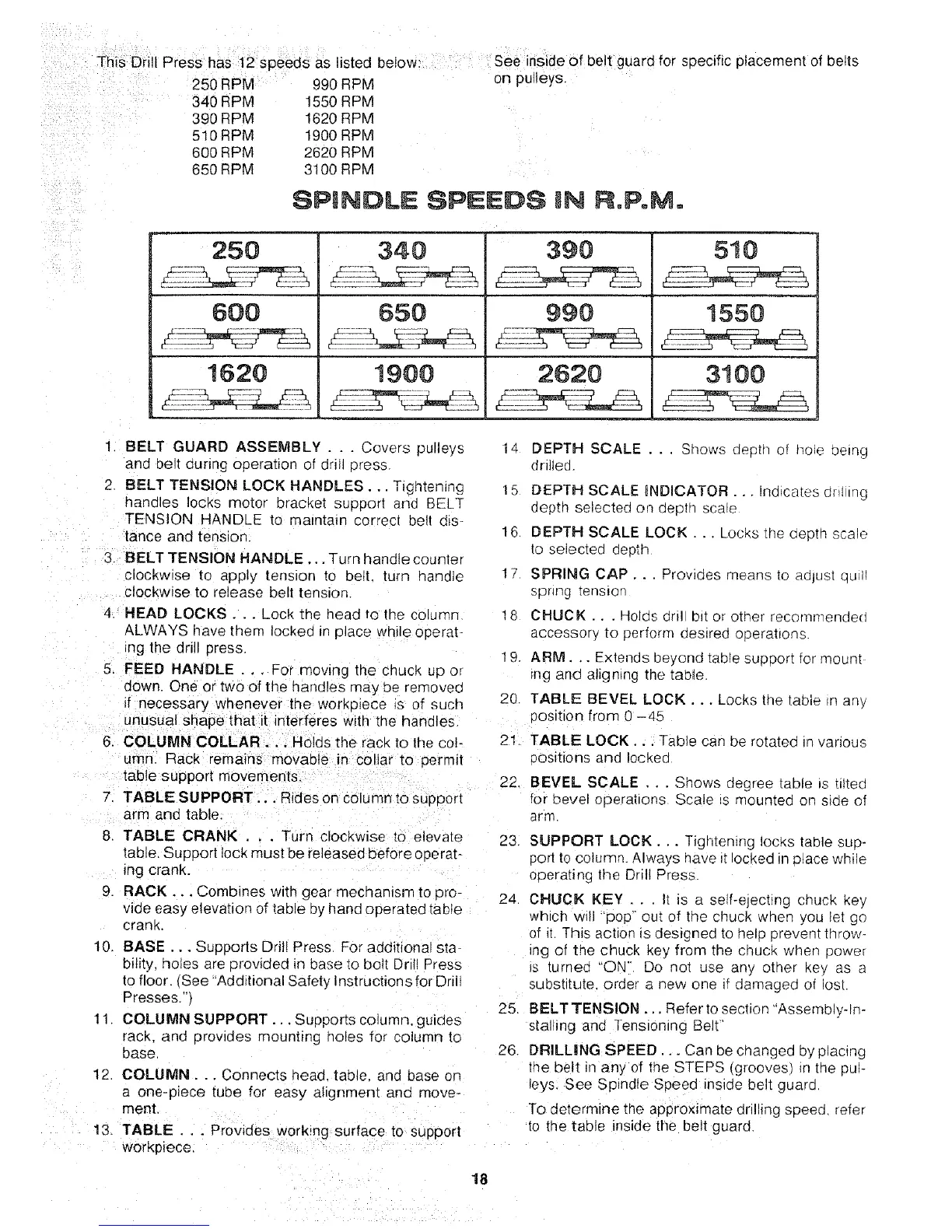

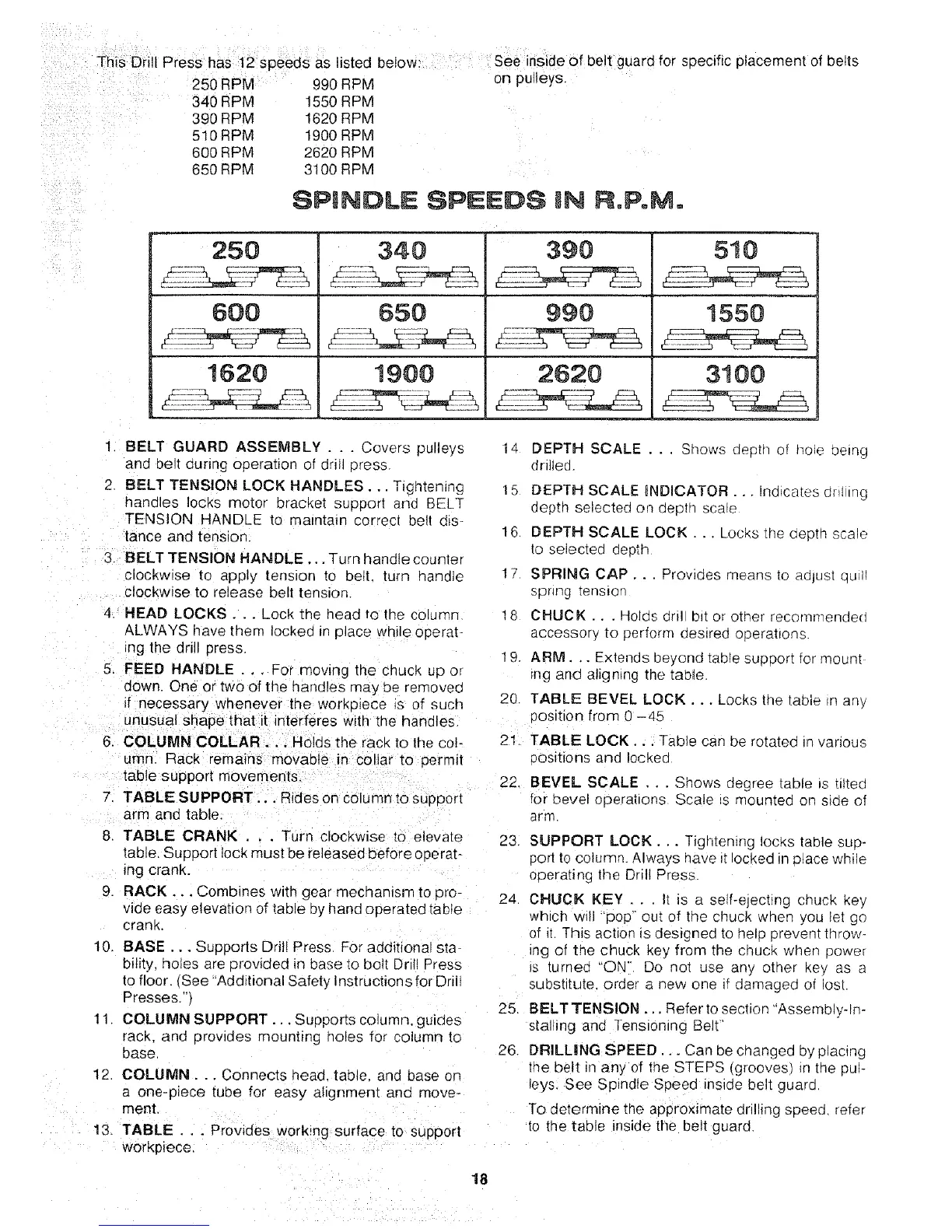

T_I_ Diili Press has t2 sp_ed_ as listed belowi : see inside of be!t guard for specific placement of belts

.... o_n_...,u,,,,,,D°_ 990 RPM on pulleys.

/ ii ¸

i_i,_ii_i_ii '_i_ i_i

340 RPM 1550 RPM

390 RPM 1620 RPM

510 RPM 1900 RPM

600 RPM 2620 RPM

650 RPM 3100 RPM

SPINDLE SPEEDS IN RoPoMo

250

600

1620

340

650

1900

390

990

2620

510

1550

3!00

1. BELT GUARD ASSEMBLY . . . Covers pulleys

and belt during operauon of drill press.

2 BELT TENSION LOCK HANDLES... Tightening

handles locks motor bracket support and BELT

TENSION HANDLE to maintain correct be!t dtS-

tance and tenston.

3, BELT TENSION HANDLE ... Turn handle counter

clockwise to apply tension to belt. turn handle

clockwise to release belt tension.

4. HEAD LOCKS... Lock tne head to the column

ALWAYS qave thenq locked in place while operab

_ng the drill press

5. FEED HANDLE . . . For moving the chuck up or

down, One or two of the handles may oe removeo

if necessary whenever the worKo_ece _s of such

unusual shape that it interferes w_th the handles

6. COLUMN COLLAR ... Holds the rack to the col-

umn. Rack remafns movable in collar to permit

table support movements.

7. TABLE SUPPORT,.. Rides on column to support

arm and table.

8. TABLE CRANK . . . Turn clockwise to elevate

table. Support lock must be released before operat-

ing crank.

9 RACK... Combines with gear mechanism to pro-

vide easy elevation of table byhand operated table

crank

10.

BASE... Supports Drill Press For additional sta-

bility, holes are provided in base to bolt Dril Press

to floor. {See 'Additional Safety Instructions for Drill

Presses.q

