Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Electrical troubleshooting

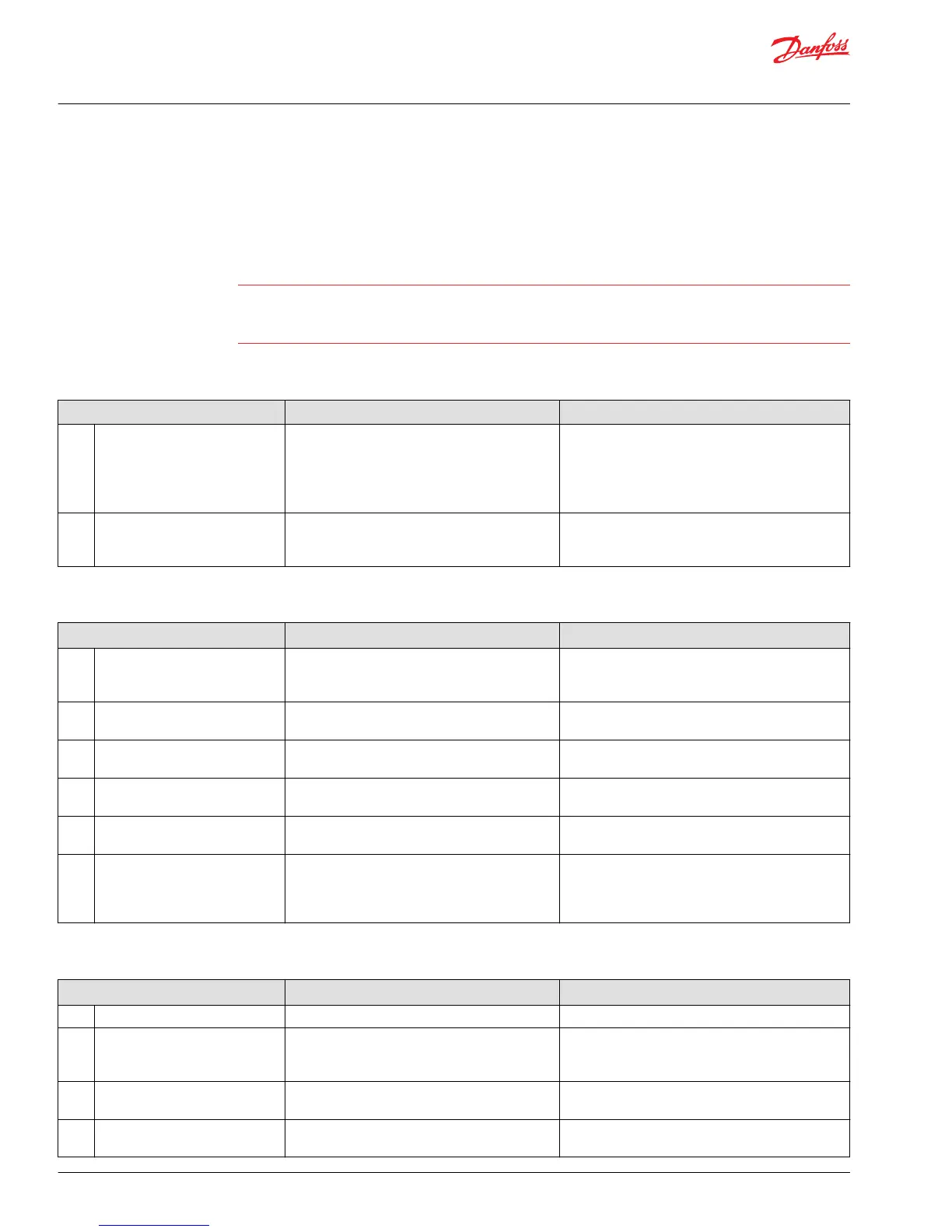

Check Cause Corrective action

1.

Motor operates at one

displacement only.

Control coil failure

Measure resistance at coil pins. Resistance at 20°C

[70°F] should be:

•

Proportional controls: 14.20 Ω (24V) or 3.66 Ω (12V)

•

Two-position controls: 8.4 Ω (24V) or 34.5 Ω (12V)

Replace coil if necessary.

2. Erratic motor function Electrical connection to motor is intermittent.

Disconnect connector, check wires and terminals,

reconnect wires. Check terminals for corrosion and

correct position.

