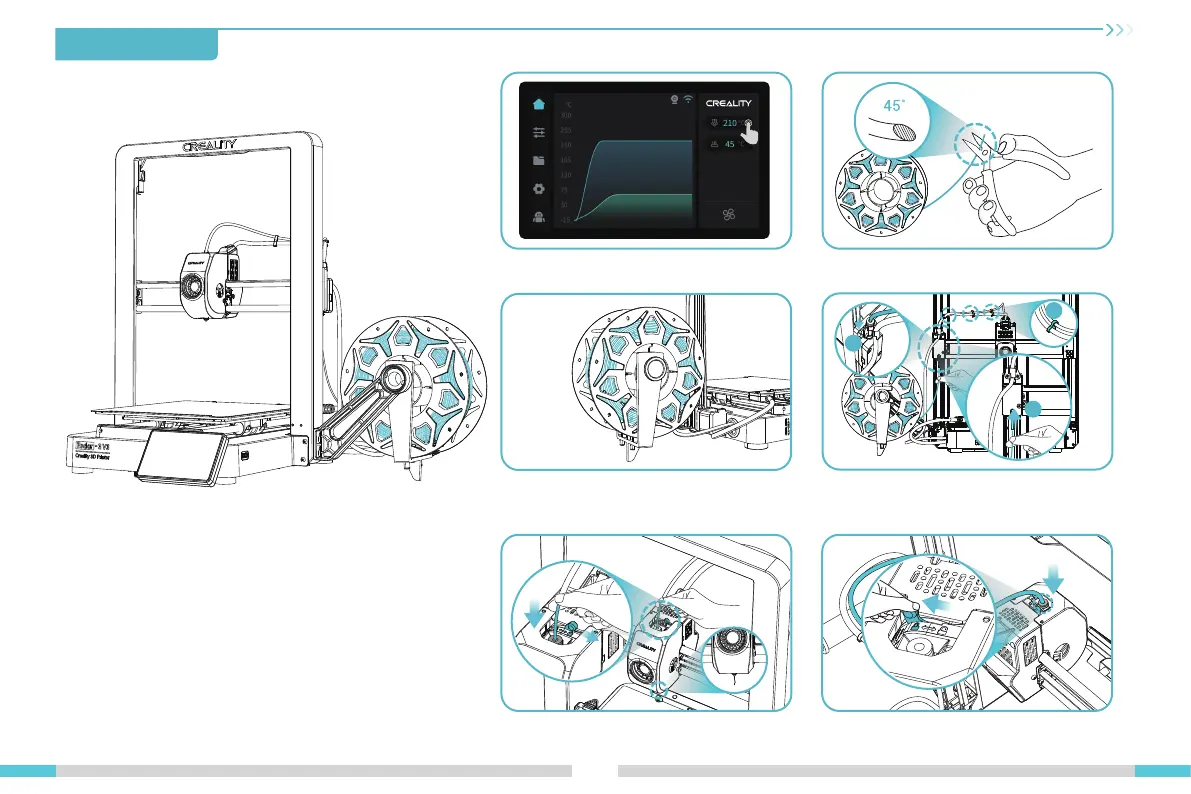

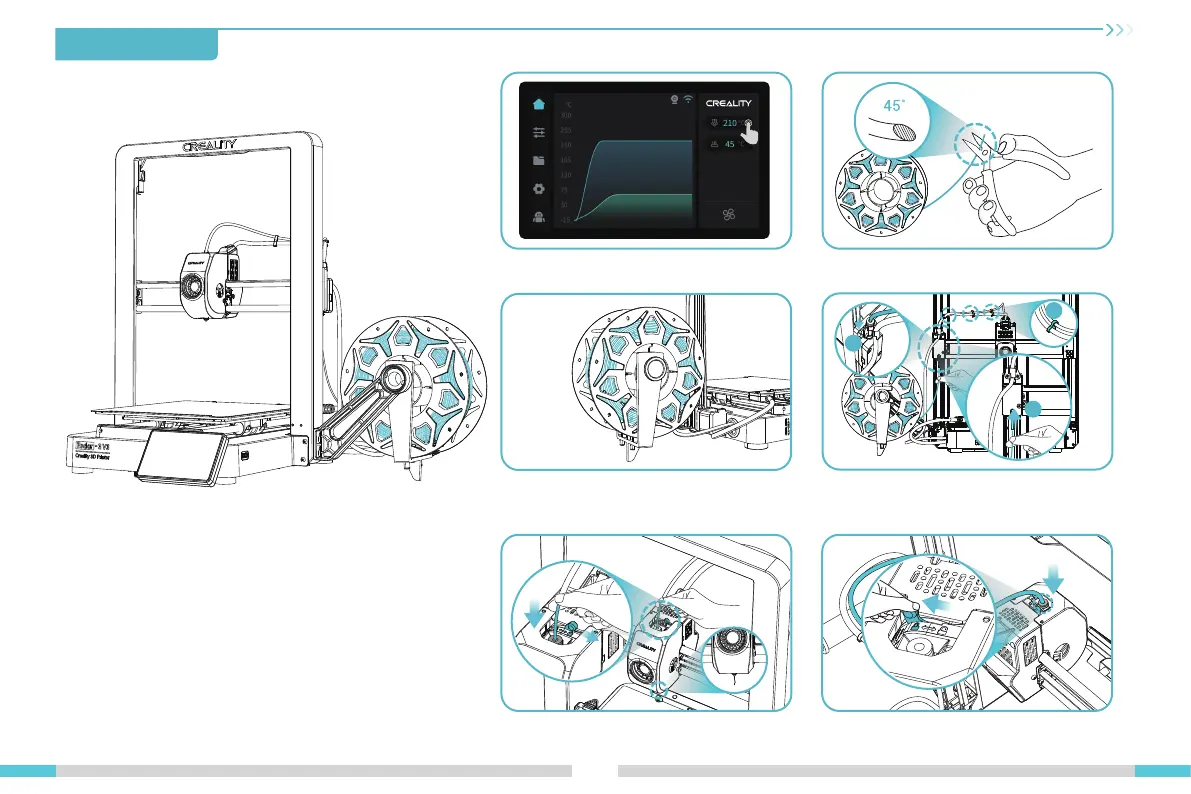

5.First Printing

5.1 Filament Loading

12

② Cut the front of the filament at 45° and break it

off straight;

④ A. Connect the Teflon tube to filament runout sensor;

B.And thread the filament into filament detection port

until it passes through the Teflon tube; C. Fix the Teflon

tube with extruder cable with cable clips.

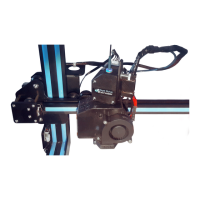

⑥ Lock the DIP switch, and insert the Teflon tube into the

upper joint of the extruder kit.

⑤ Unlock the DIP switch and thread the filament into the

extruder kit until the filament is extruded from the nozzle;

① Input the nozzle temperature on the screen and wait

for it to heat up to the target temperature;

③ Arrange the filaments as shown in the picture, and

then install the anti-tangle material rack;

A

B

C

Loading...

Loading...