PE

FC

PE

FC

130BB924.12

PE PE

69

69

68

68

1

2

<10 mm

1

Minimum 16 mm

2

(6 AWG)

2 Equalizing cable

Illustration 4.11 Twisted-pair Cables without Terminal 61

4.7 Jumper Terminals 12 and 27

When the factory default programming values are used,

connect a jumper wire between terminal 12 and terminal

27 for the frequency converter to operate.

•

Digital input terminal 27 is designed to receive a

24 V DC coast command. In many applications,

wire a coast device to terminal 27.

•

When no interlock device is used, wire a jumper

between control terminal 12 and terminal 27. This

provides internal 24 V signal on terminal 27.

•

No signal present prevents the unit from

operating.

•

Only for GLCP: When the status line at the

bottom of the LCP reads AUTO REMOTE COAST, it

indicates that the unit is ready to operate but is

missing an input signal on terminal 27.

4.8

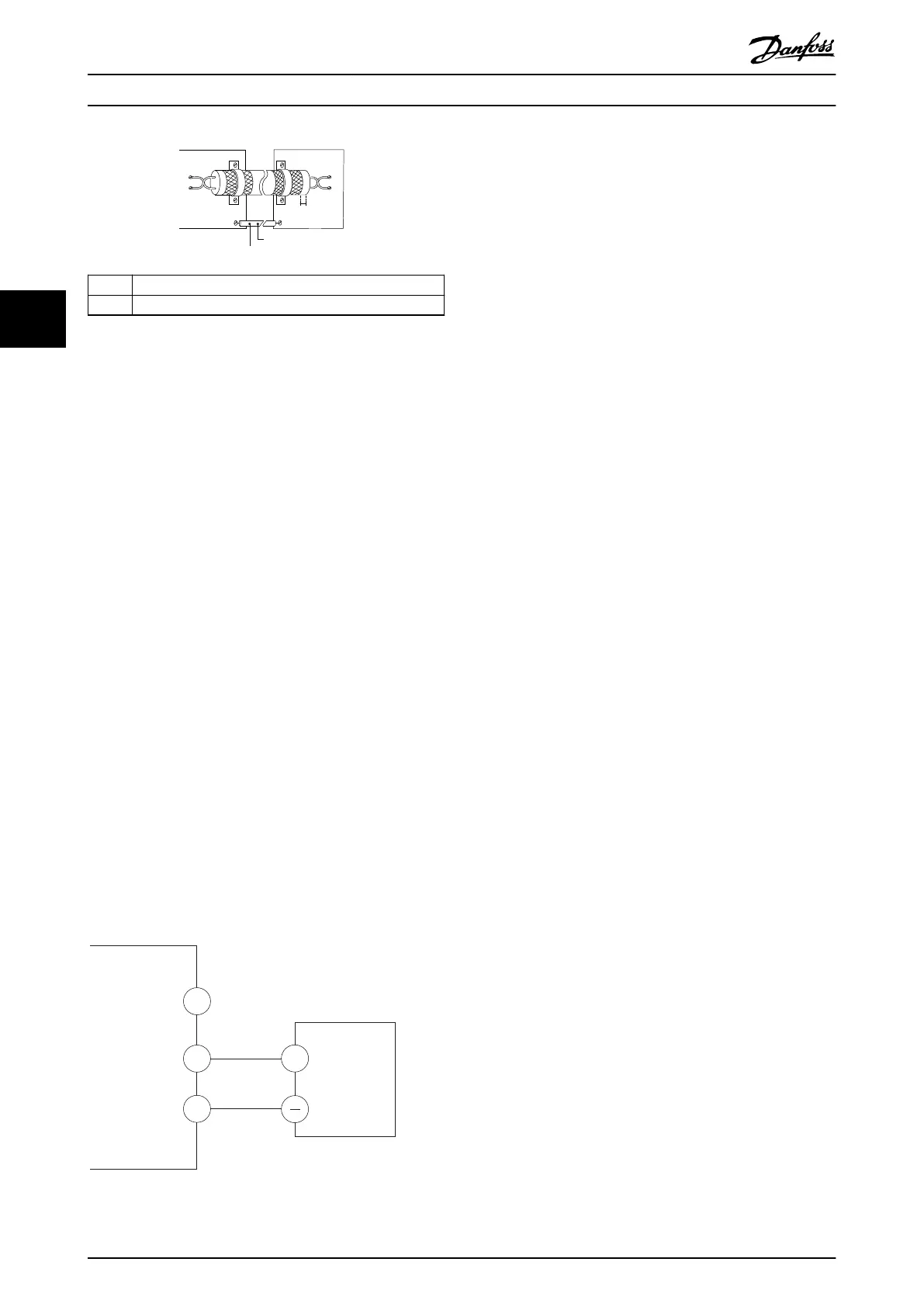

Serial Communication

Connect RS485 serial communication wiring to terminals

(+) 68 and (-) 69.

•

Shielded serial communication cable is

recommended.

•

See chapter 4.3.1 Grounding Requirements for

proper grounding.

Illustration 4.12 Serial Communication Wiring Diagram

For basic serial communication set-up, select the following:

1. Protocol type in parameter 8-30 Protocol.

2. Frequency converter address in

parameter 8-31 Address.

3. Baud rate in parameter 8-32 Baud Rate.

Two communication protocols are internal to the

frequency converter.

•

Danfoss FC

•

Modbus RTU

Follow motor manufacturer wiring requirements.

Functions can be programmed remotely using the protocol

software and RS485 connection, or in parameter group 8-**

Communications and Options.

Selecting a

specic communication protocol changes

various default parameter settings to match the speci-

cations of the protocol and makes extra protocol-specic

parameters available.

Electrical Installation

VLT

®

AutomationDrive FC 360

20 Danfoss A/S © 03/2017 All rights reserved. MG06A702

44

Loading...

Loading...