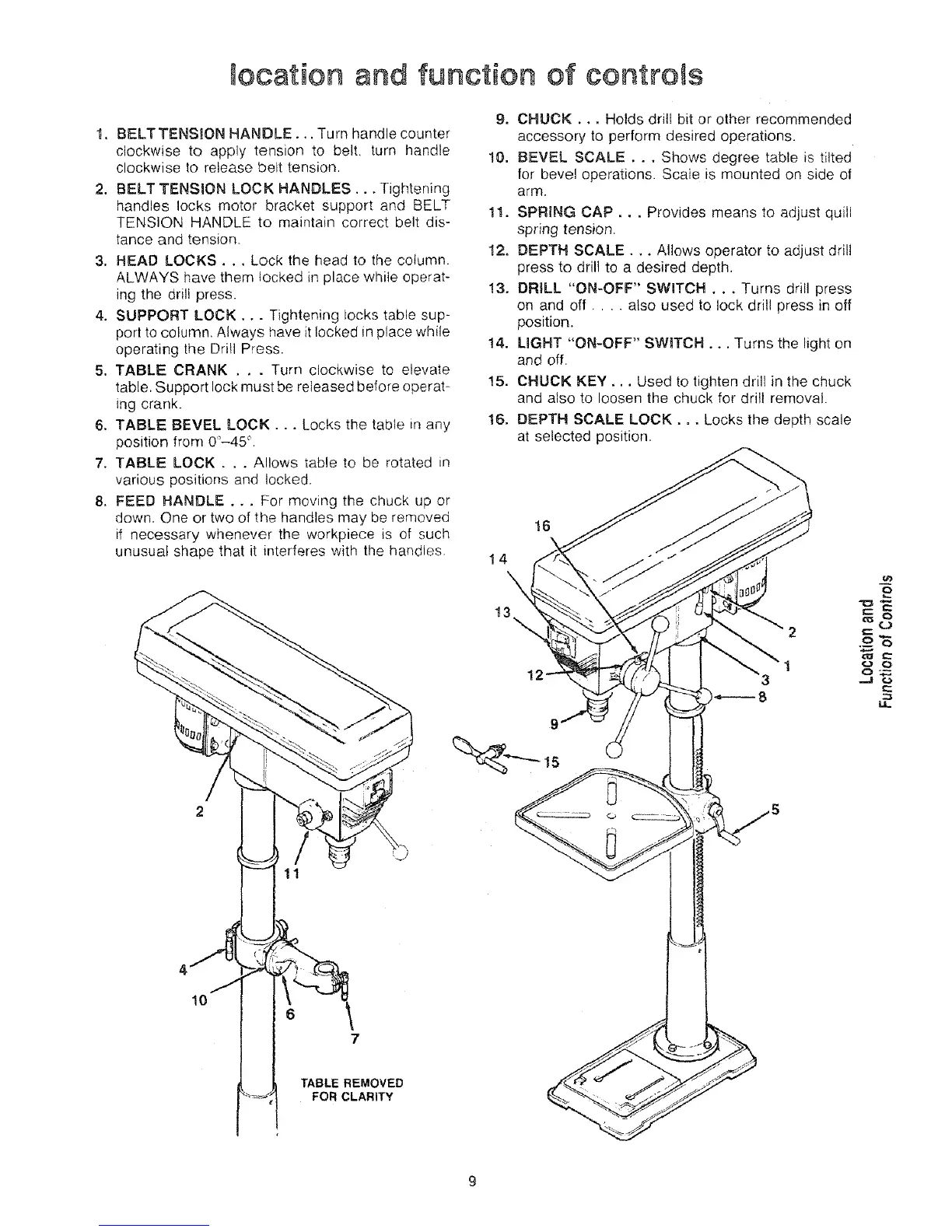

ooation and function of controls

1. BELTTENSION HANDLE... Turn handle counter

clockwise to apply tension to belt, turn handle

clockwise to release belt tension.

2. BELT TENSION LOCK HANDLES... Tightening

handles locks motor bracket support and BELT

TENSION HANDLE to maintain correct belt dis-

tance and tension.

3. HEAD LOCKS, ., Lock the head to the column.

ALWAYS have them locked in place while operat-

ing the drill press.

4. SUPPORT LOCK... Tightening locks table sup-

port to column. Always have it locked in place while

operating the Drill Press.

5. TABLE CRANK . . . Turn clockwise to elevate

table. Support lock must be released before operat-

ing crank.

6. TABLE BEVEL LOCK... Locks the table in any

position from 0"-45 °

7. TABLE LOCK... Allows table to be rotated in

various positions and locked.

8. FEED HANDLE . . . For moving the chuck up or

down. One or two of the handles may be removed

if necessary whenever the workpiece is of such

unusual shape that it interferes with the handles.

9. CHUCK... Holds drill bit or other recommended

accessory to perform desired operations,

10, BEVEL SCALE . .. Shows degree table is tilted

for bevel operations. Scale is mounted on side of

arm.

11. SPRUNG CAP,.. Provides means to adjust quill

spring tension.

12. DEPTH SCALE... Allows operator to adjust drill

press to drill to a desired depth.

13. DRILL "ON-OFF" SWITCH ... Turns drill press

on and off .... also used to lock drill press in off

position.

14. LIGHT "ON-OFF" SWITCH... Turns the light on

and off.

t5. CHUCK KEY... Used to tighten drill in the chuck

and also to loosen the chuck for drill removal.

16, DEPTH SCALE LOCK.., Locks the depth scale

at selected position.

14

16

13

10

6

7

TABLE REMOVED

FOR CLARITY

P

Q

Q

0:._.

£::::