A negative response may look like this:

Byte Value

PCV

PCA 1 70

PCA 2 00

IND 3 00

IND 4 00

PVA 5 00

PVA 6 00

PVA 7 00

PVA 8 02

PCD

STW 9 0F

STW 10 07

MAV 11 20

MAR 12 00

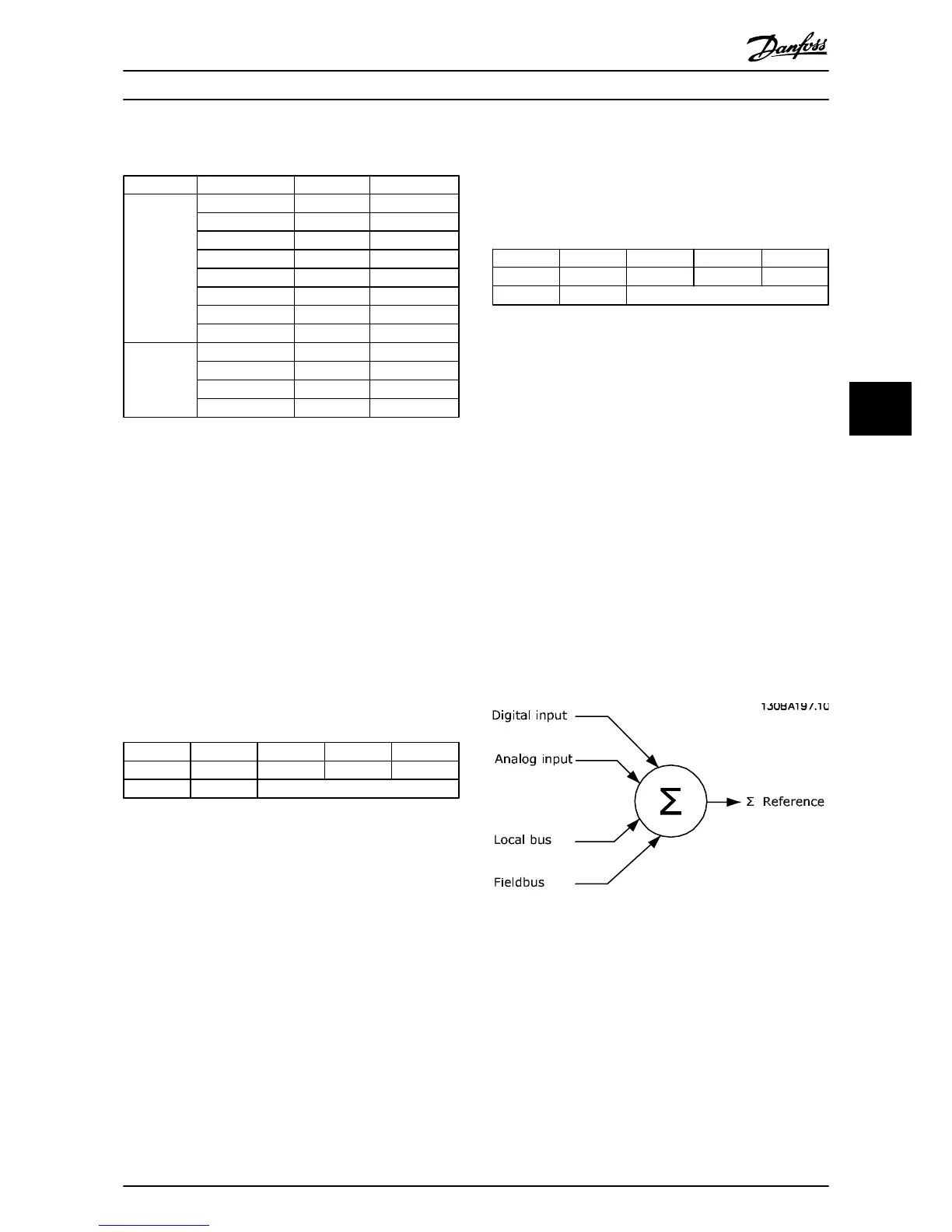

Table 6.8 Negative Response

RC is 7 Hex, which means that the request has been

rejected, and the fault number can be found in the PVA

part. In this case the fault number is 2, which means that

the upper or lower limit of the parameter is exceeded, see

Table 6.5.

6.3

Process Data

Use the process data part of the PPO for controlling and

monitoring the frequency converter via the PROFINET.

6.3.1

Process Control Data

Process data sent from the PLC to the frequency converter

are defined as Process Control Data (PCD).

0

1 2 ...... 9

CTW MRV PCD ...... PCD

PCD write

Table 6.9 Master Slave

PCD 0 contains a 16-bit control word, where each bit

controls a specific function of the frequency converter, see

chapter 6.4 Control Profile. PCD 1 contains a 16-bit speed

set point in percentage format. See chapter 6.3.3 Reference

Handling.

The content of PCD 2 to PCD 9 is programmed in 9-15 PCD

Write Configuration and 9-16 PCD Read Configuration.

6.3.2

Process Status Data

Process data sent from the frequency converter contain

information about the current state of the frequency

converter.

0 1 2 ...... 9

STW MAV PCD ...... PCD

PCD read

Table 6.10 Slave Master

PCD 0 contains a 16-bit status word, where each bit

contains information regarding a possible state of the

frequency converter.

PCD 1 contains per default the value of the current speed

of the frequency converter in percentage format (see

chapter 6.3.3 Reference Handling).

The content of PCD 2 to PCD 9 is programmed in 9-16 PCD

Read Configuration.

6.3.3

Reference Handling

The reference handling in FC 102/FC 202/FC 301/FC

302/FCD 302 is an advanced mechanism that sums up

references from different sources.

For more information on reference handling, refer to the

FC 102/FC 202/FC 301/FC 302/FCD 302 Design Guides.

Illustration 6.1 Reference Handling

The reference, or speed set point (MRV, send via PROFINET

is always transmitted to the frequency converter in

percentage format as integers represented in hexadecimal

(0-4000 hex).

How to Control the Frequenc...

Operating Instructions

MG90U302 Danfoss A/S © Rev. 2014-02-27 All rights reserved. 29

6 6