11 COLUMN SUPPORT... Supports column, guides

rack. and provides mounting holes for column to

ease

12. COLUMN... Connects iqead, table, ana ease on

a one-piece tube for easy alignment and move-

ment.

13. TABLE . . . Provides working surface to support

workpiece.

DEPTH SCALE . .. Shows depth of hope being

drllleo.

14

15 DEPTH SCALE _NDICATOR... Indrcates dr_t ing

depth selected on depth sca=e

16 DEPTH SCALE LOCK... Locks :no oepth scale

to selected aeoth

1• SPRING CAP... Provides means to adjust qu_ll

spnng _ension

18 CHUCK... Holc_s dril b_t or otlqer recornnended

accessory to perform posited operations

9. ARM... Extends oeyond tabte suDoort for mount

_ng ancJ ahgntng the table.

20. TABLE BEVEL LOCK... Locks the table Jn any

Position from 0 -45

21. TABLE LOCK... Table can be rotated in various

3ositions and poked

22. BEVEL SCALE ... Shows degree table is tiited

for bevel operahons Scale _s mounted on side of

arm.

23.

24

25

26

SUPPORT LOCK. . Tigntentng locks table sup-

port to column. Always have =tlocked in place while

operating the Dri Press.

CHUCK KEY . . . It is a self-ejechng chuck key

which wil "pop" out of tlqe chuck wnen you let go

of i[ This action is designed to help prevent throw-

ing of the chuck key from the cnuc_ when power

Js _urnec "ON" Do qot use any other key as a

substitute order a new one if damagea of iost

BELT TENSION,.. Refer to section "Assem 31y-In-

stalling and ]ension_ng Belt"

DRILLING SPEED... Can be changed by placing

the uelt in any of the STEPS tgroovesl n the puF

leys. See Spindle Speed inside belt guarG

To determine the ao#roximate drilling speed refer

to the table inside the belt guard.

18

Loading...

Loading...