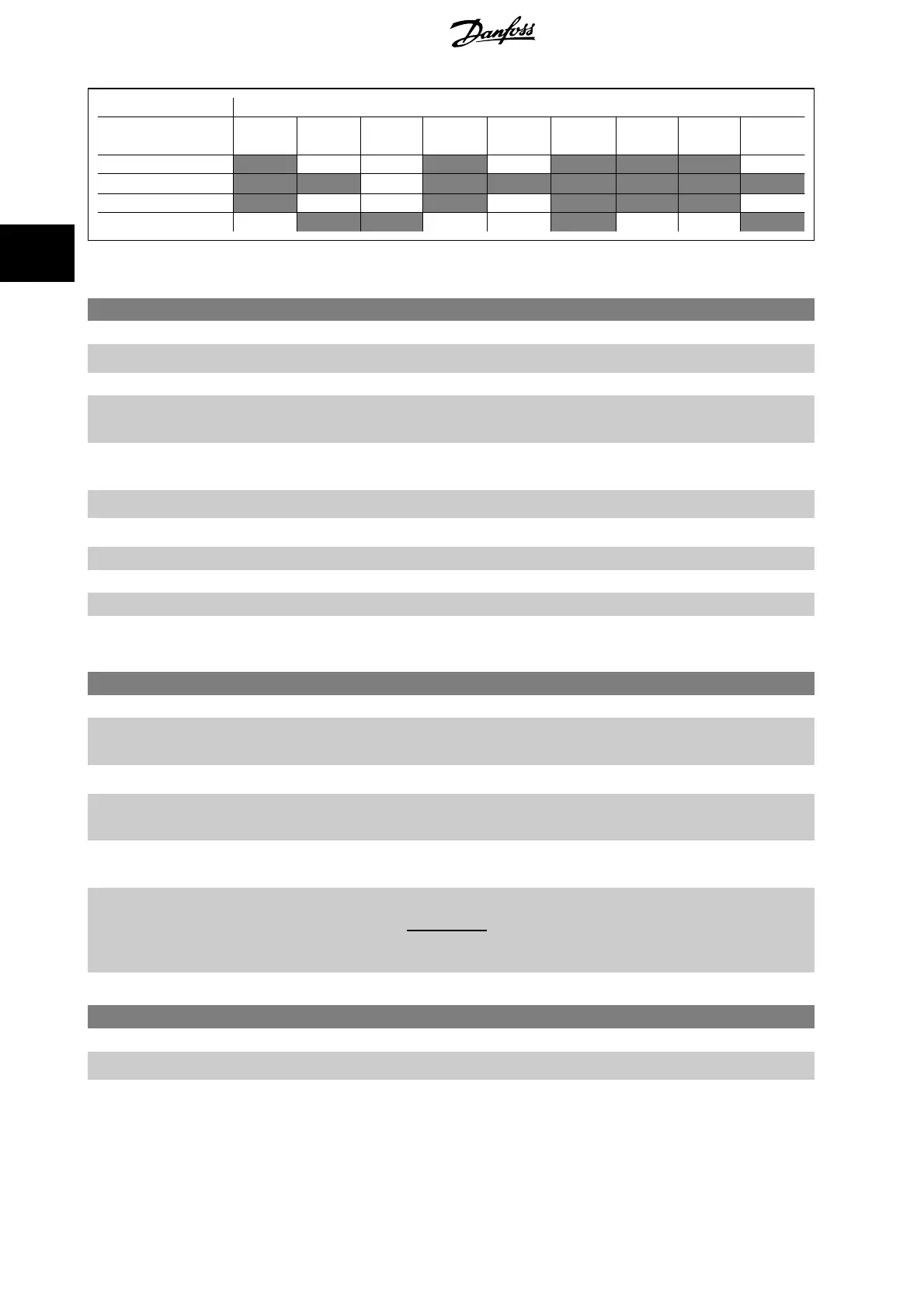

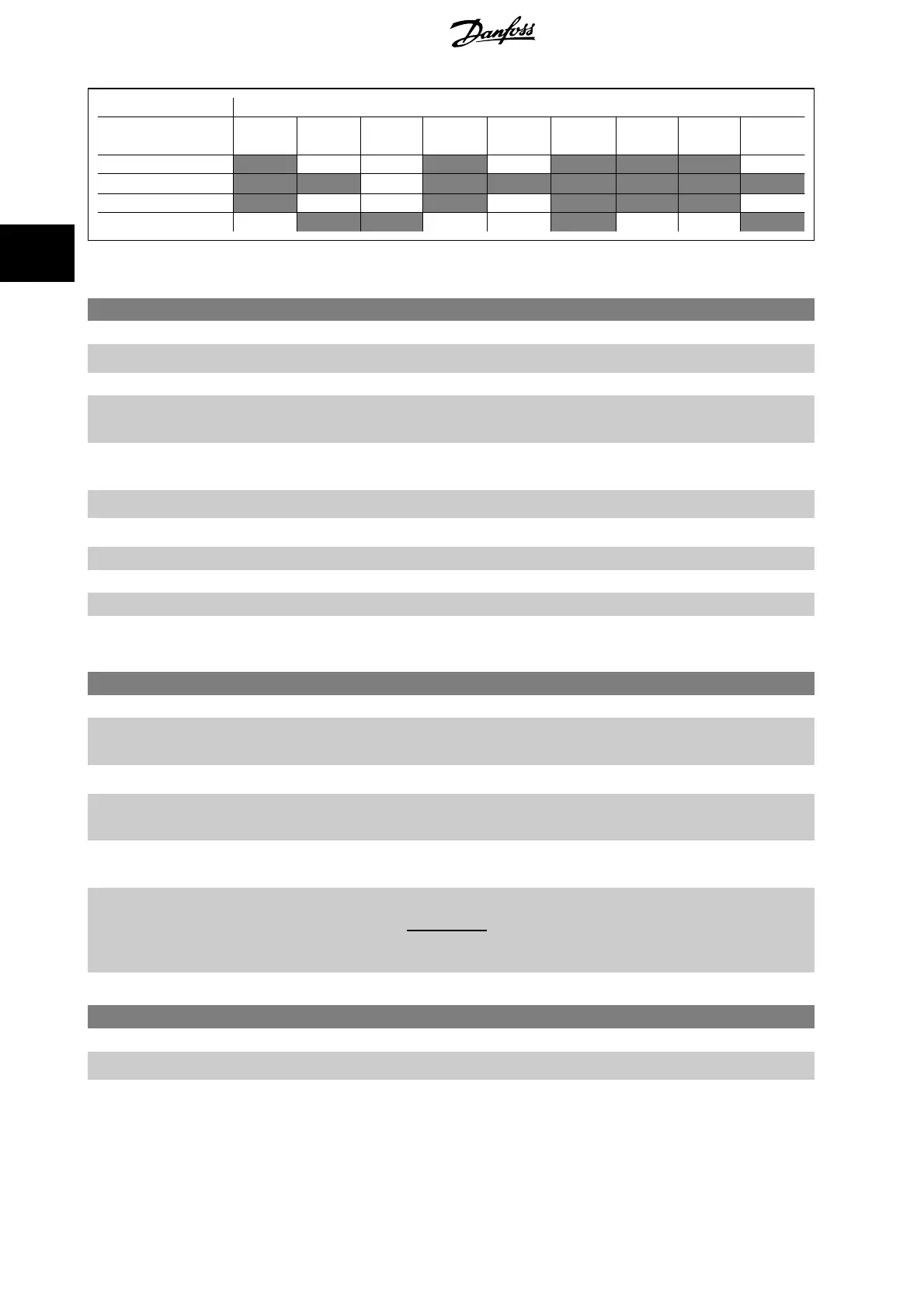

Par. 1-00

Par. 1-01 [0] Speed

OL

[1] Speed

CL

[2] Torque [3] Process [4] Torque

OL

[5] Wobble [6] Surface

Wnd

[7] Ext. PID

OL

[8] Ext. PID

CL

[0] U/f

[1] VVC

plus

[2] Flux sensorless

[3] Flux w/ motor feedback

Table 3.3: Overview of possible combinations of the settings in par. 1-00

Configuration Mode

and par. 1-01

Motor Control Principle

. The gray cells mark

the possible combinations.

1-02 Flux Motor Feedback Source

Option: Function:

Select the interface at which to receive feedback from the motor.

[0] Motor feedb. P1-02

[1] * 24V encoder A and B channel encoder, which can be connected to the digital input terminals 32/33 only. Termi-

nals 32/33 must be programmed to

No operation

.

[2] MCB 102 Encoder module option which can be configured in par. group 17-1*

This parameter appears in FC 302 only.

[3] MCB 103 Optional resolver interface module which can be configured in par. group 17-5**

[5] MCO Encoder 2 encoder interface 2 of the optional programmable motion controller MCO 305.

[6] Analog input 53

[7] Analog input 54

[8] Frequency input 29

[9] Frequency input 33

This parameter cannot be adjusted while the motor is running.

1-03 Torque Characteristics

Option: Function:

Select the torque characteristic required.

VT and AEO are both energy saving operations.

[0] * Constant torque Motor shaft output provides constant torque under variable speed control.

[1] Variable torque Motor shaft output provides variable torque under variable speed control. Set the variable torque

level in par. 14-40

VT Level

.

[2] Auto Energy Optim. Automatically optimises energy consumption by minimising magnetisation and frequency via

par. 14-41

AEO Minimum Magnetisation

and par. 14-42

Minimum AEO Frequency

.

[5] Constant Power The function provide a constant power in field weakening area. Follows the formula:

P

constant

=

Torque

x

RPM

9550

This selection maybe unavailable depending on drive configuration.

This parameter cannot be adjusted while the motor is running.

1-04 Overload Mode

Option: Function:

[0] * High torque Allows up to 160% over torque.

[1] Normal torque For oversized motor - allows up to 110% over torque.

This parameter cannot be adjusted while the motor is running.

3 Parameter descriptions FC 300 Programming Guide

46

MG.33.M8.02 - VLT

®

is a registered Danfoss trademark

3

Loading...

Loading...