3.9 Troubleshooting

3.10 Power Conditions and

Shielding Conceptions

Symptom: Possible cause(s):

LED off • Check power supply. Check wiring.

• DGS MODBUS was possibly damaged in transit. Check by installing another DGS

to confirm the fault.

Green flashing • The sensor calibration interval has been exceeded or the sensor has reached the

end of life. Carry out calibration routine or replace with a new factory calibrated

sensor.

Yellow • AO configured but not connected (only 0 – 20 mA output). Check wiring.

• Sensor type does not match DGS specification. Check gas type and measuring

range.

• Sensor may be disconnected from printed circuit board. Check to see if the sensor

is properly connected.

• The sensor has been damaged and needs to be exchanged. Order replacement

sensor from Danfoss.

• Supply voltage out of range. Check power supply.

Yellow flashing • The DGS is set to service mode from the hand-held Service Tool. Change setting

or await time-out within 15 minutes.

Alarms in the absence

of a leak

• If you experience alarms in the absence of a leak, try setting an alarm delay.

• Perform a bump test to ensure proper operation.

The zero-measurement

drifts

The DGS-SC sensor technology is sensitive to the environment (temperature, moist,

cleaning agents, gases from trucks, etc). All ppm measurements below 75 ppm

should be disregarded, i.e. no zero-adjustment made.

Standalone DGS without Modbus network communication

Shield/screen is not required for standalone DGS with no connection to a RS-485 communication line.

However, it can be done as described in the next paragraph (Fig. 4).

DGS with Modbus network communication in combination with other devices powered by the

same power supply

It is strongly recommended to use direct current power supply when:

• more than 5 DGS units are powered by the same power supply

• the bus cable length is longer than 50 m for those powered units

It is moreover recommended to use class 2 power supply (see AK-PS 075)

Make sure to not interrupt the shield when connecting A and B to the DGS (see Fig. 4).

Fig. 4: Loop trough

A

+

B

–

Danf

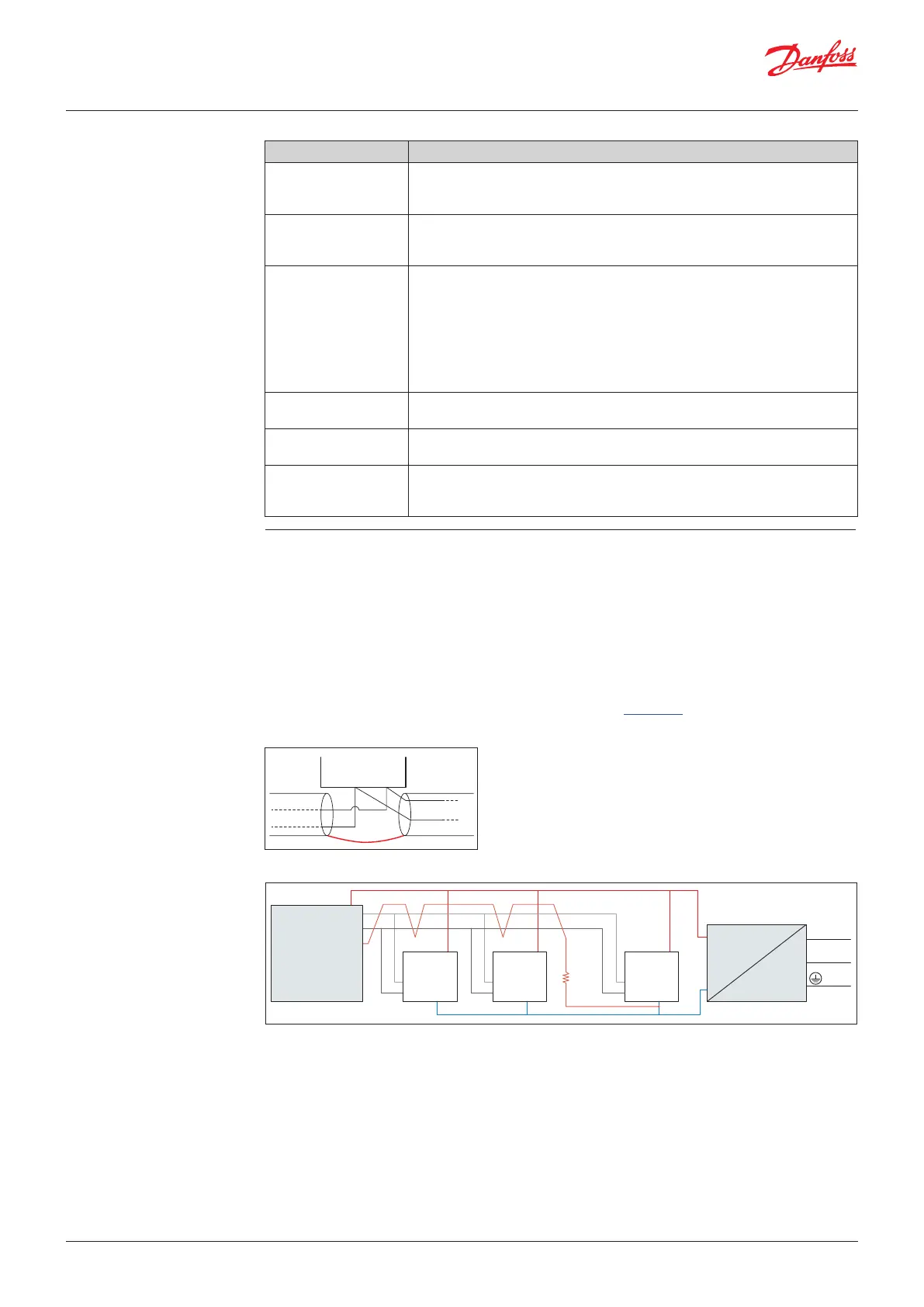

Ground potential difference between nodes of the RS485 network might affect the communication.

It is advised to connect a 1 KΩ 5% ¼ W resistor between the shield and the ground (X4.2) of any unit

or group of units connected to the same power supply (Fig. 5).

Please refer to Literature No. AP363940176099.

Fig. 5: Wiring diagram for system with one power supply

Danfoss

80Z876

L

N

230 V

DGS 1

#adr 10

Shield

+

A

B Gnd

DGS 2

#adr 11

+

A

B Gnd

DGS n

#adr xx

1 KΩ

+

A

B Gnd

AK-PS 075 power supply

A

B

Shld

Danfoss

Modbus

device

+

–

Input 230 V

User Guide | Danfoss Gas sensor, type DGS

© Danfoss | Climate Solutions | 2022.01 BC291049702513en-000201 | 7

Loading...

Loading...