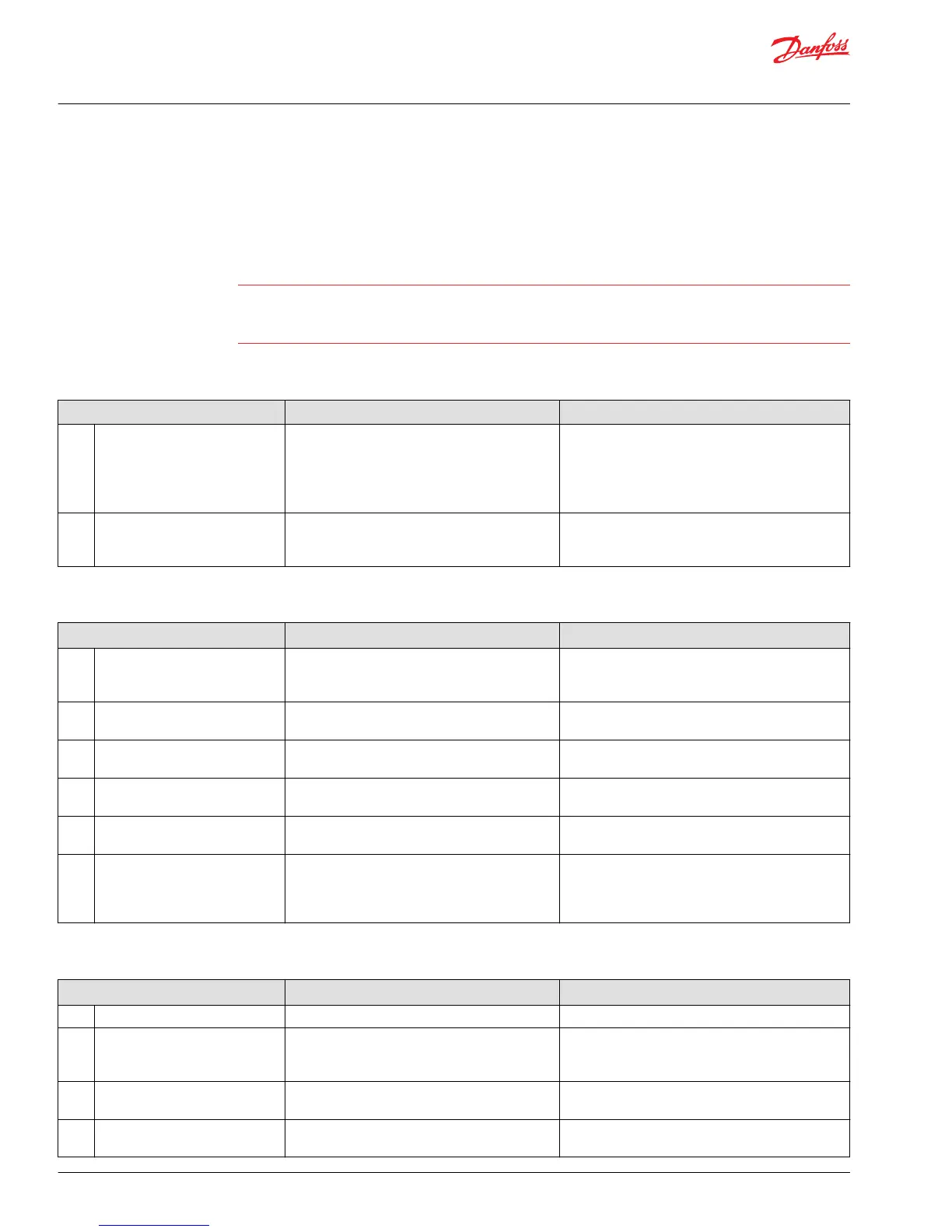

Sluggish operation

Check Cause Corrective action

1. Control orifices Blocked or restricted orifice may cause sluggish

response. Orifices installed in the wrong locations

may cause PCOR control to be sluggish.

Remove, inspect and clean all orifices. Ensure the

appropriate orifices are installed and in the correct

location.

2. Threshold setting (proportional

controls)

Inappropriately high or low threshold setting may

shift the motor at the wrong time.

Check threshold setting. Adjust if necessary.

3. Control spool A sticky control may cause sluggish response or no

response.

Clean and inspect the control spool. Replace if

necessary.

4. Pressure compensator setting Low pressure compensator setting may shift motor

to maximum displacement at lower pressure.

Check pressure compensator setting. Adjust if

necessary.

5. Control input signal An improper or erratic input signal to the control

may cause sluggish response.

Check input signal and correct if necessary.

6. Internal leakage Excessive leakage will cause lower charge pressure

and affect performance.

Install loop flushing defeat option and measure case

flow. If case flow is excessive, motor may require major

repair. Contact your Danfoss authorized service

center.

System operating hot

Check Cause Corrective action

1. Oil level Insufficient hydraulic fluid may cause overheating. Fill reservoir to proper level.

2. Heat exchanger Blocked heat exchanger or low air flow may cause

system overheating.

Check temperature upstream and downstream of heat

exchanger. Clean, repair, or replace heat exchanger if

necessary.

3. Loop flushing flow Restricted orifice in loop flushing cartridge reduces

flow.

Measure case drain flow. Clean or replace orifice

cartridge.

4. Loop flushing shuttle Loop flushing shuttle may be sticking in one

direction.

Ensure shuttle moves freely in its bore.

Service Manual

H1 Bent Axis Motors, Size 060/080/110/160/210/250 cm3

Troubleshooting

30 |

©

Danfoss | August 2018 AX00000025en-US0504

Loading...

Loading...